Antistatic ultrahigh-molecular-weight polyethylene fiber material used for packaging mechanical guide rail

An ultra-high molecular weight, polyethylene fiber technology, applied in the field of polyethylene fiber, can solve the problems of complicated preparation process, high fiber static electricity, unfavorable industrialization, etc., and achieve the effects of simplifying the modification process, excellent antistatic, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

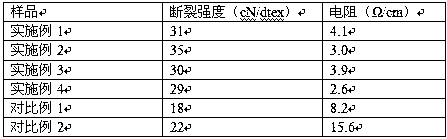

Examples

Embodiment 1

[0031] An antistatic ultra-high molecular weight polyethylene fiber material used for packaging machinery guide rails is prepared by the following method:

[0032] a. Add ultra-high molecular weight polyethylene resin with a weight-average molecular weight of 1.5 million to the solvent decahydronaphthalene, add functional additive SBS, swell in a twin-screw extruder, and raise the temperature to 120°C for 2 hours to obtain Ultra-high molecular weight polyethylene spinning solution; the weight ratio of ultra-high molecular weight polyethylene resin to solvent is 1:70, and the weight ratio of ultra-high molecular weight polyethylene resin to functional additives is 100:1;

[0033] B, after spinning the ultra-high molecular weight polyethylene spinning solution obtained in step a and coagulating in a water bath, forming jelly filaments;

[0034] C, the jelly thread sliver that step b is obtained passes through guide roller, enters three-roll unit and five-roll unit step by step, ca...

Embodiment 2

[0036] An antistatic ultra-high molecular weight polyethylene fiber material used for packaging machinery guide rails is prepared by the following method:

[0037] a. Add ultra-high molecular weight polyethylene resin with a weight average molecular weight of 2 million to solvent mineral oil, add functional additive magnesium hydroxide, swell in a twin-screw extruder, and heat up to 80°C for 4 hours, Obtain ultra-high molecular weight polyethylene spinning solution; the weight ratio of ultra-high molecular weight polyethylene resin to solvent is 1:80, and the weight ratio of ultra-high molecular weight polyethylene resin to functional auxiliary agent is 100:2;

[0038] B, after spinning the ultra-high molecular weight polyethylene spinning solution obtained in step a and coagulating in a water bath, forming jelly filaments;

[0039] C, the jelly thread sliver that step b is obtained passes through guide roller, enters three-roll unit and five-roll unit step by step, carries ou...

Embodiment 3

[0041] An antistatic ultra-high molecular weight polyethylene fiber material used for packaging machinery guide rails is characterized in that it is prepared by the following method:

[0042] a. Add ultra-high molecular weight polyethylene resin with a weight average molecular weight of 3 million to the solvent xylene, add functional additives POE and magnesium hydroxide, swell in a twin-screw extruder, and heat up to 80°C for 2 hours , to obtain ultra-high molecular weight polyethylene spinning solution; the weight ratio of ultra-high molecular weight polyethylene resin and solvent is 1:90, and the weight ratio of ultra-high molecular weight polyethylene resin and functional auxiliary agent is 100:3;

[0043] B, after spinning the ultra-high molecular weight polyethylene spinning solution obtained in step a and coagulating in a water bath, forming jelly filaments;

[0044] C, the jelly thread sliver that step b is obtained passes through guide roller, enters three-roll unit a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com