A kind of anti-yellowing weak solvent spray paint and preparation method thereof

A weak solvent, anti-yellowing technology, applied in the direction of coating, etc., can solve the problems of increasing lamination process and production cost, limited amount of anti-aging agent, thick and heavy materials, etc., to achieve vivid and vivid colors of inkjet printing, and prolong anti-aging The effect of uniform performance and whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

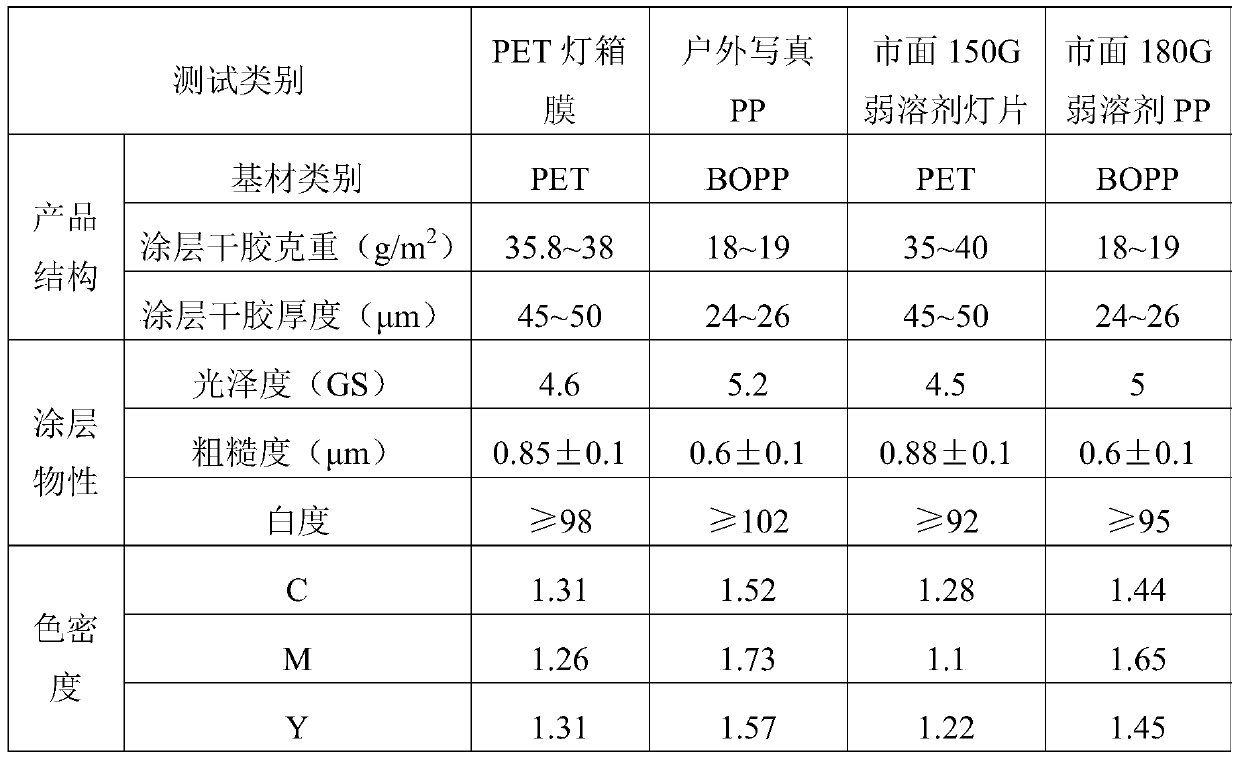

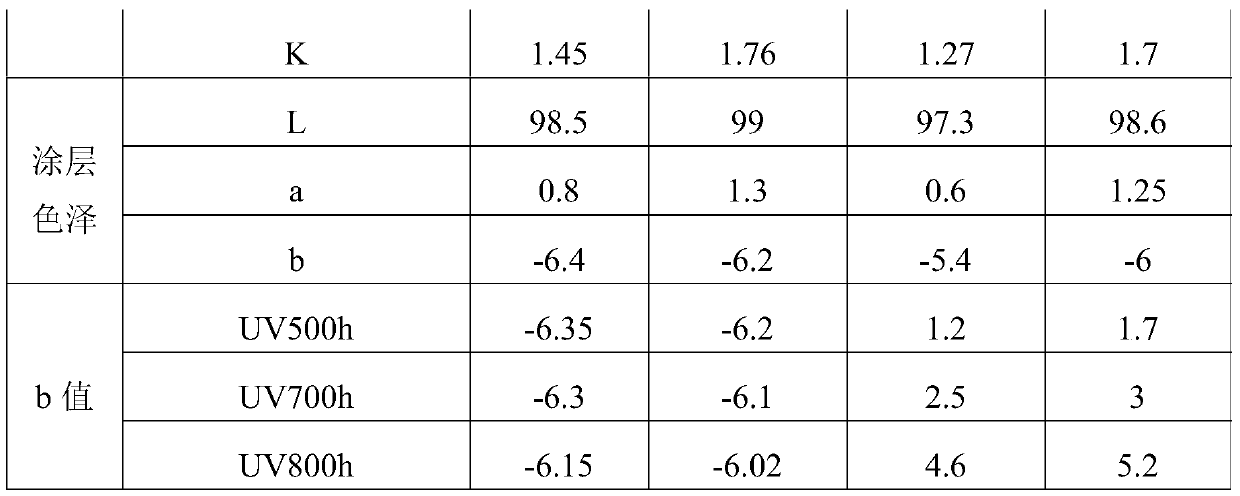

Examples

Embodiment 1

[0029] Anti-yellowing weak solvent spray paint, its raw materials are: 33.4 parts of acrylic acid emulsion, 13.5 parts of polyvinyl alcohol solution (prepared from 11 parts of polyvinyl alcohol and 2.5 parts of deionized water), 9.4 parts of silicon dioxide, 0.5 parts of nano titanium dioxide Sol, 0.17 parts of whitening agent, 0.063 parts of dispersing agent, 0.0017 parts of phthalocyanine blue, 0.0023 parts of permanent violet, 43 parts of deionized water.

[0030] Prepare as follows:

[0031] 1. Prepare polyvinyl alcohol solution: weigh the polyvinyl alcohol granules, add deionized water to the reaction pot, start stirring at a speed of 400r / min, slowly add the polyvinyl alcohol granules, be careful not to form agglomerates, start to heat up after adding, After the temperature reaches 90°C, keep it warm for 1 hour, start cooling to 45°C, filter through a 200-mesh filter, and let it stand for 24 hours for defoaming before use.

[0032] 2. Prepare whitening solution: weigh p...

Embodiment 2

[0035] Anti-yellowing weak solvent spray paint, its raw materials are: 31 parts of acrylic acid emulsion, 15 parts of polyvinyl alcohol solution (prepared from 12 parts of polyvinyl alcohol and 3 parts of deionized water), 8 parts of silicon dioxide, 0.3 parts of nano-titanium dioxide Sol, 0.12 parts of whitening agent, 0.066 parts of dispersing agent, 0.0012 parts of phthalocyanine blue, 0.0033 parts of permanent violet, 40 parts of deionized water.

[0036] Prepare as follows:

[0037] 1. Prepare polyvinyl alcohol solution: weigh the polyvinyl alcohol granules, add deionized water to the reaction pot, start stirring at a speed of 400r / min, slowly add the polyvinyl alcohol granules, be careful not to form agglomerates, start to heat up after adding, After the temperature reaches 90°C, keep it warm for 1 hour, start cooling to 45°C, filter through a 200-mesh filter, and let it stand for 24 hours for defoaming before use.

[0038] 2. Prepare whitening solution: weigh polyvinyl...

Embodiment 3

[0041] Anti-yellowing weak solvent spray paint, its raw materials are: 38 parts of acrylic emulsion, 12 parts of polyvinyl alcohol solution (prepared from 9.5 parts of polyvinyl alcohol and 2.5 parts of deionized water), 12 parts of silicon dioxide, 1 part of nano-titanium dioxide Sol, 0.34 parts of whitening agent, 0.078 parts of dispersant, 0.003 parts of phthalocyanine blue, 0.0025 parts of permanent violet, 50 parts of deionized water.

[0042] Prepare as follows:

[0043] 1. Prepare polyvinyl alcohol solution: weigh the polyvinyl alcohol granules, add deionized water to the reaction pot, start stirring at a speed of 400r / min, slowly add the polyvinyl alcohol granules, be careful not to form agglomerates, start to heat up after adding, After the temperature reaches 90°C, keep it warm for 1 hour, start cooling to 45°C, filter through a 200-mesh filter, and let it stand for 24 hours for defoaming before use.

[0044] 2. Prepare whitening solution: weigh polyvinyl alcohol so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com