Compound flexible conductive fabric, preparation method of conductive fabric and flexible sensor of conductive fabric

A flexible conductive and flexible fabric technology, which is applied in the field of flexible mechanical sensors, composite flexible conductive fabrics, and flexible conductive fabric preparation, can solve problems such as damage and low toughness, and achieve the effects of simple process, enhanced conductivity, and easy distinction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

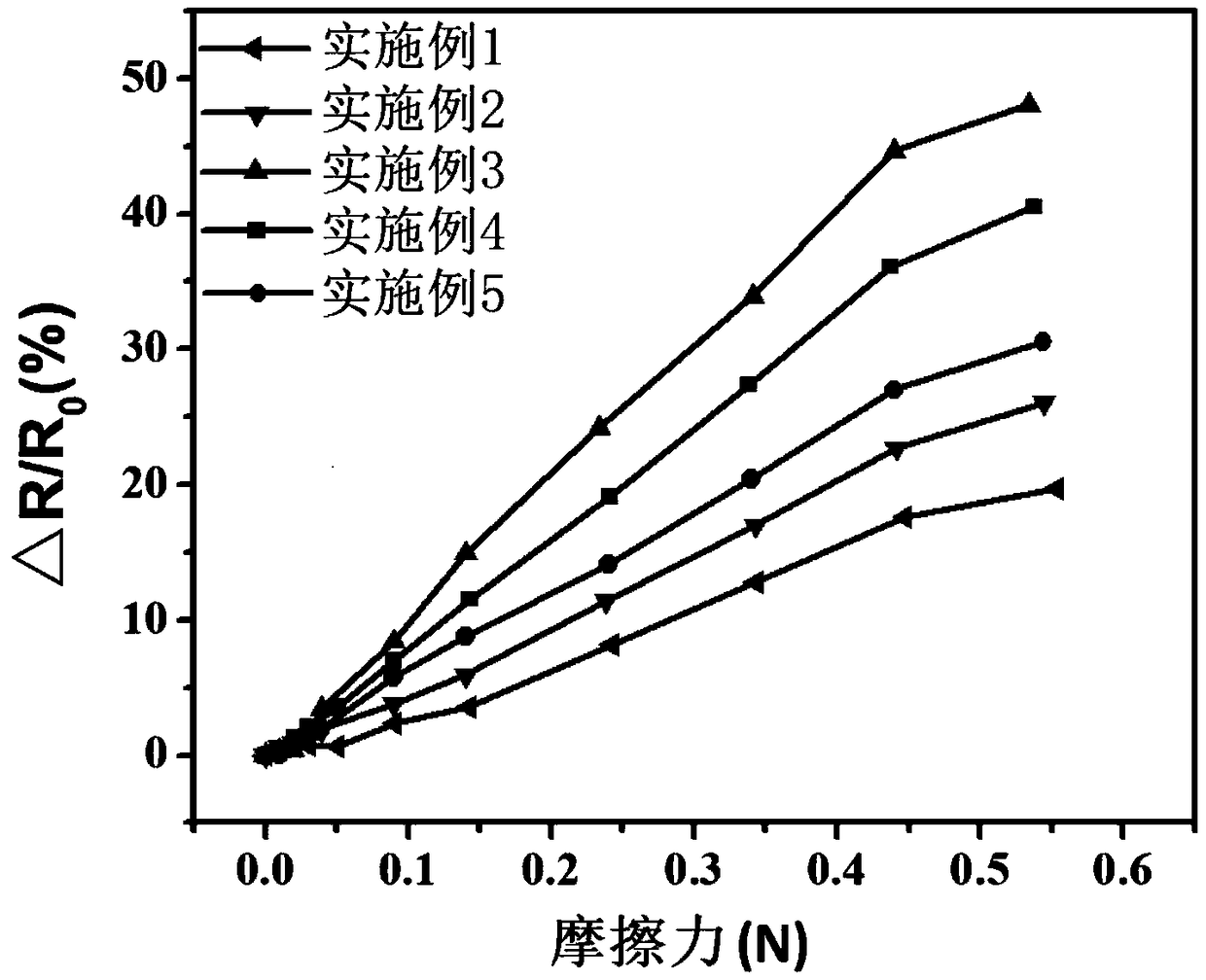

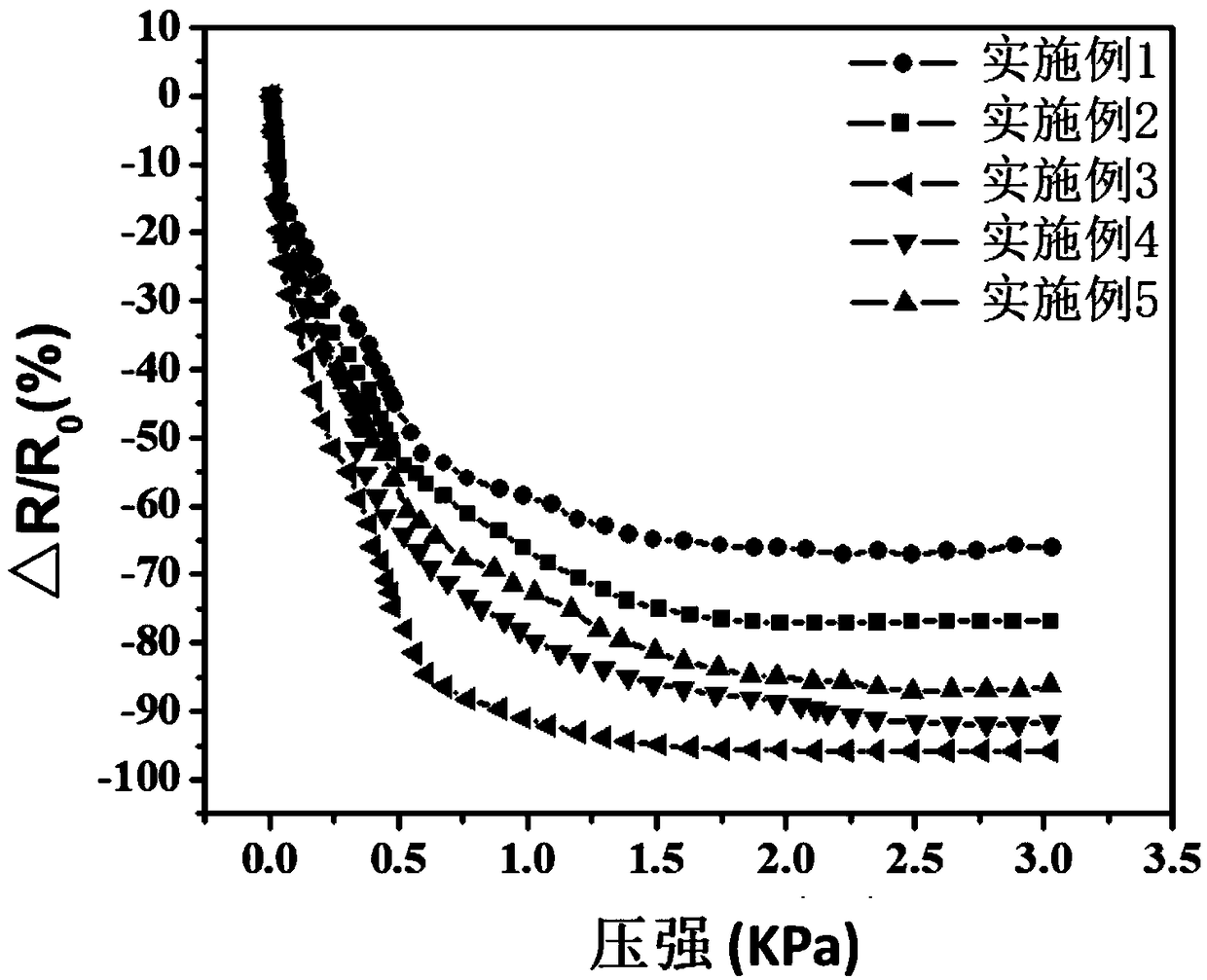

Embodiment 1

[0031] A kind of composite flexible conductive fabric, its preparation method comprises the following steps:

[0032] (1) Get 0.2g multi-walled carbon nanotubes;

[0033] (2) Place it in 40ml of DMF solvent, successively shear and stir for 30min, and ultrasonically disperse for 1h to obtain a uniformly dispersed carbon nanotube dispersion;

[0034] (3) Soak the cyanoacrylate non-woven fabric in the carbon nanotube dispersion prepared in step (2), and then dry it for 5 minutes. The soaking is accompanied by ultrasonic treatment, and the drying temperature is 60°C. , and the drying time is 3 hours to obtain;

[0035] A flexible mechanical sensor comprises the composite flexible conductive fabric prepared above.

Embodiment 2

[0037] (1) Get 0.8g multi-walled carbon nanotubes;

[0038] (2) placing it in 40ml of ethanol solvent, followed by shearing and stirring for 30min, and ultrasonic dispersion for 1h to obtain a uniformly dispersed carbon nanotube dispersion;

[0039] (3) Soak the polyacrylonitrile non-woven fabric in the carbon nanotube dispersion prepared in step (2), and then dry it for 8 minutes. The soaking is accompanied by ultrasonic treatment, and the drying temperature is 80°C. Drying time is 3 hours, obtains;

[0040] A flexible mechanical sensor comprises the composite flexible conductive fabric prepared above.

Embodiment 3

[0042] (1) Get 1.4g multi-walled carbon nanotubes;

[0043] (2) Place it in 40ml of DMF solvent, successively shear and stir for 30min, and ultrasonically disperse for 1h to obtain a uniformly dispersed carbon nanotube dispersion;

[0044] (3) Soak the cyanoacrylate non-woven fabric in the carbon nanotube dispersion prepared in step (2), and then dry it for 10 minutes. The soaking is accompanied by ultrasonic treatment, and the drying temperature is 80°C. , and the drying time is 2 hours to obtain;

[0045] A flexible mechanical sensor comprises the composite flexible conductive fabric prepared above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com