Saggar loading and unloading comprehensive treatment robot and working method thereof

A comprehensive processing and robotic technology, applied in electrode heat treatment, manipulators, manufacturing tools, etc., can solve the problems of mixing foreign matter, raw materials easily contaminated, dust and high temperature diffusion surface, etc., to avoid moisture absorption, better cleaning effect, The effect of improving labor efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

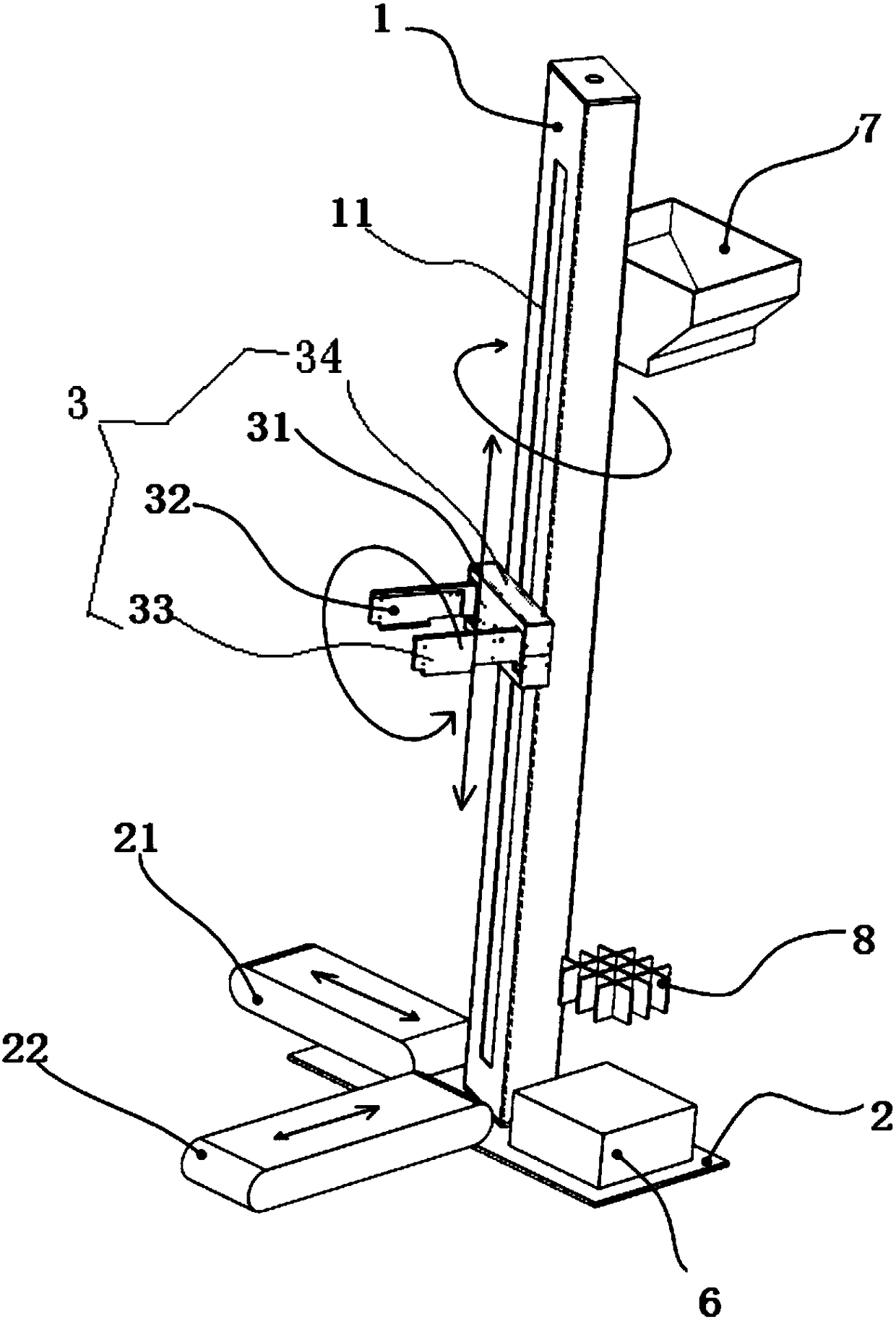

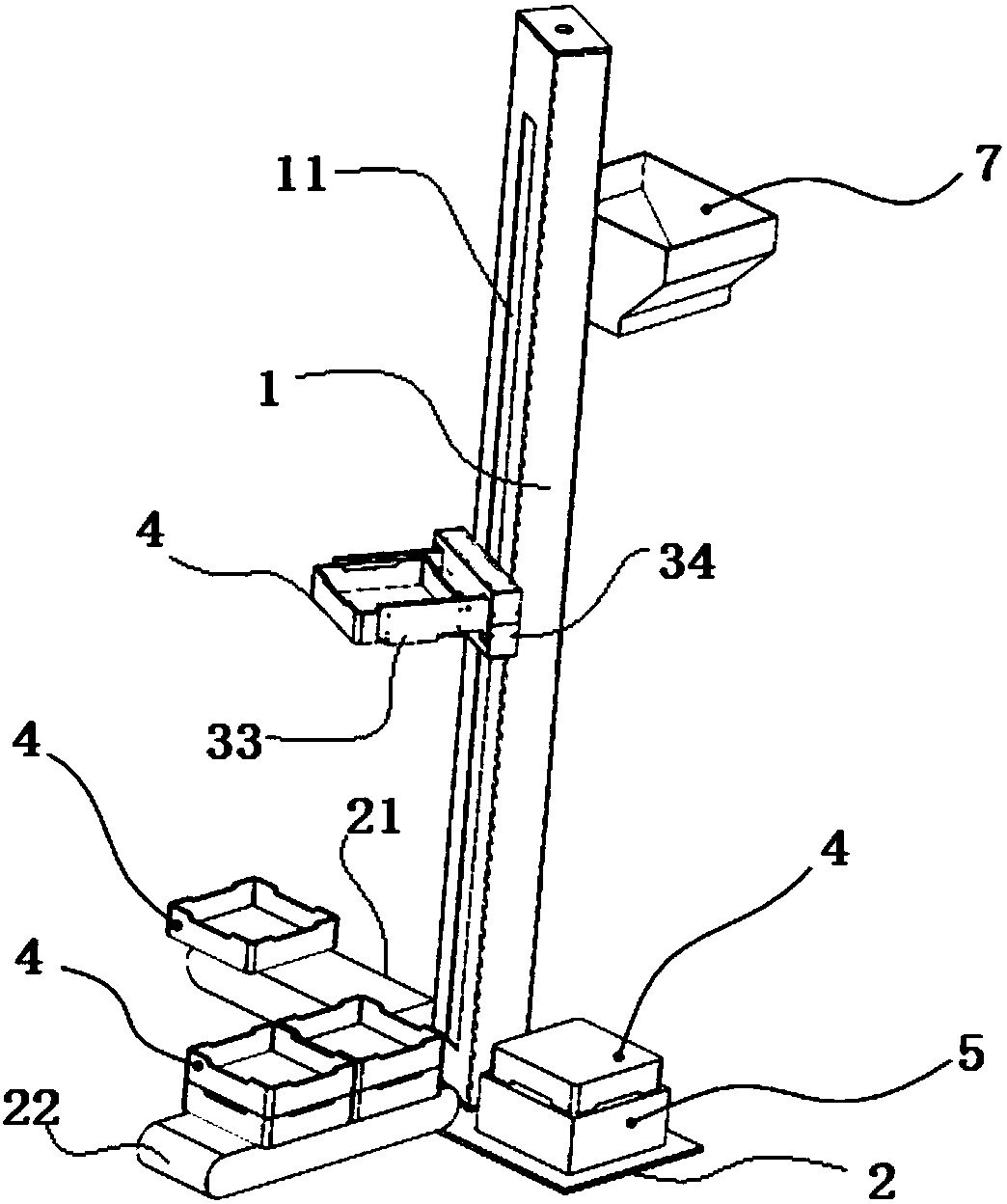

[0038] Example 1 as figure 1 and figure 2 As shown, the comprehensive processing robot for loading and unloading saggers in this embodiment includes a fixed base 2 and a vertical pole 1. The vertical pole 1 includes a rectangular parallelepiped housing 12, and the bottom end of the housing 12 is provided with a vertical pole rotating shaft 13. The vertical rod rotating shaft 13 cooperates with the fixed base 2 bearings, and the fixed base 2 is provided with a first motor for driving the vertical rod rotating shaft 13 to rotate, and the output shaft of the first motor is matched with the vertical rod rotating shaft 13 through a belt drive (in other In the embodiment, the transmission and cooperation can be carried out through the meshed gear sets), so that when the first motor rotates, it can drive the vertical rod 1 to rotate 360 degrees on the fixed base 2 .

[0039] The front end of the pole 1 is provided with a manipulator 3 that can be lifted, such as image 3 and F...

Embodiment 2

[0049] On the basis of Example 1, such as Figure 6 to Figure 8 As shown, there are the following differences between the comprehensive processing robot for loading and unloading saggers in this embodiment and the comprehensive processing robot for loading and unloading saggers in Embodiment 1:

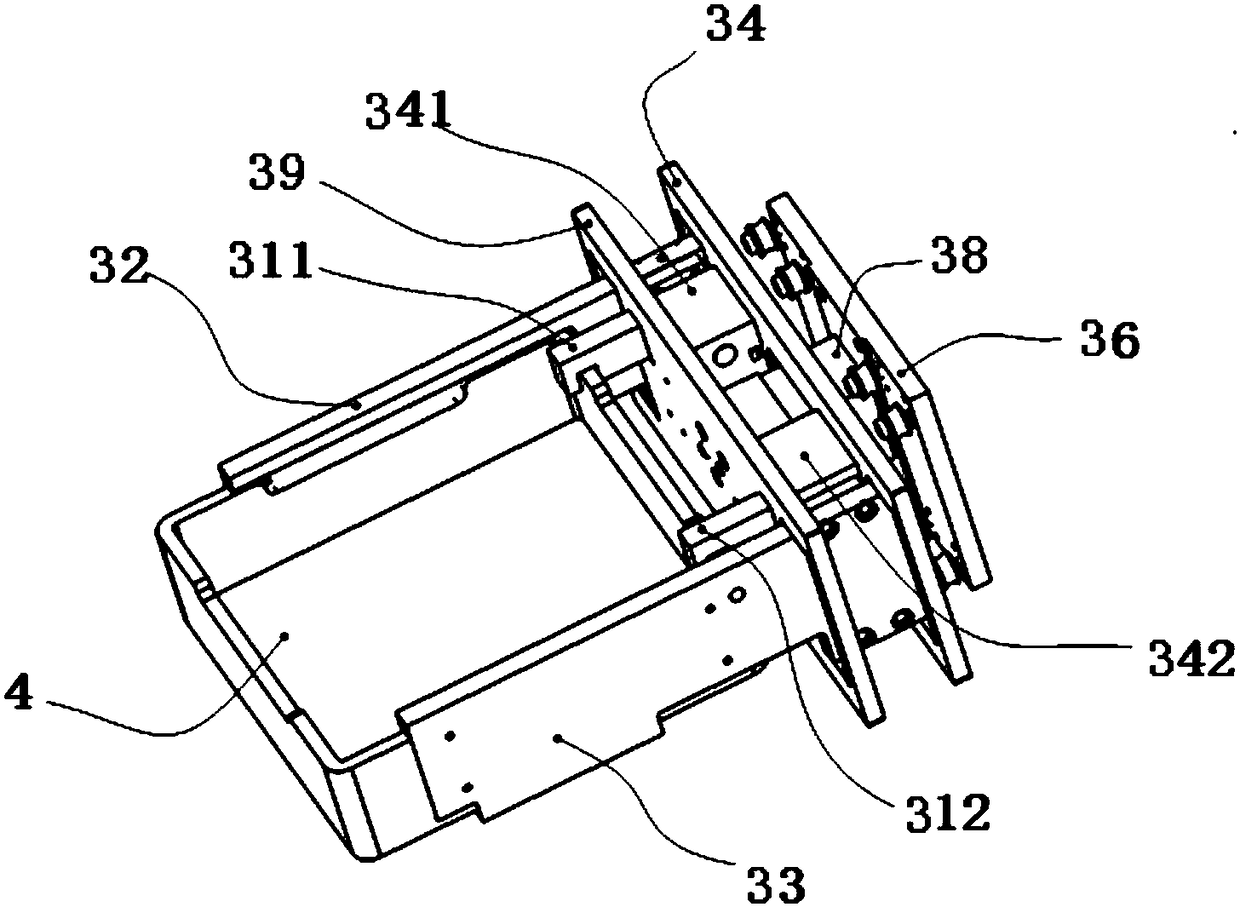

[0050] Manipulator 3 is a rotating manipulator, comprising mounting base 31, left clamp arm 32, right clamping arm 33, base 36, rotary cylinder 35, mounting base 31 comprising front mounting plate 39 and rear mounting plate 34 of the same structure, rear mounting plate 34 and Between the bases 36, the rotating cylinder 35 is used for transmission and cooperation. The tail end of the rotating cylinder 35 is placed in the housing 12 and fixedly connected with the front end of the base 36. The front end of the rotating cylinder 35 passes through the chute 11, and the rotating The output shaft 351 of the rotating cylinder of the cylinder 35 is fixedly connected with the rear end surface o...

Embodiment 3

[0054] The working method of the loading and unloading comprehensive processing robot of the sagger loading and unloading material as embodiment 1, comprises the steps:

[0055] A. Grab the empty sagger 4, which specifically includes placing the empty sagger 4 to be loaded on the longitudinal transport line 21 and transported by the longitudinal transport line 21 to one end adjacent to the vertical pole 1, and starting the rotating motor to drive the vertical pole 1 to rotate Make the weighing manipulator 3 point to the direction of the longitudinal transport line 21, the left jaw arm cylinder 341 and the right jaw arm cylinder 342 are extended synchronously so that the left jaw arm 32 and the right jaw arm 33 are opened, and the lifting motor 14 is started to make the weighing manipulator 3 descend When the empty sagger 4 is placed between the left clamp arm 32 and the right clamp arm 33 and the edge of the sagger 4 is engaged in the inverted U-shaped slot at the front ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com