Ampelopsis grossedentata yoghurt and production method thereof

A production method and technology for rattan tea, applied in the field of beverage processing, can solve the problems of poor health care effect, uneven color, strong bitterness and astringency, etc., and achieve the effects of rich nutritional value, uniform color and less taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

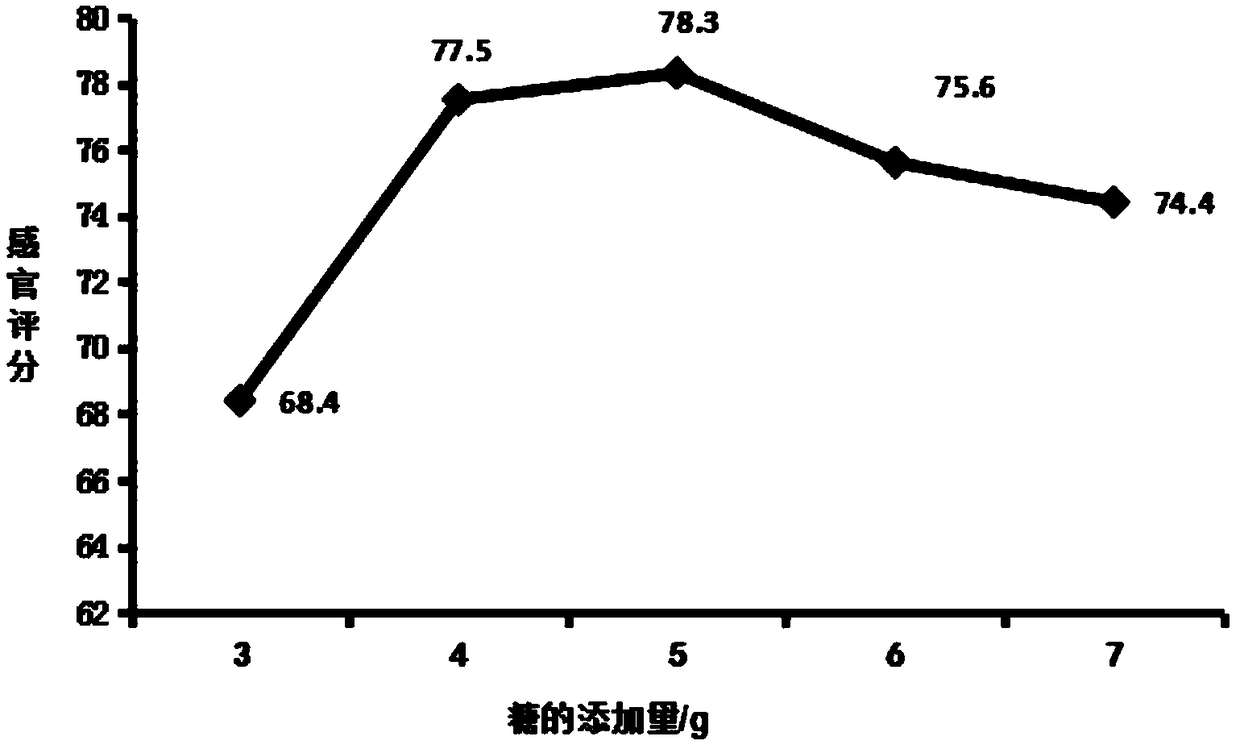

[0025] Embodiment 1: a kind of vine tea yogurt, comprises vine tea, milk, white granulated sugar and lactic acid bacteria, its ratio by weight: vine tea 1g, white granulated sugar 3g, milk 50g and lactic acid bacteria 0.5g, its preparation method comprises the following steps:

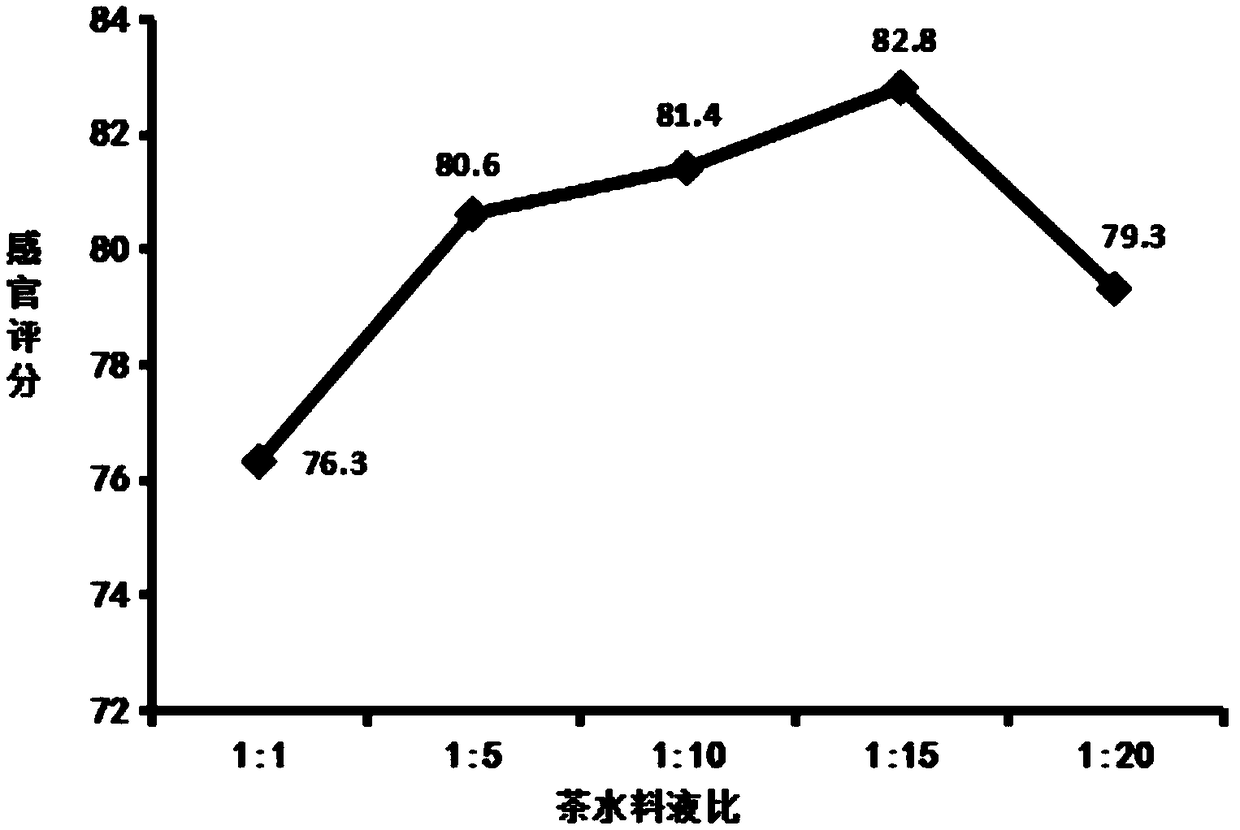

[0026] (1) Preparation of rattan tea liquid: mix the roasted rattan tea leaves with water at a ratio of 1:10 (g / ml), extract in a constant temperature water bath at 60-85°C for 50-75min, filter and set aside;

[0027] (2) Raw material blending: Pour the prepared tea liquid into the proportioned milk, add the proportioned white sugar, and homogenize for 5-10 minutes;

[0028] (3) Sterilization: Sterilize at 70-90°C for 10-30 minutes;

[0029] (4) Cooling: cooling at room temperature for 5-10 minutes;

[0030] (5) Inoculation: Inoculate lactic acid bacteria into the raw materials prepared after cooling according to 1% inoculum amount;

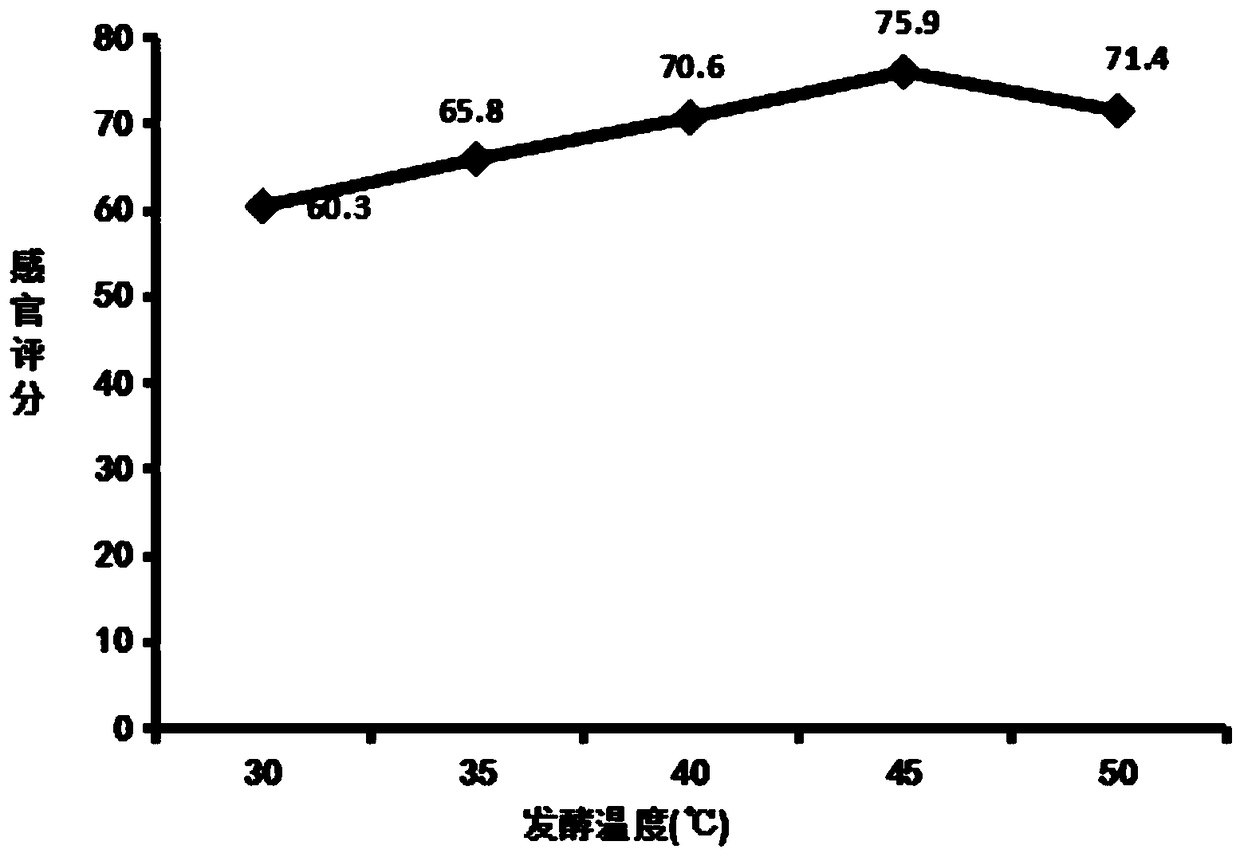

[0031] (6) Fermentation: ferment in a constant temperature ferment...

Embodiment 2

[0034] Embodiment 2: a kind of vine tea yogurt, comprises vine tea, milk, white granulated sugar and lactic acid bacteria, its ratio by weight: vine tea 2g, white granulated sugar 7g, milk 200g and lactic acid bacteria 2.5g, and its preparation method comprises the following steps:

[0035] (1) Preparation of vine tea liquid: mix the roasted vine tea leaves with water at a ratio of 1:20 (g / ml), extract in a constant temperature water bath at 60-85°C for 50-75min, filter and set aside;

[0036] (2) Raw material blending: Pour the prepared tea liquid into the proportioned milk, add the proportioned white sugar, and homogenize for 5-10 minutes;

[0037] (3) Sterilization: Sterilize at 70-90°C for 10-30 minutes;

[0038] (4) Cooling: cooling at room temperature for 5-10 minutes;

[0039] (5) Inoculation: Inoculate lactic acid bacteria into the raw materials prepared after cooling according to 1% inoculum amount;

[0040] (6) Fermentation: ferment in a constant temperature fermen...

Embodiment 3

[0043] Embodiment 3: a kind of vine tea yogurt, comprises vine tea, milk, white granulated sugar and lactic acid bacteria, its ratio by weight: vine tea 1.5g, white granulated sugar 5g, milk 125g and lactic acid bacteria 1.5g, and its preparation method comprises the following steps:

[0044] (1) Preparation of vine tea liquid: mix the roasted vine tea leaves with water at a ratio of 1:15 (g / ml), extract in a constant temperature water bath at 60-85°C for 50-75min, filter and set aside;

[0045] (2) Raw material blending: Pour the prepared tea liquid into the proportioned milk, add the proportioned white sugar, and homogenize for 5-10 minutes;

[0046] (3) Sterilization: Sterilize at 70-90°C for 10-30 minutes;

[0047] (4) Cooling: cooling at room temperature for 5-10 minutes;

[0048] (5) Inoculation: Inoculate lactic acid bacteria into the raw materials prepared after cooling according to 1% inoculum amount;

[0049] (6) Fermentation: ferment in a constant temperature ferm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com