Laser-assisted micromachining system and temperature control method thereof

A laser-assisted and micro-machining technology, applied in the field of micro-machining, can solve the problems of affecting the size, reducing the machining accuracy and yield of the workpiece, and large fluctuations, achieving the effects of not easy dimensional deformation, avoiding excessive temperature, and improving machining accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

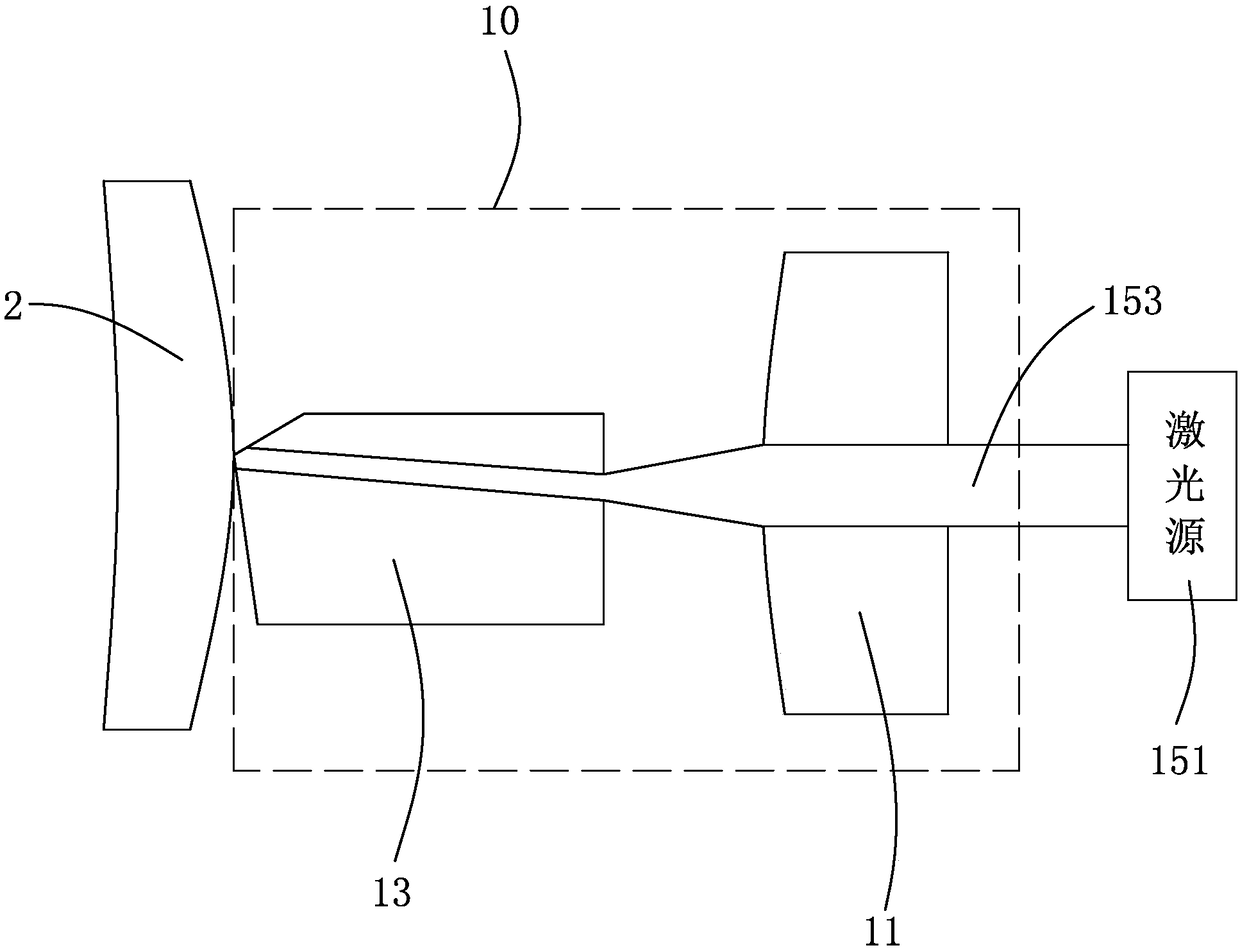

[0041] see figure 2 , is a schematic diagram of the principle of the laser-assisted micromachining system provided by the present invention. The laser-assisted micromachining system 10 cuts the workpiece 2 to be processed. The laser-assisted micromachining system 10 provides a laser beam to heat the workpiece 2 to be processed, and through reasonable control of the laser power, the size and speed of the spot pair, the laser beam generated by it is irradiated to the tool module 13 through focusing ( refer to Figure 5 ) of the front end, the workpiece 2 to be processed is irradiated and heated to change the mechanical properties of the material and reduce the cutting force.

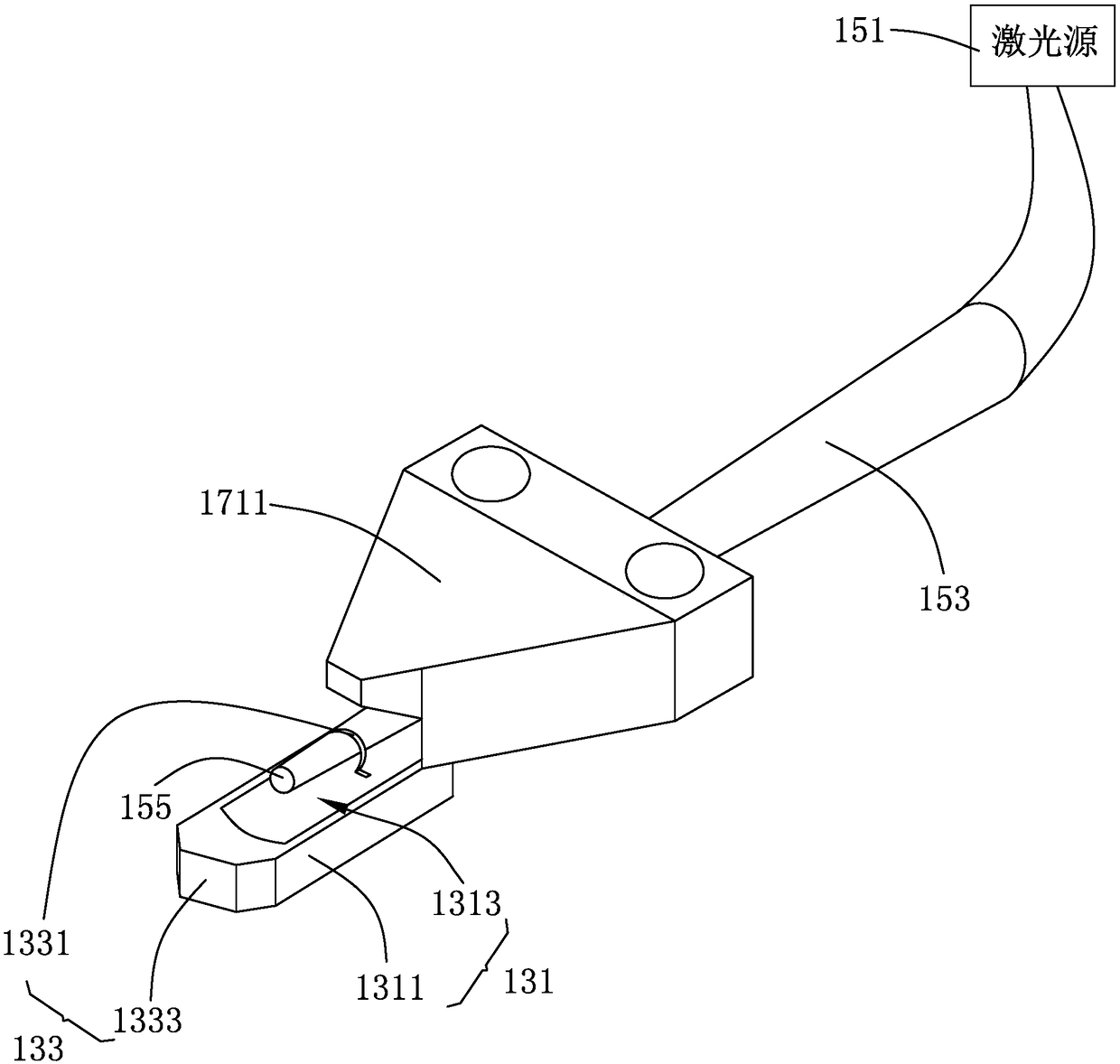

[0042] Please refer to image 3 and Figure 4 ,in image 3 It is a structural schematic diagram of the laser-assisted micromachining system of the present invention, Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com