Flocculating agent with bactericidal function

A flocculant and functional technology, applied in the field of flocculant with bactericidal function, can solve the problems of difficult to meet the discharge standard, insufficient water purification effect, weak bactericidal ability, etc., to achieve inhibition of bacterial growth, strong bactericidal effect, and water purification powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

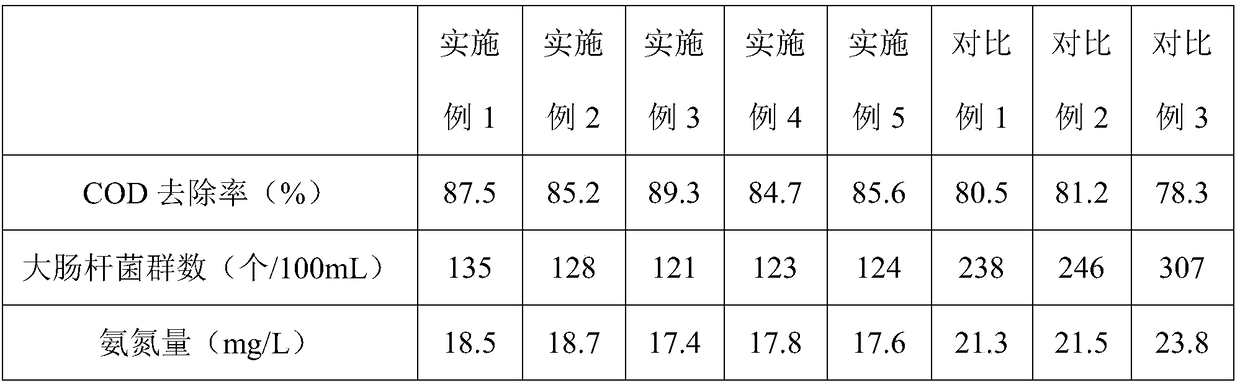

Examples

Embodiment 1

[0022] A flocculant with bactericidal function, comprising the following raw materials in parts by weight: 20 parts of aluminum sulfate, 8 parts of sodium silicate, 15 parts of polyferric sulfate, 6 parts of chitosan, 5 parts of sepiolite, 1 part of zeolite, 5 parts of glacial acetic acid, 3 parts of epichlorohydrin, 8 parts of alcohol compounds, and 80 parts of water.

[0023] Wherein, the molecular weight of the chitosan is 200,000.

[0024] Wherein, the alcohol compound is one or more of methanol, ethanol and isopropanol.

[0025] In this embodiment, the method for preparing the flocculant with sterilization function includes the following steps:

[0026] 1) Sepiolite and zeolite are respectively crushed and passed through an 80-mesh sieve to obtain sepiolite and zeolite powder;

[0027] 2) Add aluminum sulfate and sodium silicate to water and mix, heat to 50°C, stir evenly, adjust the pH to 3, then add polyferric sulfate and stir, then add alcohol compounds, stir evenly to obtain m...

Embodiment 2

[0032] A flocculant with bactericidal function, comprising the following raw materials in parts by weight: 22 parts of aluminum sulfate, 9 parts of sodium silicate, 16 parts of polyferric sulfate, 6.5 parts of chitosan, 5.5 parts of sepiolite, 1.5 parts of zeolite, 7 parts of glacial acetic acid, 4.5 parts of epichlorohydrin, 9.5 parts of alcohol compounds, 95 parts of water.

[0033] Wherein, the molecular weight of the chitosan is 200,000.

[0034] Wherein, the alcohol compound is one or more of methanol, ethanol and isopropanol.

[0035] In this embodiment, the method for preparing the flocculant with sterilization function includes the following steps:

[0036] 1) Sepiolite and zeolite are respectively crushed and passed through a 90-mesh sieve to obtain sepiolite and zeolite powder;

[0037] 2) Add aluminum sulfate and sodium silicate to water and mix, heat up to 55°C, stir evenly, adjust the pH to 4, then add polyferric sulfate and stir, then add alcohol compounds, stir evenly to...

Embodiment 3

[0042] A flocculant with bactericidal function, comprising the following raw materials in parts by weight: 25 parts of aluminum sulfate, 10 parts of sodium silicate, 17 parts of polyferric sulfate, 7 parts of chitosan, 6 parts of sepiolite, 2 parts of zeolite, 6.5 parts of glacial acetic acid, 4 parts of epichlorohydrin, 9 parts of alcohol compounds, 90 parts of water.

[0043] Wherein, the molecular weight of the chitosan is 200,000.

[0044] Wherein, the alcohol compound is one or more of methanol, ethanol and isopropanol.

[0045] In this embodiment, the method for preparing the flocculant with sterilization function includes the following steps:

[0046] 1) Sepiolite and zeolite are respectively crushed and passed through a 90-mesh sieve to obtain sepiolite and zeolite powder;

[0047] 2) Add aluminum sulfate and sodium silicate to water and mix, heat up to 55°C, stir evenly, adjust the pH to 4, then add polyferric sulfate and stir, then add alcohol compounds, stir evenly to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com