Nb2O5 doped BaTiO3 substrate-type PTC thermal sensitive ceramic and preparation method thereof

A heat-sensitive ceramic and substrate technology, which is applied in the field of Nb2O5-doped BaTiO3-based PTC heat-sensitive ceramics and its preparation, can solve the problems of low lift-to-drag ratio, achieve low room temperature resistance, widen the semiconducting range, and The effect of lift-to-drag ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) BaTiO 3 Preparation of substrate-type PTC heat-sensitive material powder

[0025] BaTiO 3 The composition of the substrate-type PTC thermosensitive material is according to the following formula:

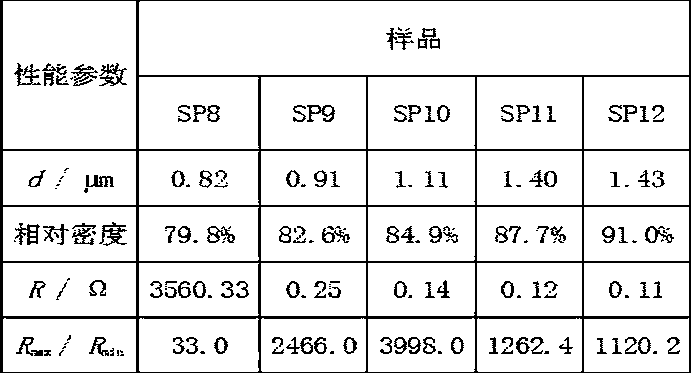

[0026] Ba m (Ti 1-x Nb x )O 3 + y SiO 2 , where m = 0.994, 0.997, 1.000, 1.003, 1.006, 1.012, 1.018mol; x = 0.35mol%; y = 0.05mol%. The corresponding samples were labeled with SP1, SP2, SP3, SP4, SP5, SP6 and SP7, respectively. Weigh the BaCO in turn according to the proportion of the above formula 3 , SiO 2 , Nb 2 o 5 and TiO 2 , the purity of these substances should also be considered when weighing. BaCO 3 , SiO 2 , Nb 2 o 5 and TiO 2 The purity calibration methods are: high temperature deduction method, gravimetric method, high temperature deduction method and redox titration method, and their corresponding purities are: 99.8%, 99.99%, 99.99% and 99.8%. ZrO 2The ball is used as the ball milling medium, and an appropriate amount of deionized water...

Embodiment 2

[0040] (1) BaTiO 3 Preparation of substrate-type PTC heat-sensitive material powder

[0041] Based on Example 1, we can conclude that m When being 1.006, the sheet sample can obtain better PTC characteristics, so, the composition of the sample of the present invention is according to the following formula Ba m (Ti 1-x Nb x )O 3 + y SiO 2 ,in m = 1.006 mol; x = 0.35mol%; y = 0.05 mol%. Corresponding samples were labeled with SP5. Weigh the BaCO in turn according to the proportion of the above formula 3 , SiO 2 , Nb 2 o 5 and TiO 2 , with ZrO 2 The ball was used as the ball milling medium, and an appropriate amount of deionized water was added, and the weighed mixture was put into a high-energy ball mill for ball milling and mixing for 90 min, and the speed of the ball mill was 2400 rpm. Put the ball-milled slurry into an oven at 115°C to dry for 16-18 hours. After drying, put the powder passed through a 45-mesh sieve into a crucible, squeeze it firmly with...

Embodiment 3

[0055] (1) BaTiO 3 Preparation of substrate-type PTC heat-sensitive material powder

[0056] Based on example 1 and example 2, the composition of the sample of the present invention is according to the following formula Ba m (Ti 1-x Nb x )O 3 + y SiO 2 ,in m = 1.006 mol; x = 0.35 mol%; y = 0.05 mol%. Corresponding samples were labeled with SP5. Weigh the BaCO in turn according to the proportion of the above formula 3 , SiO 2 , Nb 2 o 5 and TiO 2 , with ZrO 2 The ball was used as the ball milling medium, and an appropriate amount of deionized water was added, and the weighed mixture was put into a high-energy ball mill for ball milling and mixing for 90 min, and the speed of the ball mill was 2400 rpm. Put the ball-milled slurry into an oven at 115°C to dry for 16 to 18 hours. After drying, put the powder that has passed through a 45-mesh sieve into a crucible, squeeze it firmly with a round lid of the crucible, and then use a fine glass Punch 7 small holes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com