Preparation method of polymercaptan curing agent

A polythiol and curing agent technology, which is applied in the direction of mercaptan preparation, ether preparation, and alkylene oxide preparation ether, etc. It can solve the problems of difficult reaction, difficulty in obtaining products with high thiol content, and difficult reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

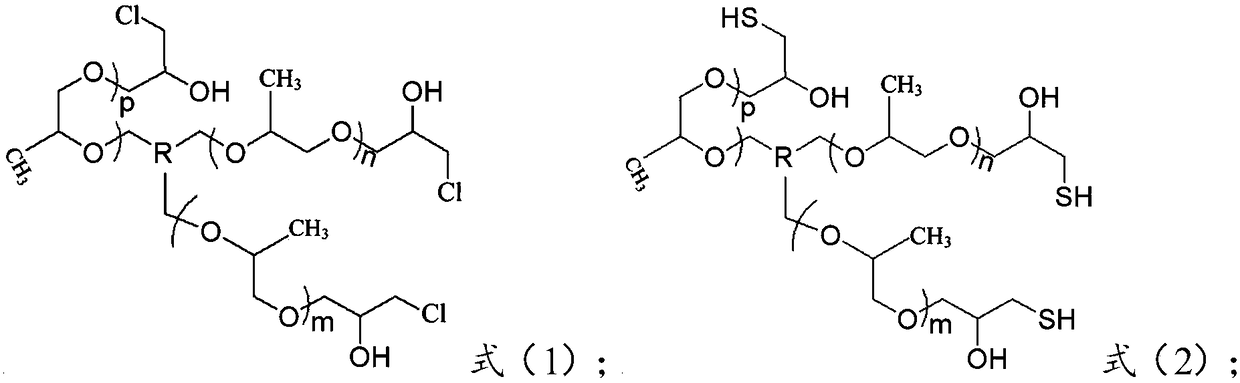

[0034] The invention provides a kind of preparation method of polythiol curing agent, it is characterized in that, comprises the following steps:

[0035] a) under the action of a phase transfer catalyst, reacting chlorinated polyether polyol shown in formula (1) with thiourea in an aqueous solution to obtain an intermediate;

[0036] b) carrying out alkaline hydrolysis reaction of the intermediate and an alkaline substance to generate polythiol shown in formula (2);

[0037]

[0038] Among them, R is selected from and one of

[0039] The degrees of polymerization p, m and n are each independently selected from 0 to 5, and p, m and n are not 0 at the same time;

[0040] The phase transfer catalyst is selected from one or more of quaternary ammonium salt compounds and quaternary phosphonium salt compounds.

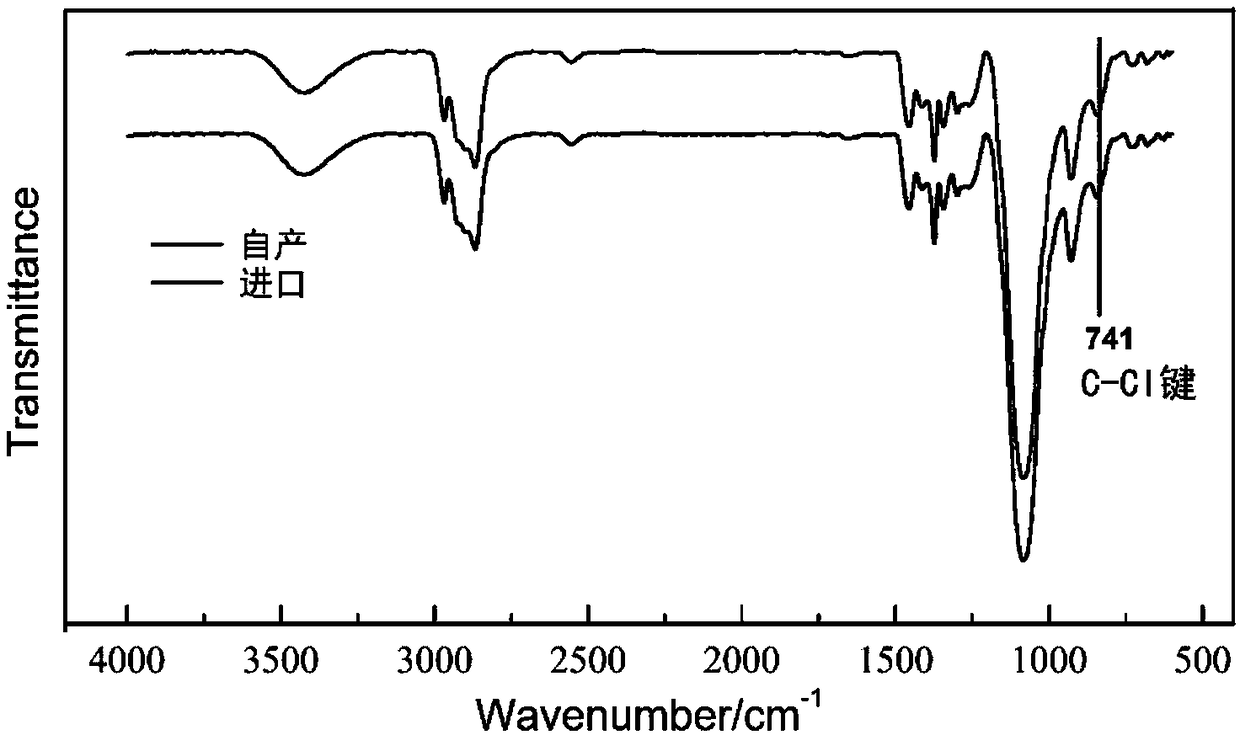

[0041] In the preparation method provided by the present invention, the chlorinated polyether polyol shown in formula (1) is reacted with thiourea in water under t...

Embodiment 1

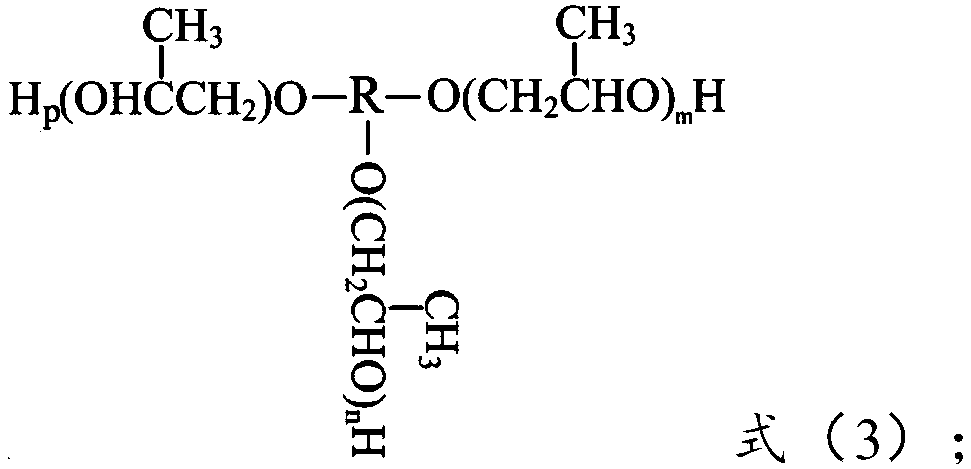

[0073] Add 40.00g (0.159mol hydroxyl) compound of formula 3 (p=1, m=1, n=1, R is 1) and 4.8g boron trifluoride to a 100mL four-necked flask equipped with a thermometer and a stirrer, and start Stir and heat to 70°C, slowly add 19.22g (0.207mol) of epichlorohydrin dropwise at 70°C, and keep warm at 70°C for 1 hour after the dropwise addition, to obtain 59.34g of a light yellow transparent intermediate having the structure of formula 1.

[0074] Continue to add 8.90g of tetrabutylammonium bisulfate and 80% thiourea aqueous solution (containing thiourea 20.26g, 0.269mol) to the system, and stir and react at 70°C for 3h; then add 123.08g of 25% thiourea Sodium carbonate solution (containing 0.290 mol of sodium carbonate), stirred and reacted at 70°C for 2h; cut out the upper oil phase, adjusted the pH value to 5-6 with dilute hydrochloric acid, then washed with 40.00g of 70°C deionized water, and then spun The water was distilled off to obtain a colorless and transparent polythiol...

Embodiment 2

[0077] Add 40.00g (0.159mol hydroxyl) compound of formula 3 (p=1, m=1, n=1, R is 1) and 4.8g boron trifluoride 5H to the 100mL four-neck flask equipped with thermometer and stirrer 2 O, start stirring and heat to 70°C, slowly add 17.74g (0.191mol) of epichlorohydrin dropwise at 70°C, keep warm at 70°C for 1h after the dropwise addition, and obtain a light yellow transparent intermediate with the structure of formula 1 57.86g.

[0078] Continue to add 8.68g tetrabutylammonium bisulfate and 80% thiourea aqueous solution (containing thiourea 18.86g, 0.248mol) to the system, stir and react at 70°C for 3h; then add 113.32g 25% thiourea Sodium carbonate solution (containing 0.267 mol of sodium carbonate), stirred and reacted at 70°C for 2h; cut out the upper oil phase, adjusted the pH value to 5-6 with dilute hydrochloric acid, then washed with 40.00g of 70°C deionized water, and then spun The water was distilled off to obtain a colorless and transparent polythiol.

[0079] Accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com