Preparation and redissolution method of composite curcumin-myofibrillar protein solid beverage

A myofibrillar protein and curcumin muscle technology, which is applied in the field of compound curcumin myofibrillar protein solid drink preparation and reconstitution, can solve the problems of uneven dissolution of curcumin, influence on absorption effect, poor uniformity, etc., and achieve Brewing is convenient and diverse, easy to absorb by the human body, and has good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

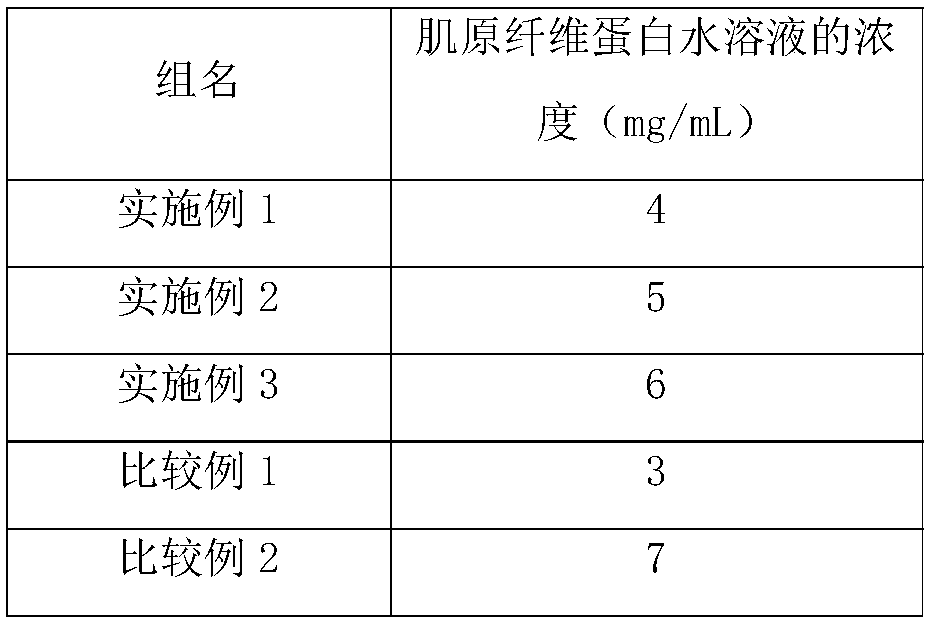

Embodiment 1~3 and comparative example 1、2

[0032] A kind of composite curcumin myofibrillar protein solid beverage preparation method that embodiment 1~3 and comparative example 1,2 provide, concrete steps are:

[0033] S1. For the extraction of myofibrillar protein, take 100 g of minced chicken breast and mix it with 10 times the volume of cold buffer solution, stir evenly, and centrifuge to get the precipitate Ⅰ;

[0034] Add 0.1mol / L NaCl solution 5 times the volume of the precipitate I, stir evenly, homogenize, centrifuge, and take the precipitate II;

[0035] Adding the NaCl solution 5 times the volume of the precipitate II, homogenizing again, filtering, and centrifuging in order, taking the precipitate III, washing with cold distilled water to collect the final product, namely myofibrillar protein;

[0036] The above steps are all carried out at 4°C, the homogenization is 8000rpm for 10min, the centrifugation is 10000g for 10min, and the NaCl concentration in the cold buffer solution is 25mmol / L; the cold buffer...

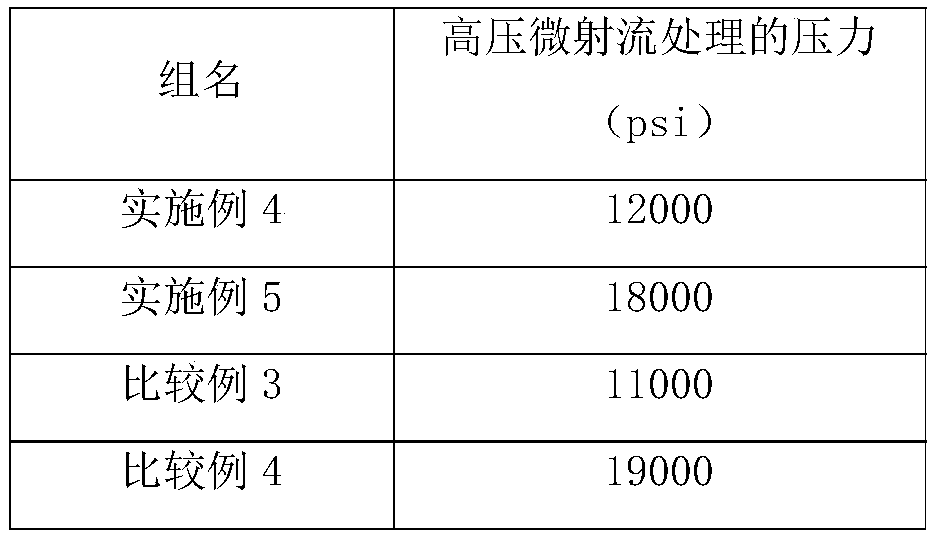

Embodiment 4、5 and comparative example 3、4

[0044] A kind of composite curcumin myofibrillar protein solid beverage preparation method that embodiment 4,5 and comparative example 3,4 provide, concrete steps are:

[0045] S1. For the extraction of myofibrillar protein, take 100 g of minced chicken breast and mix it with 10 times the volume of cold buffer solution, stir evenly, and centrifuge to get the precipitate Ⅰ;

[0046] Add 0.1mol / L NaCl solution 5 times the volume of the precipitate I, stir well, homogenize, centrifuge, and take the precipitate II;

[0047] Adding the NaCl solution 5 times the volume of the precipitate II, homogenizing again, filtering, and centrifuging in order, taking the precipitate III, washing with cold distilled water to collect the final product, namely myofibrillar protein;

[0048]The above steps are all carried out at 4°C, the homogenization is 8000rpm for 10min, the centrifugation is 10000g for 10min, and the NaCl concentration in the cold buffer solution is 25mmol / L; the cold buffer an...

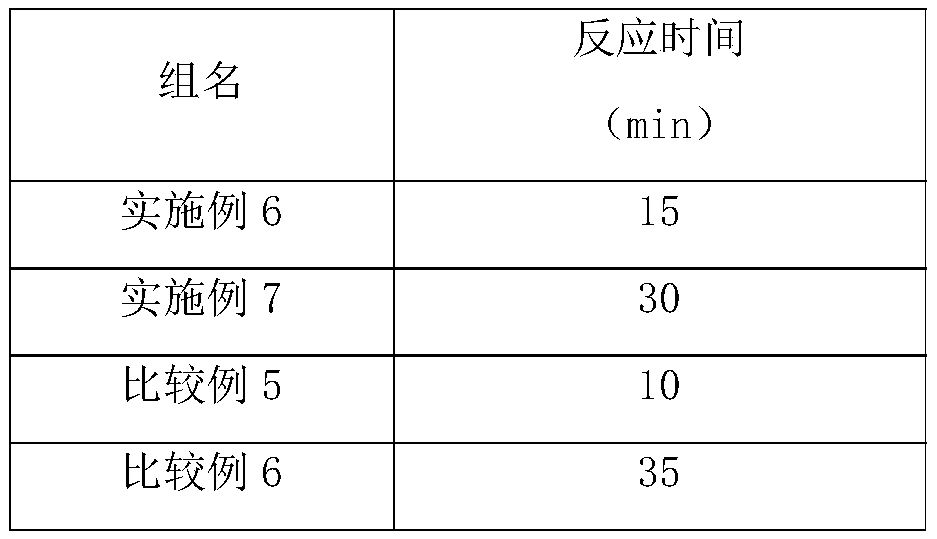

Embodiment 6、7 and comparative example 5、6

[0056] A kind of composite curcumin myofibrillar protein solid beverage preparation method that embodiment 6,7 and comparative example 5,6 provide, concrete steps are:

[0057] S1. For the extraction of myofibrillar protein, take 100 g of minced chicken breast and mix it with 10 times the volume of cold buffer solution, stir evenly, and centrifuge to get the precipitate Ⅰ;

[0058] Add 0.1mol / L NaCl solution 5 times the volume of the precipitate I, stir evenly, homogenize, centrifuge, and take the precipitate II;

[0059] Adding the NaCl solution 5 times the volume of the precipitate II, homogenizing again, filtering, and centrifuging in order, taking the precipitate III, washing with cold distilled water to collect the final product, namely myofibrillar protein;

[0060] The above steps are all carried out at 4°C, the homogenization is 8000rpm for 10min, the centrifugation is 10000g for 10min, and the NaCl concentration in the cold buffer solution is 25mmol / L; the cold buffer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com