Adsorbent, preparation method and application thereof

An adsorbent and reaction technology, applied in the field of adsorbent preparation, can solve the problems of low adsorption efficiency of adsorbent, high toxicity of raw materials, etc., and achieve the effects of low price, low production cost and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of adsorbent of the present invention specifically comprises:

[0028] Step 1: Mix carboxymethyl cellulose solution and gelatin solution according to the above ratio, and heat at 30-60° C. for 30-120 minutes to obtain a mixed solution. A 0.2% (w / v) solution of carboxymethylcellulose and a 4% (w / v) solution of gelatin are preferred.

[0029] Step 2: Add the pyrrole monomer to the mixed solution in step 1 and stir evenly, then add chromic acid as an oxidizing agent to initiate the polymerization of the pyrrole monomer, and react at 10-30°C for 12-24 hours to obtain carboxymethylcellulose / gelatin / polymer Pyrrole hydrogel, namely the adsorbent of the present invention;

[0030] Wherein, the mass ratio of pyrrole monomer to chromic acid is 67:118-0.236, and the mass concentration (w / v) of pyrrole monomer in the mixed solution is 0.136%-1.36%. Preferably, the mass ratio of pyrrole monomer to chromic acid is 67:5.31, and the mass concentration of pyrro...

Embodiment 1

[0035] Heat and mix 0.2% (w / v) carboxymethyl cellulose solution and 4% (w / v) gelatin solution at 50° C. for 60 min to obtain a mixed solution. Add the pyrrole monomer into the mixed liquid and stir evenly, wherein the mass concentration (w / v) of the pyrrole monomer in the mixed liquid is 0.67%. Then add chromic acid according to the mass ratio of pyrrole monomer to chromic acid as 67:5.31, as an oxidant to initiate the polymerization of pyrrole monomer, and react at 20°C for 16 hours to obtain carboxymethyl cellulose / gelatin / polypyrrole hydrogel Gel (CMC / Gel / PPy). The hydrogel obtained by the reaction was first treated with NaHCO 3 The solution was eluted for about 30 minutes, and then washed several times with water to obtain the adsorbent.

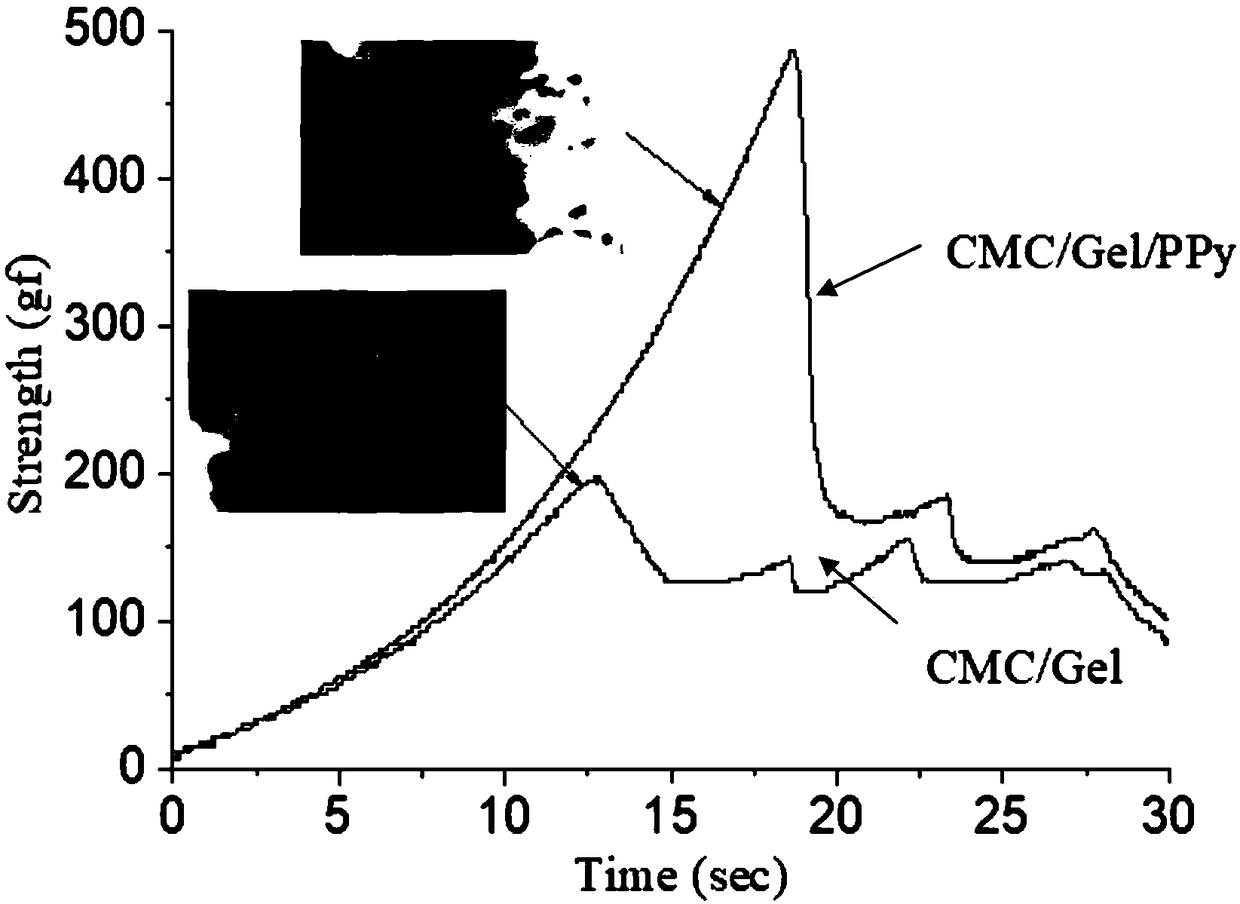

[0036] The prepared adsorbent was tested for mechanical properties, and the test structure was as follows: figure 1 shown, from figure 1 It can be seen that the cross-linking of polypyrrole can more than double the mechanical propertie...

Embodiment 2

[0040] Heat and mix 0.2% (w / v) carboxymethyl cellulose solution and 4% (w / v) gelatin solution at 40° C. for 120 min to obtain a mixed solution. Add the pyrrole monomer into the mixed liquid and stir evenly, wherein the mass concentration (w / v) of the pyrrole monomer in the mixed liquid is 1.36%. Then add chromic acid according to the mass ratio of pyrrole monomer to chromic acid as 67:0.236, as an oxidant to initiate the polymerization of pyrrole monomer, and react at 30°C for 12 hours to obtain carboxymethyl cellulose / gelatin / polypyrrole hydrogel Gel (CMC / Gel / PPy). The hydrogel obtained by the reaction was first treated with NaHCO 3 The solution was eluted for about 60 minutes, and then washed several times with water to obtain the adsorbent.

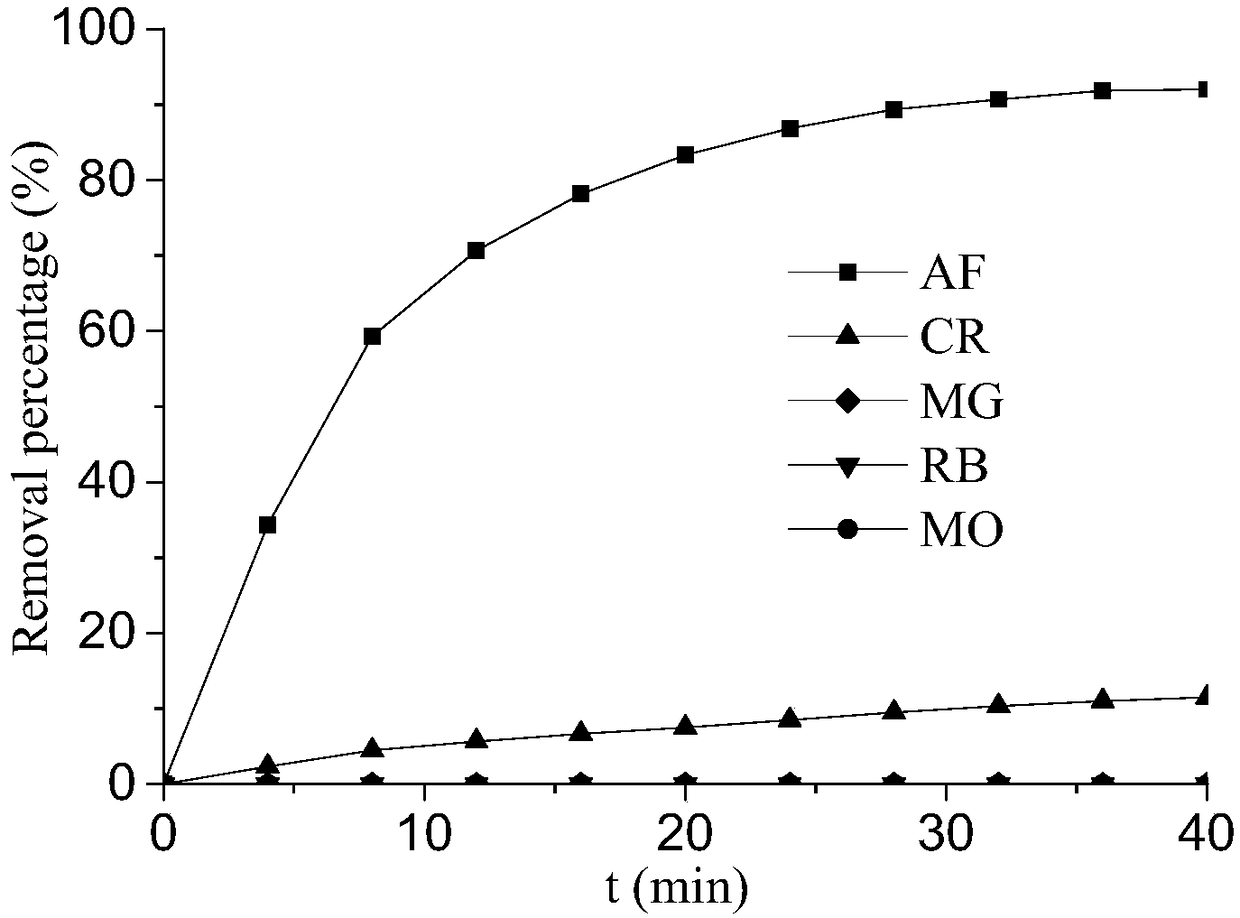

[0041] Using the adsorbent obtained in this example to adsorb the 60 mg / L acid fuchsin dye solution, the adsorption capacity can reach 94% (the adsorption capacity is slightly increased compared with Example 1). After adsorption, pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com