Preparing method of high potential super capacitor electrode material

A technology for supercapacitors and electrode materials, applied in the field of materials and energy, which can solve the problems of poor performance, low tap density, and low working potential of supercapacitors, and achieve the effects of improved performance, low equipment requirements, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Using the rheological phase reaction method, the by-product phosphorus iron Fe of phosphorus chemical industry 1.5 P is iron source and part of phosphorus source, adding a certain amount of NH 4 h 2 PO 4 Supplement the phosphorus source with LiOH·H 2 O and Li 2 CO 3 To mix the lithium source, add ethanol and a certain amount of activated carbon (specific surface area > 100m 2 / g), the precursor is fully ground into a rheological phase, and after low-temperature pretreatment, it is placed in a muffle furnace at 400-900°C for 5-40 hours, and the oxygen in the air is used as the oxygen source to oxidize the carbon burned by C The substance is an inert protective gas, and the black C / LiFePO 4 Electrode material, relatively fluffy, prepared spherical LiFePO 4 Distributed in fine carbon particles, its appearance is as figure 1 shown.

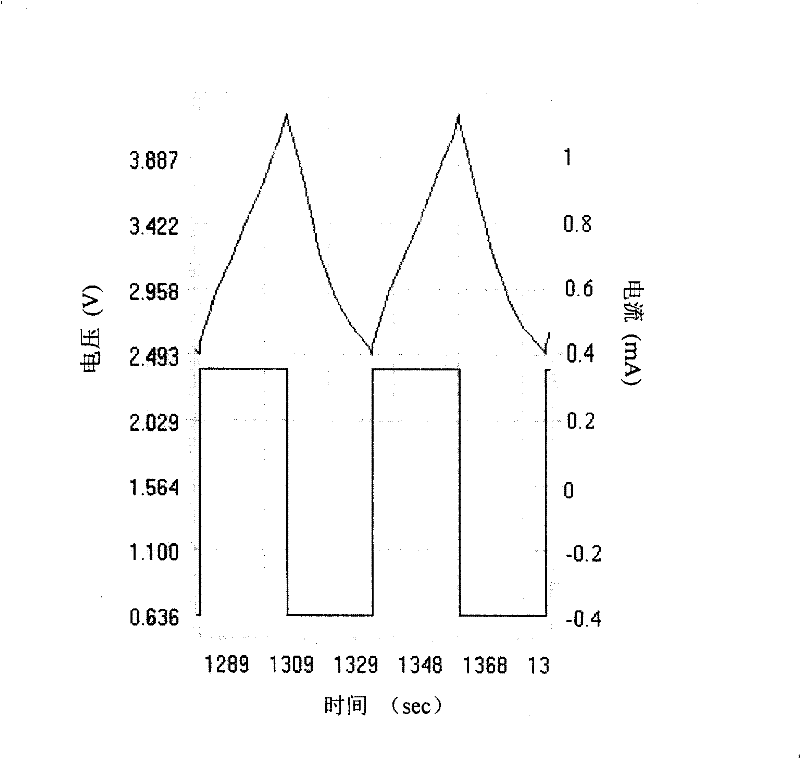

[0026] The prepared above C / LiFePO 4 Electrode material, conductive acetylene black and binder are fully mixed according to the mass...

Embodiment 2

[0028] Using the sol-gel method, Fe(NO 3 ) 3 9H 2 O is iron source, LiH 2 PO 4 For lithium source and phosphorus source, add a certain amount of polyvinyl alcohol, ethanol and water, fully stir at 20-90°C until a viscous colloid is formed, and after further low-temperature pretreatment, put it into a controlled atmosphere tube at 400-900°C Roasting in a type furnace for 5 to 40 hours, using H 2 For the protective gas, the black C / LiFePO was finally obtained 4 electrode material.

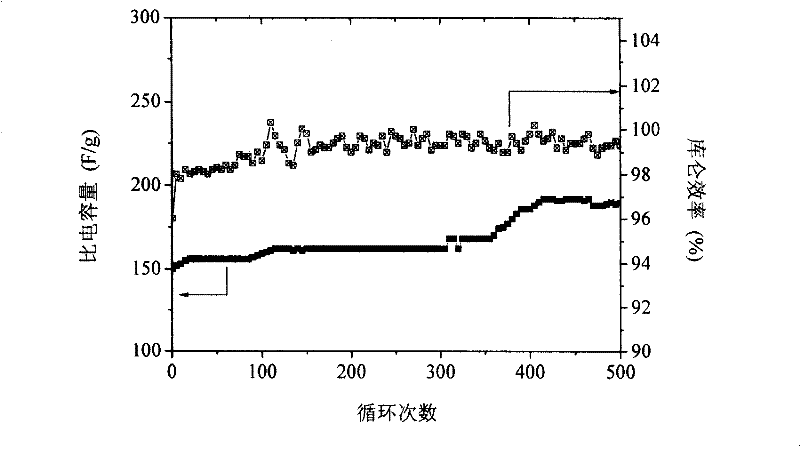

[0029] Using the prepared material as the working electrode, the electrochemical performance test is the same as in Example 1, and the working potential can reach 4.6V. The prepared C / LiFePO 4 The electrode material has good cycle performance, and the cycle performance at 2C is as follows: image 3 As shown, there is no capacity fading after 500 cycles.

Embodiment 3

[0031] Using the reaction pulverization method, FeP was used as the source of iron and phosphorus, and Li 3 PO 4 Lithium source, the ratio of the two substances is 2:1, add a certain amount of sucrose, after high-energy ball milling for 15 hours, put it into a controlled atmosphere tube furnace at 200-800 ° C for 0.5-10 hours to roast. N 2 As an inert protective gas, using oxygen in sucrose as an oxygen source, using the material formation process to carbonize sucrose to obtain black C / Li with controllable carbon content 3 Fe 2 (PO 4 ) 3 electrode material.

[0032] Using the prepared material as the working electrode, the electrochemical performance test is the same as in Example 1, the working potential can reach 4.0V, the stable specific capacitance at 50C can reach 90F / g, and the capacity retention rate after 500 cycles is 96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com