A kind of silver alloy bonding wire and its manufacturing method

A technology of silver alloy bond and manufacturing method, which is applied in the field of bonding wire, can solve problems such as unsatisfactory anti-sulfurization performance and anti-aging performance, affecting the service life of bonding wire application products, and high resistivity, so as to increase the bonding operation Window, improve anti-oxidation ability and anti-sulfurization ability, effect of low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

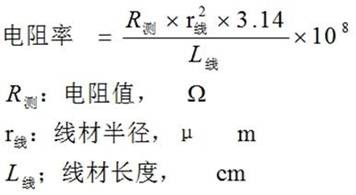

Image

Examples

Embodiment 1

[0031] The silver alloy bonding wire of this embodiment contains Au 1%, Pd 2%, Ca 100ppm, Cu 100ppm, Be 80ppm by weight, and the balance is silver.

[0032] The manufacture method of above-mentioned silver alloy bonding wire comprises the following steps:

[0033] (1) Melting and casting: Au, Pd, Ca, Cu and Be are added to the silver raw material in proportion, and after vacuum melting and directional continuous casting process, a wire rod with a diameter of 6 mm is obtained;

[0034] (2) wire drawing: drawing the wire rod obtained in step (1) to obtain a silver alloy wire with a diameter of 220um;

[0035] (3) Intermediate annealing: After step (2) wire drawing is completed, intermediate annealing is performed on the silver alloy wire, and N 2 As the annealing atmosphere, the effective length of the annealing furnace is 800mm, the annealing temperature is 500°C, and the annealing rate is 100m / min;

[0036] (4) Continue to draw the silver alloy wire after the intermediate an...

Embodiment 2

[0040] The silver alloy bonding wire of this embodiment contains Au 2%, Pd 0.2%, In 50ppm, Ge 150ppm, Ca 10ppm by weight, and the balance is silver.

[0041] The manufacture method of above-mentioned silver alloy bonding wire comprises the following steps:

[0042] (1) Melting and casting: Au, Pd, In, Ge and Ca are added to the silver raw material in proportion, and a wire rod with a diameter of 8 mm is obtained through vacuum melting and directional continuous casting process;

[0043] (2) Wire drawing: drawing the wire rod obtained in step (1) to obtain a silver alloy wire with a diameter of 200um;

[0044] (3) Intermediate annealing: After step (2) wire drawing is completed, intermediate annealing is performed on the silver alloy wire, and N 2 As the annealing atmosphere, the effective length of the annealing furnace is 1000mm, the annealing temperature is 500°C, and the annealing rate is 100m / min;

[0045] (4) Continue to draw the silver alloy wire after the intermediate...

Embodiment 3

[0049] The silver alloy bonding wire of this embodiment contains 0.5% by weight of Au, 3% of Pd, 150ppm of In, 150ppm of Cu, and the balance is silver.

[0050] The manufacture method of above-mentioned silver alloy bonding wire comprises the following steps:

[0051] (1) Melting and casting: Au, Pd, In and Cu are added to the silver raw material in proportion, and after vacuum melting and directional continuous casting process, a wire rod with a diameter of 8 mm is obtained;

[0052](2) Wire drawing: drawing the wire rod obtained in step (1) to obtain a silver alloy wire with a diameter of 150um;

[0053] (3) Intermediate annealing: After step (2) wire drawing is completed, intermediate annealing is performed on the silver alloy wire, and N 2 As the annealing atmosphere, the effective length of the annealing furnace is 600mm, the annealing temperature is 500°C, and the annealing rate is 60m / min;

[0054] (4) Continue to draw the silver alloy wire after the intermediate anne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com