Flue gas wet method desulfurized gypsum slurry on-line density and pH value combined measuring device and measuring method

A measuring device, wet desulfurization technology, applied in measuring devices, specific gravity measurement, instruments, etc., can solve the problems of inconvenient regular calibration, difficult and safe operation of desulfurization system, and shortening the service life of equipment, so as to reduce the measurement accuracy and realize the Separation of steam and water to ensure the effect of fluid state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

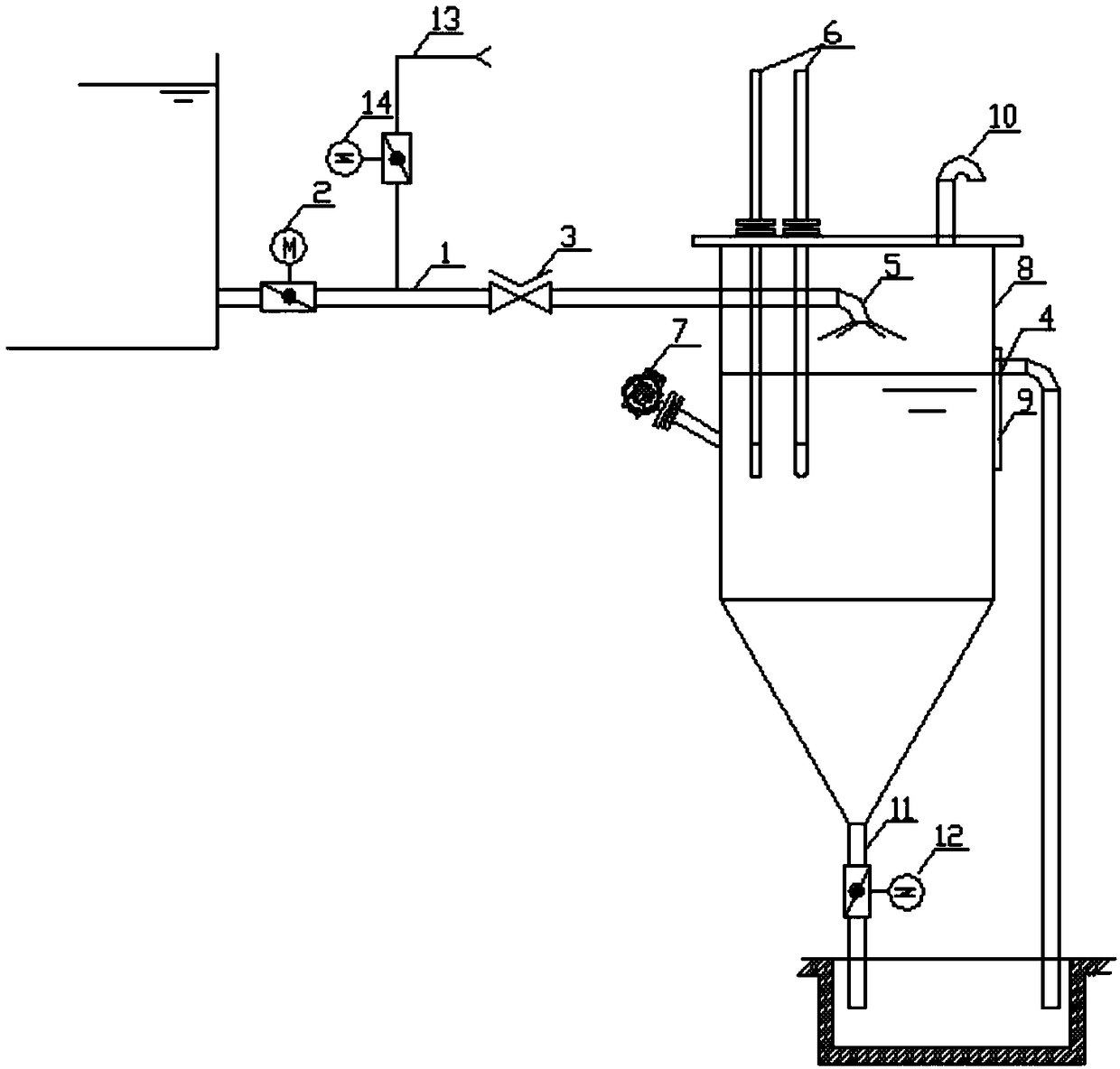

[0047] This embodiment provides a figure 1 The flue gas wet desulfurization gypsum slurry density and pH value online joint measurement device with the structure shown includes a sampling pipeline 1, a sampling electric butterfly valve 2, a sampling manual adjustment diaphragm valve 3, an overflow port 4, a sprinkler head 5, and a pH meter 6. Density meter 7, measuring box 8, liquid level observation window 9, vent hole 10, pulp discharge port 11, pulp discharge electric butterfly valve 12, water flushing pipeline 13, water flushing electric butterfly valve 14, flushing water inlet ( figure 1 Not marked), overflow pipe ( figure 1 not marked) and discharge pipeline ( figure 1 not marked). Wherein, the connection relationship, optional materials and functions of each component have been introduced above, and will not be repeated here.

[0048] In this embodiment, the shower head 5 is a solid cone nozzle with an inlet pressure of 0.5 bar, a port size of 1-1 / 2, and a spray angl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com