Flue gas desulfurization regeneration integrated tower and renewable wet flue gas desulfurization method

A flue gas and integrated technology, applied in separation methods, gas treatment, chemical instruments and methods, etc., can solve problems such as waste of water resources, achieve the effects of lower exhaust gas temperature, lower load, and higher flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

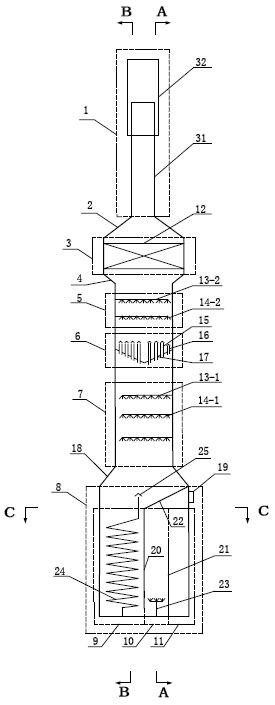

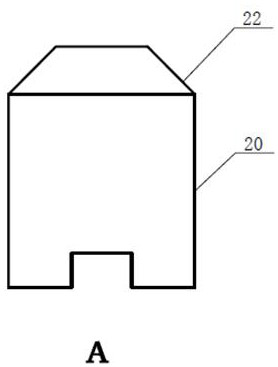

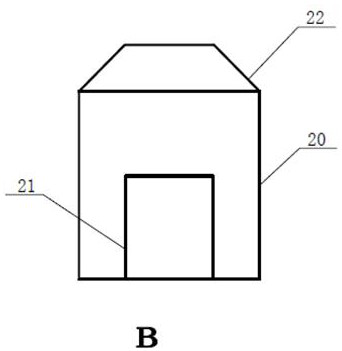

[0068] Flue gas desulfurization and regeneration integrated tower, from top to bottom are flue gas discharge area 1, demister area 3, secondary spray area 5, liquid holding tank area 6, primary spray area 7 and absorption liquid regeneration area 8; The flue gas discharge area 1 and the demister area 3 are preferably connected by a cone-shaped diameter 2, and the tower diameter ratio between the demist area 3 and the flue gas discharge area 1 is 2.5~5; the demist area 3 and the secondary spray area 5 are preferably The tower diameter ratio between the demisting zone 3 and the secondary spraying zone 5 is 1.5; the primary spraying zone 7 and the absorption liquid regeneration zone 8 are preferably connected by a cone-shaped variable diameter 18, and the absorption liquid The tower diameter ratio between the regeneration zone 8 and the primary spray zone 7 is 1.5.

[0069] The absorption liquid regeneration zone 8 is followed by the preheating zone 9, the stripping zone 10 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com