A kind of anti-ultraviolet halogen-free flame-retardant nylon composition for fasteners and its preparation method

A flame-retardant nylon and anti-ultraviolet technology, applied in the field of polymer material modification and processing, to achieve the effect of improving absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

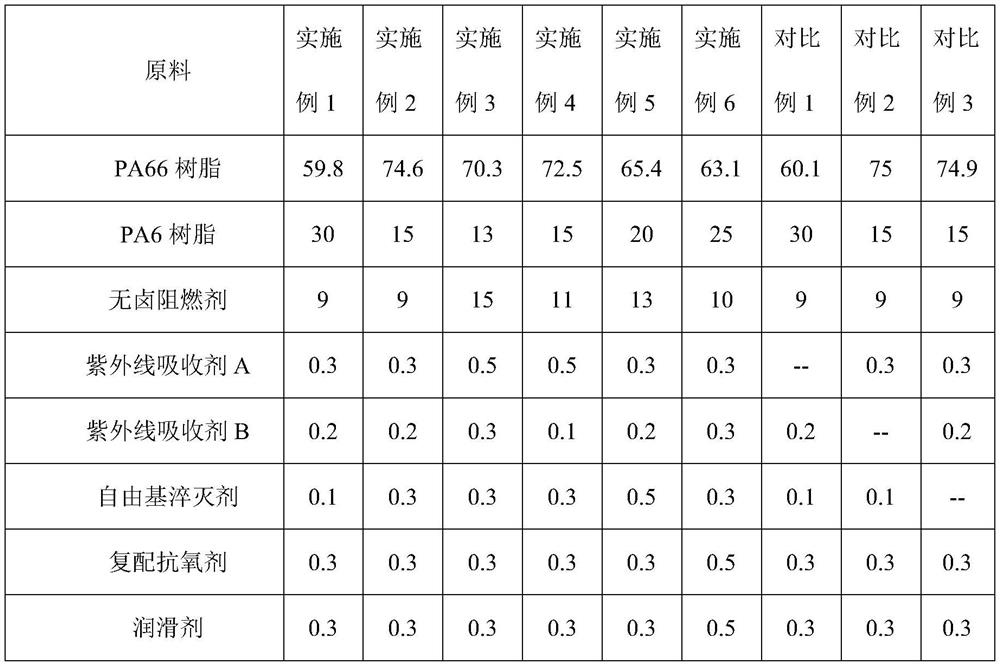

Embodiment 1

[0019] An anti-ultraviolet halogen-free flame-retardant nylon composition for fasteners, comprising the following raw materials: 59.8 parts of PA66 resin, 30 parts of PA6 resin, 9 parts of halogen-free flame retardant, and 0.3 parts of ultraviolet absorber A , 0.2 part of ultraviolet absorber B, 0.1 part of free radical quencher, 0.3 part of compound antioxidant, and 0.3 part of lubricant.

[0020] In order to better demonstrate the preparation process of the UV-resistant halogen-free flame-retardant nylon composition used for fasteners, this example provides a preparation method of a UV-resistant halogen-free flame-retardant nylon composition used for fasteners, including Follow the steps below:

[0021] Step 1: first dry the PA66 and PA6 resins at 90-110°C for 3-6 hours;

[0022] Step 2: Mix the weighed raw materials evenly in a mixer;

[0023] Step 3: Put the mixed raw materials into the lower hopper of the twin-screw extruder, and extrude them from the twin-screw extrude...

Embodiment 2

[0026] An anti-ultraviolet halogen-free flame-retardant nylon composition for fasteners, comprising raw materials of the following components: 74.6 parts of PA66 resin, 15 parts of PA6 resin, 9 parts of halogen-free flame retardant, and 0.3 parts of ultraviolet absorber A , 0.2 parts of ultraviolet absorber B, 0.3 parts of free radical quencher, 0.3 parts of compound antioxidant, and 0.3 parts of lubricant.

[0027] The preparation method of this example is the same as that of Example 1, so it will not be described in detail.

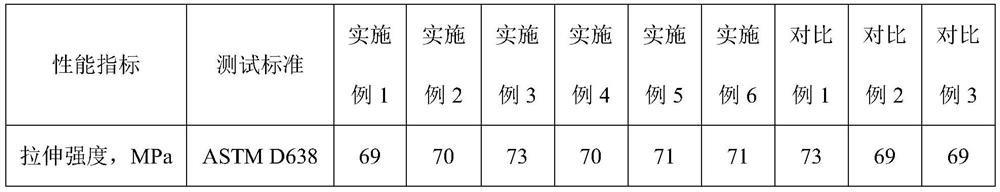

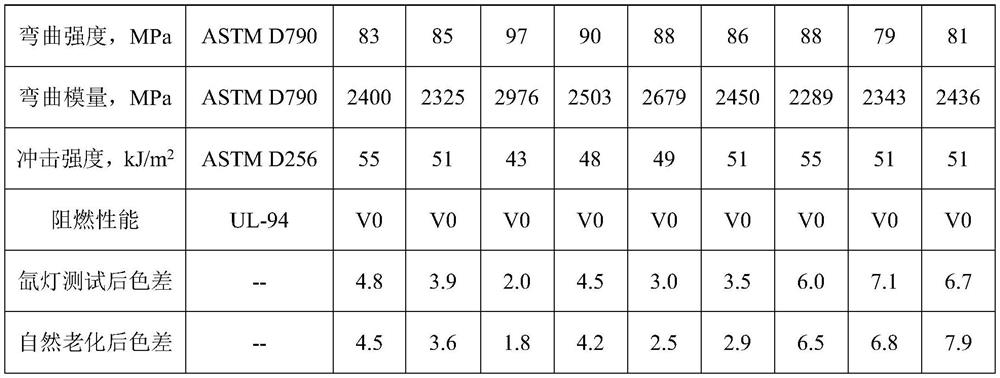

[0028] By performing a performance test on the product prepared in this embodiment, the tensile strength obtained is 70MPa, the flexural strength is 85MPa, the flexural modulus is 2325MPa, and the impact strength is 51kJ / m 2 , flame retardant performance V0, color difference after xenon lamp test is 3.9 and color difference after natural aging is 3.6.

Embodiment 3

[0030] An anti-ultraviolet halogen-free flame-retardant nylon composition for fasteners, comprising the following raw materials: 70.3 parts of PA66 resin, 13 parts of PA6 resin, 15 parts of halogen-free flame retardant, and 0.5 parts of ultraviolet absorber A , 0.3 parts of ultraviolet absorber B, 0.3 parts of free radical quencher, 0.3 parts of compound antioxidant, and 0.3 parts of lubricant.

[0031] The preparation method of this embodiment is the same as that of the above embodiment, so it will not be repeated.

[0032] By performing a performance test on the product prepared in this embodiment, the tensile strength obtained is 73MPa, the flexural strength is 97MPa, the flexural modulus is 2976MPa, and the impact strength is 43kJ / m 2 , flame retardant performance V0, color difference after xenon lamp test is 2.0 and color difference after natural aging is 1.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com