Preparation method of lithium vanadium manganese phosphate positive electrode material

A technology of lithium manganese vanadium phosphate and positive electrode materials, which is applied in the field of lithium-ion batteries, can solve the problems of aggravated electrolyte decomposition, battery cost increase, capacity attenuation, etc., and achieve the effect of improving material performance, excellent performance, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

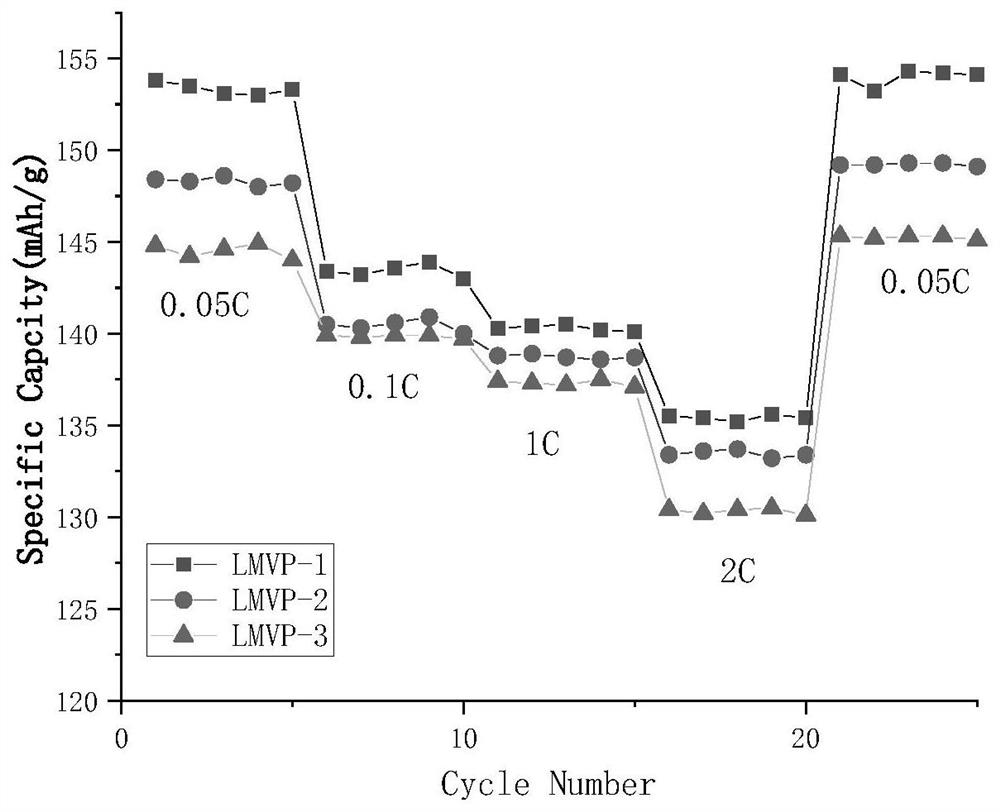

Embodiment 1

[0027] S1, take by weighing 33.22g of manganese sulfate, 85.8g of alum sulfate, 98g of phosphoric acid, add 500ml of ammonia water as a buffer to make a solution, then use lithium hydroxide to adjust the pH=8 of the solution;

[0028] S2. Filter the solution to obtain the precipitate, wash the precipitate repeatedly for 3-10 times and remove the crystal water at 120°C;

[0029] S3. Weigh 25.3g of glucose and 36.2g of lithium carbonate, make the molar ratio of elements Li:Mn:V:P=1.02:0.22:0.44:1, the mass of carbon source is 10wt% of the theoretical product mass, and mix the precursors by pulverizing and grinding received for use;

[0030] S4. Put the collected dry powder material in a continuous sintering furnace, pre-flow nitrogen for 0.5h before sintering to ensure an oxygen-free environment, sinter at a high temperature of 700°C for 7h, absorb exhaust gas during the sintering process; cool the sintered material Afterwards, it is ground and pulverized to form the final prod...

Embodiment 2

[0032] S1. Weigh 25.7g of manganese sulfate, 97.5g of alum sulfate, and 98g of phosphoric acid, add 250ml of ammonia water as a buffer to make a solution, and then use lithium hydroxide to adjust pH=7;

[0033] S2. Filter the solution to obtain the precipitate, wash the precipitate repeatedly for 3-10 times and remove the crystal water at 100°C;

[0034] S3. Weigh 25.7g of glucose and 36.2g of lithium carbonate, so that the molar ratio of elements Li:Mn:V:P=1.02:0.17:0.5:, the quality of carbon source is 10wt% of the theoretical product quality, and the mixed precursor is crushed and collected stand-by;

[0035] S4. Collect the collected dry powder materials and place them in a continuous sintering furnace. Pre-flow nitrogen for 5 hours before sintering to ensure an oxygen-free environment. Sinter at a high temperature of 650°C for 8 hours and absorb tail gas during the sintering process; put the sintered materials After cooling, grind and pulverize to form the final product ...

Embodiment 3

[0037] S1. Weigh 19.6g of manganese sulfate, 103.5g of vanadium sulfate, and 98g of phosphoric acid, add 1000ml of ammonia water as a buffer to make a solution, and then use lithium hydroxide to adjust pH=6;

[0038] S2. Filter the solution to obtain the precipitate, wash the precipitate repeatedly for 3-10 times and remove the crystal water at 200°C;

[0039] S3. Weigh 36.2g of lithium carbonate and 25.7g of glucose, make the element molar ratio Li:Mn:V:P=1.02:0.13:0.53:1, the mass of the carbon source is 10wt% of the theoretical product mass, and mix the precursors by pulverizing and grinding received for use;

[0040]S4. Put the collected dry powder material in a continuous sintering furnace, pre-flow nitrogen for 10 hours before sintering to ensure an oxygen-free environment, sinter at a high temperature of 700°C for 6 hours, absorb exhaust gas during the sintering process; cool the sintered material Grinding and crushing are carried out to form the final product LMVP-3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com