Preparation method of carbon-doped BiOI/BiOIO3 heterostructure

A technology of bismuth iodide bismuth iodate and heterostructure, which is applied in separation methods, chemical instruments and methods, gas treatment and other directions, can solve problems such as poor technical effects, achieve significant social and economic benefits, reduce emissions, and optimize Effects of preparation process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

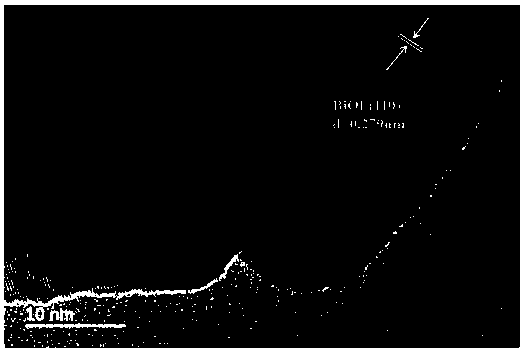

[0026] A Fabrication Method of Carbon-doped BiOI / BiOIO3 Heterostructure, BiOI and BiOIO 3 The heterostructure is conducive to the separation of photogenerated electron-hole pairs, and it exhibits high photocatalytic activity in mercury removal experiments under visible light conditions;

[0027] The preparation method of this catalyst comprises the following steps:

[0028] (1) 0.485g of Bi(NO 3 ) 3 ·5H 2 O was added to 80ml of deionized water, and continued magnetic stirring for 20min to obtain a mixed liquid;

[0029] (2) 0.214g of KIO 3 Dissolve in the above mixed liquid, and continue magnetic stirring for 2h to obtain the mixed liquid;

[0030] (3) Dissolving 0.0054 g of glucose in the mixed liquid of step (2), and continuing magnetic stirring for 1 h;

[0031] (4) Place the above solution in a hydrothermal reaction kettle, and heat it in water at a temperature of 160° C. for 6 hours to obtain the product;

[0032] (5) The product obtained in step (4) is washed thre...

Embodiment 2

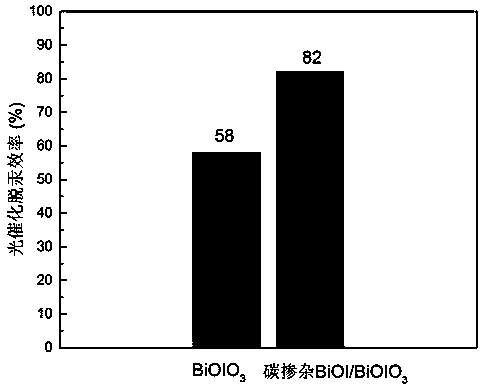

[0038] A carbon-doped BiOI / BiOIO 3 Preparation methods of heterostructures, BiOI and BiOIO 3 The heterostructure is conducive to the separation of photogenerated electron-hole pairs, and it exhibits high photocatalytic activity in mercury removal experiments under visible light conditions;

[0039] The preparation method of this catalyst comprises the following steps:

[0040] (1) Take by weighing the carbon-doped BiOI / BiOIO obtained in 0.02g embodiment 1 3 The heterostructure catalyst was dissolved in 5ml of deionized water, sprayed evenly on the glass plate after ultrasonication, and dried at 80°C for 10 minutes;

[0041](2) Place a 9W LED lamp 10cm above the glass sheet, open the main path of the photocatalytic mercury removal bench, and close the bypass;

[0042] (3) After the mercury concentration is stable in the dark, turn on the 9W LED light, save the data and turn off the LED light after the mercury concentration is stable;

[0043] (4) Weigh 0.02g pure BiOIO 3 R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com