Composite liquid die forging device and method for bottom shell workblank of electric vehicle battery

A technology for electric vehicles and liquid die forging, which is applied in the field of electric vehicle battery bottom case forging. It can solve problems such as unstable welding quality, easy deformation of wax molds, and limited feeding effect, so as to achieve less internal pores and inclusion defects, and no oxidation. And the effects of inclusion pollution and fine microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

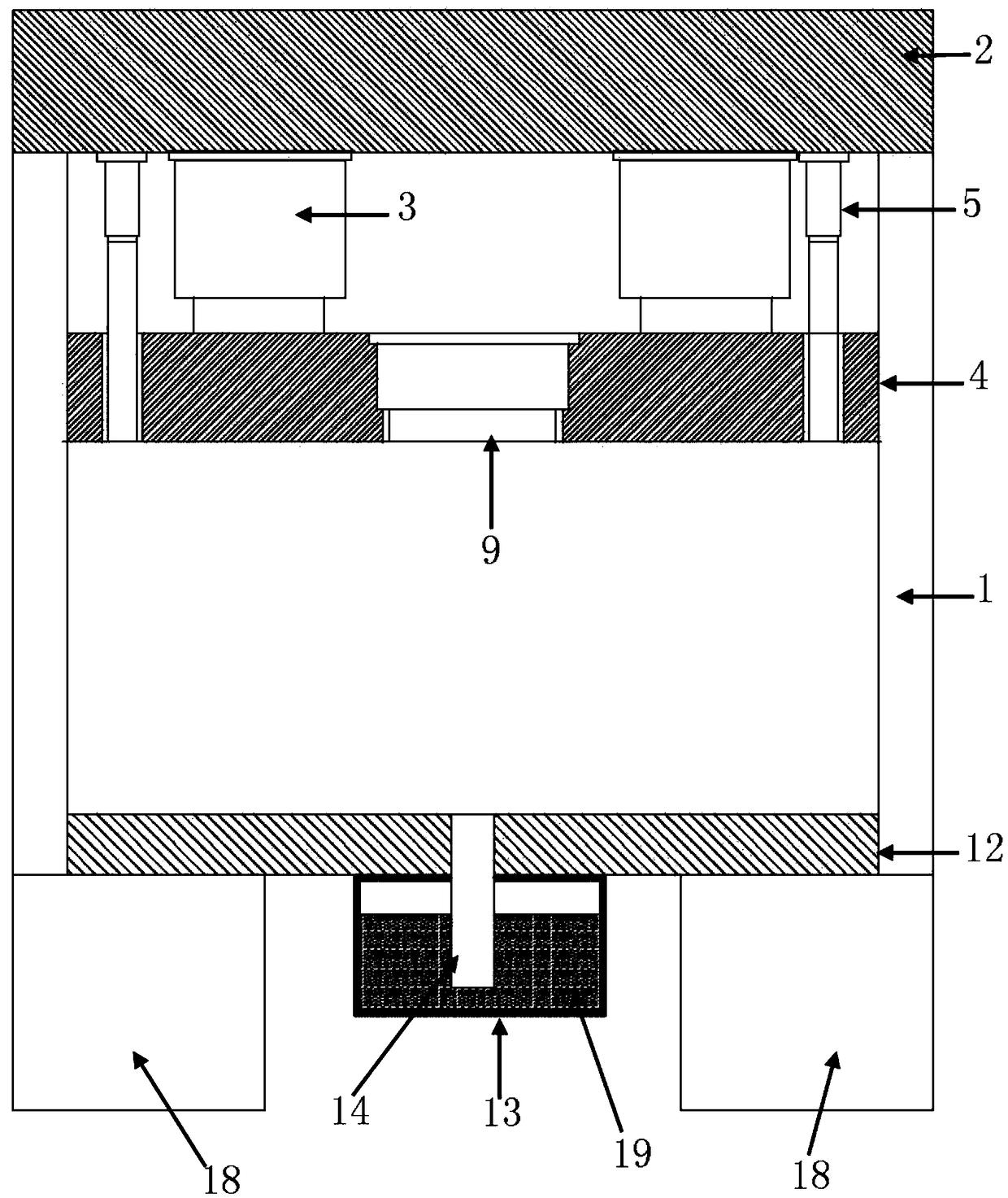

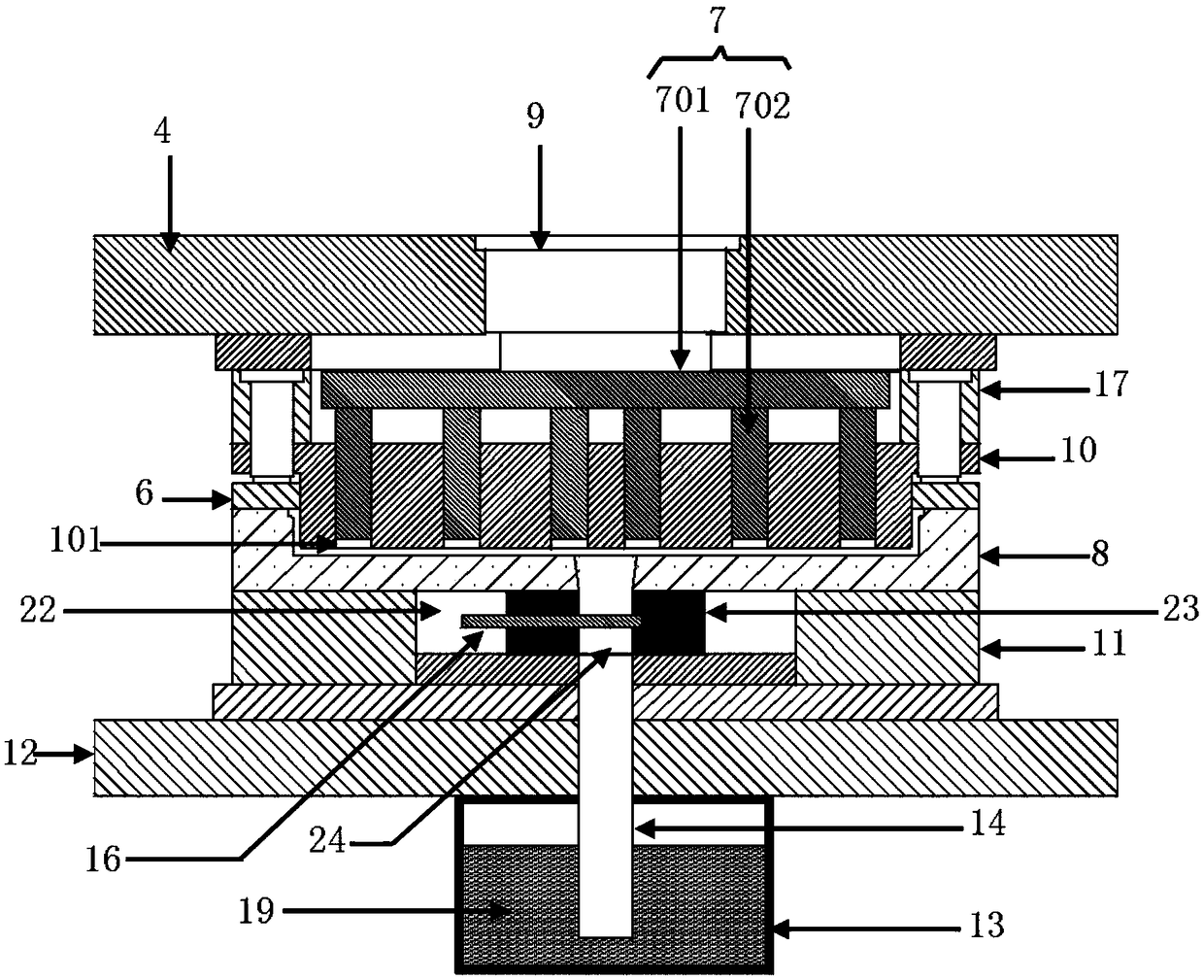

[0035] Such as Figure 1 to Figure 3 As shown, Embodiment 1 of the present invention provides a composite liquid forging device for the blank of the battery bottom case of an electric vehicle, including a frame 1, a top beam 2 is arranged above the frame 1, and the bottom of the top beam 2 is fixed A master cylinder 3 is connected, and a movable beam 4 is connected to the lower end of the master cylinder 3 .

[0036] The expansion and contraction of the main cylinder 3 can drive the movable crossbeam 4 to move up and down.

[0037]The periphery of the master cylinder 3 is provided with a mold clamping cylinder 5, the upper end of the mold clamping cylinder 5 is fixed on the top beam 2, and the piston rod of the mold clamping cylinder 5 passes through the movable beam 4 and is connected with a joint template6. The mold clamping cylinder 5 can drive the clamping plate 6 to move up and down.

[0038] The lower part of the movable beam 4 is connected with a main pressure head 1...

Embodiment 2

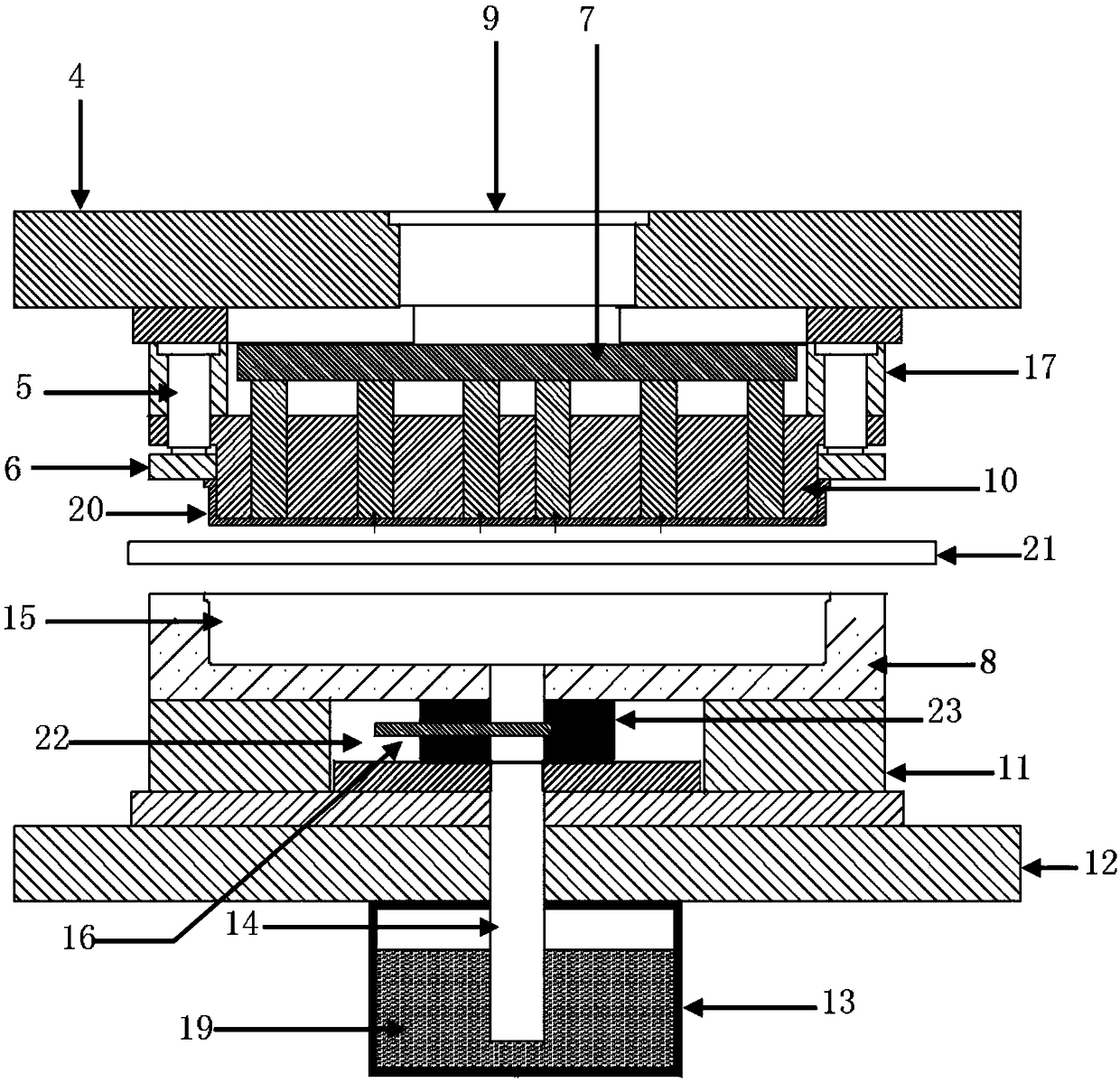

[0046] Such as Figure 2 to Figure 3 As shown, Embodiment 2 of the present invention provides a composite liquid die forging method for a blank of an electric vehicle battery bottom case, the method comprising the following steps:

[0047] Step S110: Clamping the mold: push the movable beam 4 downward through the main cylinder 3, so that the main pressure head 10 extends into the mold cavity 15 to reach the predetermined position, and the mold clamping cylinder 5 continues to move downward so that the clamping plate 6 is attached to the upper edge of the mold 8 and pressurized until the set pressure is still; the auxiliary pressure head 7 moves to the preset position under the drive of the feeding cylinder 9, and the horizontal inserting plate 16 in the connecting block 23 is pulled apart by the hydraulic cylinder;

[0048] Step S120: Mold filling: open the air valve of the holding furnace 13 to pressurize the aluminum alloy liquid 19 in the holding furnace 13, so that the alu...

Embodiment 3

[0058] Such as Figure 2 to Figure 3 As shown, the third embodiment of the present invention provides a composite liquid die forging device for the blank of the battery bottom case of an electric vehicle and a method for using the device for die forging.

[0059] The liquid forging position of the liquid die forging for the blank of the electric vehicle battery bottom case is the horizontal position, and the opening of the battery bottom case is upward; The head is pressurized from top to bottom to form a shell cavity, and the position of the boss is partially pressurized and fed.

[0060] The device used for the liquid die forging of the blank of the electric vehicle battery bottom case includes four parts: the holding furnace, the pick-up mechanism of the liquid die forging machine and the mold:

[0061] The alloy liquid in the holding furnace enters the mold cavity through the liquid riser under the pressure of 0.2-0.4MPa;

[0062] The liquid die forging machine is a hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com