Construction method of piled anchor and liquid nitrogen frozen earth wall combined support system

A composite support and construction method technology, applied in sheet pile wall, excavation, infrastructure engineering and other directions, can solve the problems of complicated construction, long formation time of frozen soil wall, low construction efficiency of support system, etc., and achieve support performance. Reliable, high bearing capacity and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

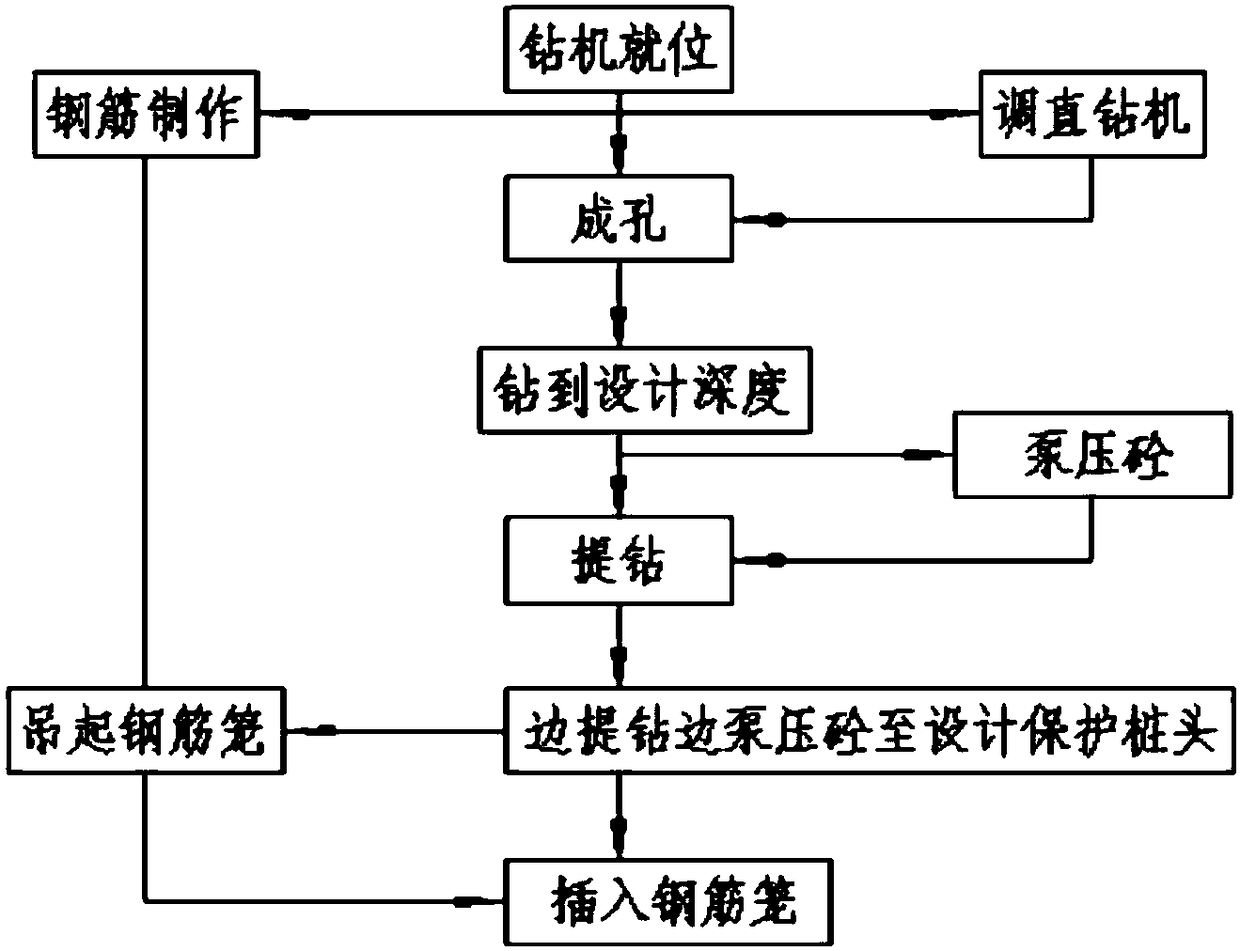

[0039] The construction method is as follows:

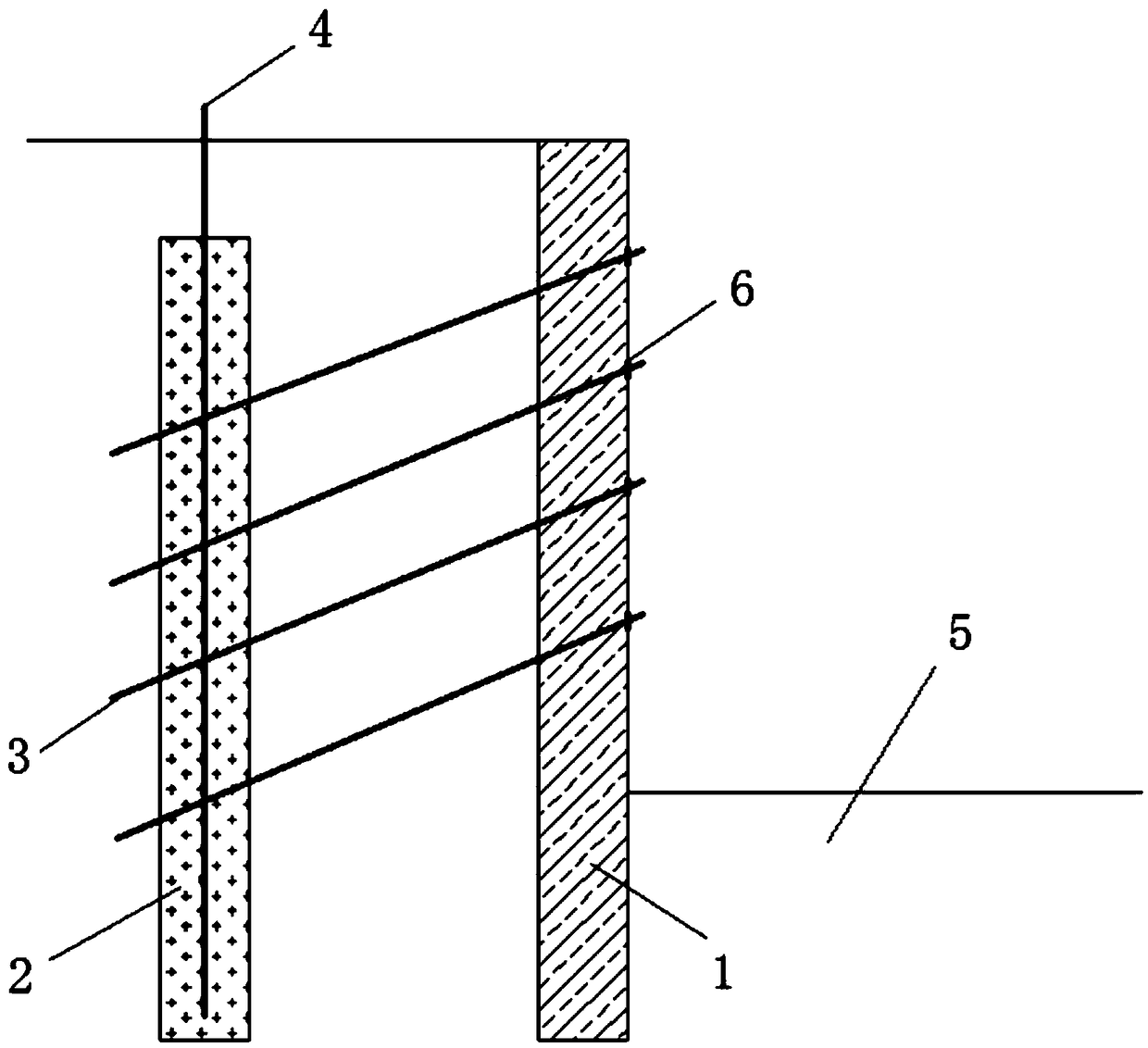

[0040] Step 1. Evenly arrange the slope protection piles 1 along the edge of the foundation pit 5. In this embodiment, the slope protection piles 1 are long spiral drilled cast-in-place piles. The specific process is as follows:

[0041] (1) Hole forming: use a long auger drilling rig for drilling construction, first straighten the drilling rig, and then stop after drilling to the design elevation with the drill pipe.

[0042] (2) Pumped concrete: pump concrete with a slump of 220±20mm while lifting the drill until it reaches the orifice. When the pouring of concrete starts, the driver of the drilling rig blows his whistle to give a signal. The person in charge of the pump truck starts to pump the concrete and responds by whistle to the driver of the drilling rig. The driver of the drilling rig starts to lift the drill after receiving a clear response. If there is not much concrete stored in the ground pump during the pouring pr...

Embodiment 2

[0071] The difference between this embodiment and Embodiment 1 is that in step (2) of step 3, the liquid nitrogen supply pipeline adopts pipelines of different materials. The freezing tube 4 is made of Ф108×8mm low-temperature resistant plastic pipe, the temperature measuring tube is made of Ф89×5mm low-temperature resistant plastic pipe, the liquid supply pipe and the system connecting pipe are made of Ф32×3.0mm R304 low-temperature resistant plastic pipe, and the plastic material can be PVC, PPR, ABS , PE and other plastic materials. In this embodiment, there is no need to pull out the freezing tube 4 in step (4) of step 3. The steps of pulling out the frozen pipe 4 are reduced, the construction steps are reduced, and the efficiency is improved.

Embodiment 3

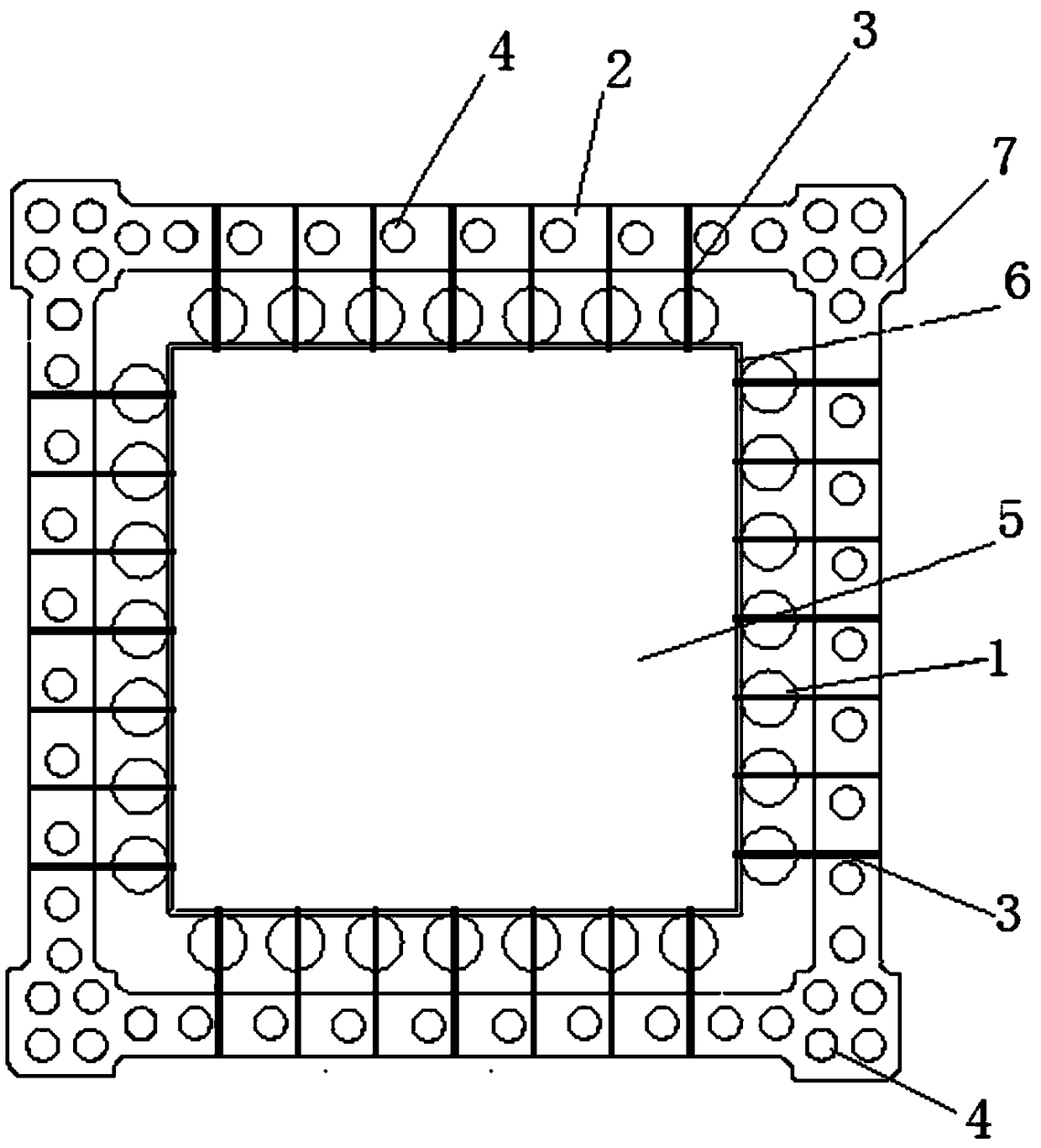

[0073] The difference between this embodiment and Embodiment 1 is that the shape of the liquid nitrogen frozen soil wall 2 is not an upright plane wall but a curved frozen soil wall, and the freezing pipe 4 in step 1 is arranged along a curve. The span of the curved frozen soil wall is small, and the rigidity of the end of the frozen soil wall and the overall stability of the frozen soil wall must be guaranteed. The frozen column pile 7 needs to bear the thrust transmitted by the curved frozen soil wall and the pressure of the soil within the pile range. The tension side of the liquid nitrogen frozen soil wall 2 is also provided with steel bars, glass fiber bars or bamboo bars as tensile materials. Can adapt to the foundation pit 5 needs of more shapes like this.

[0074] Before the construction of the composite support system, the drainage system can be set first to avoid the impact of groundwater on the construction of the support system, and drainage structures such as surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com