Biological enzyme air purifying agent as well as preparation method and application thereof

An air purifier and bio-enzyme technology, applied in the field of air purification, can solve the problems of limited degree of treatment, side effects, short duration, etc., and achieve the effect of no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

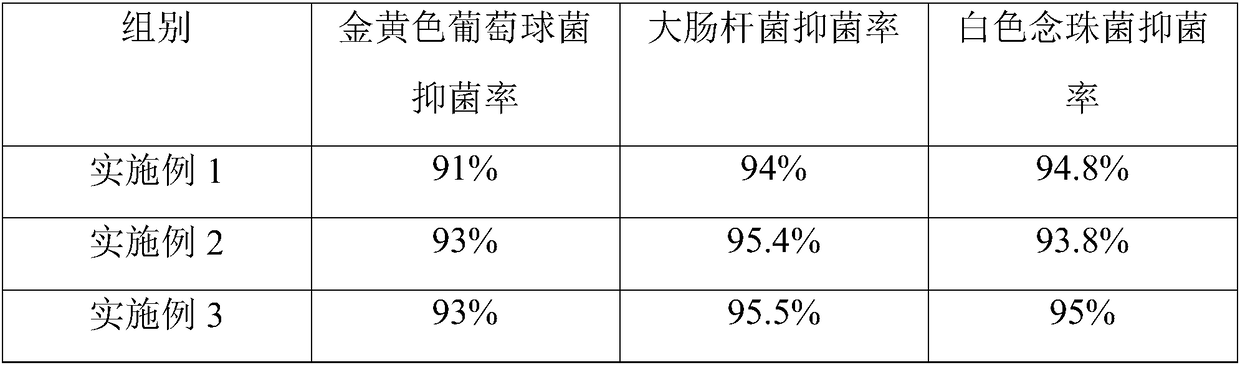

Examples

Embodiment 1

[0037] A preparation method of a biological enzyme air purifier, specifically comprising the following steps:

[0038] (1) Select oxidoreductase, protease, pectinase, lipase and cellulase with enzyme activity ≥ 600U / mg as enzyme species, wherein, 32 parts by weight of oxidoreductase, 23 parts by weight of protease, 18 parts by weight of pectinase part, 16 parts by weight of lipase, 11 parts by weight of cellulase;

[0039] (2) At 15°C, add each enzyme to 5 times the weight of deionized water for leaching for 3.5 hours, and take the supernatant for subsequent use;

[0040] (3) At 40°C, mix the supernatants and stir for 30 minutes, then stand at 25°C for 3 hours;

[0041] (4) Under the condition of 0.2MPa, pass the mixed supernatant through an ultrafiltration membrane with a membrane pore size of 0.005um. At this time, the activity unit of the enzyme solution reaches 2500-3000U / mL, and pass the enzyme solution through a 0.005um ultrafiltration membrane again. filter membrane, ...

Embodiment 2

[0046] A preparation method of a biological enzyme air purifier, specifically comprising the following steps:

[0047] (1) Select oxidoreductase, protease, pectinase, lipase and cellulase of enzyme activity ≥ 600U / mg as enzyme kind, wherein, 28 parts by weight of oxidoreductase, 25 parts by weight of protease, 19 parts by weight of pectinase part, 18 parts by weight of lipase, 10 parts by weight of cellulase;

[0048] (2) At 20°C, add each enzyme to 8 times the weight of deionized water for leaching for 4 hours, and take the supernatant for subsequent use;

[0049] (3) At 35°C, mix the supernatants and stir for 40 minutes, then stand at 25°C for 5 hours;

[0050](4) Under the condition of 0.5MPa, pass the mixed supernatant through an ultrafiltration membrane with a membrane pore size of 0.008um. At this time, the activity unit of the enzyme solution reaches 2500-3000U / mL, and pass the enzyme solution through a 0.008um ultrafiltration membrane again. filter membrane, and refi...

Embodiment 3

[0055] A preparation method of a biological enzyme air purifier, specifically comprising the following steps:

[0056] (1) Select oxidoreductase, protease, pectinase, lipase and cellulase with enzyme activity ≥ 600U / mg as enzyme species, wherein, 34 parts by weight of oxidoreductase, 20 parts by weight of protease, 20 parts by weight of pectinase part, 16 parts by weight of lipase, 10 parts by weight of cellulase;

[0057] (2) At 10°C, add each enzyme to 10 times the weight of deionized water for leaching for 5 hours, and take the supernatant for later use;

[0058] (3) At 50°C, mix the supernatants and stir for 45 minutes, then stand at 20°C for 4.5 hours;

[0059] (4) Under the condition of 0.1MPa, pass the mixed supernatant through an ultrafiltration membrane with a membrane pore size of 0.01um. At this time, the activity unit of the enzyme solution reaches 2500-3000U / mL, and pass the enzyme solution through a 0.01um ultrafiltration membrane again. filter membrane, and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com