Paracoccus denitrificans strain with sulfur and ferrum co-substrate autotrophic denitrification function and culture method and application thereof

A denitrification paracoccus, autotrophic denitrification technology, applied in the denitrification paracoccus strain, the application field of wastewater denitrification treatment process, can solve problems such as pollution, achieve the effect of simple process, low cost and strong practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

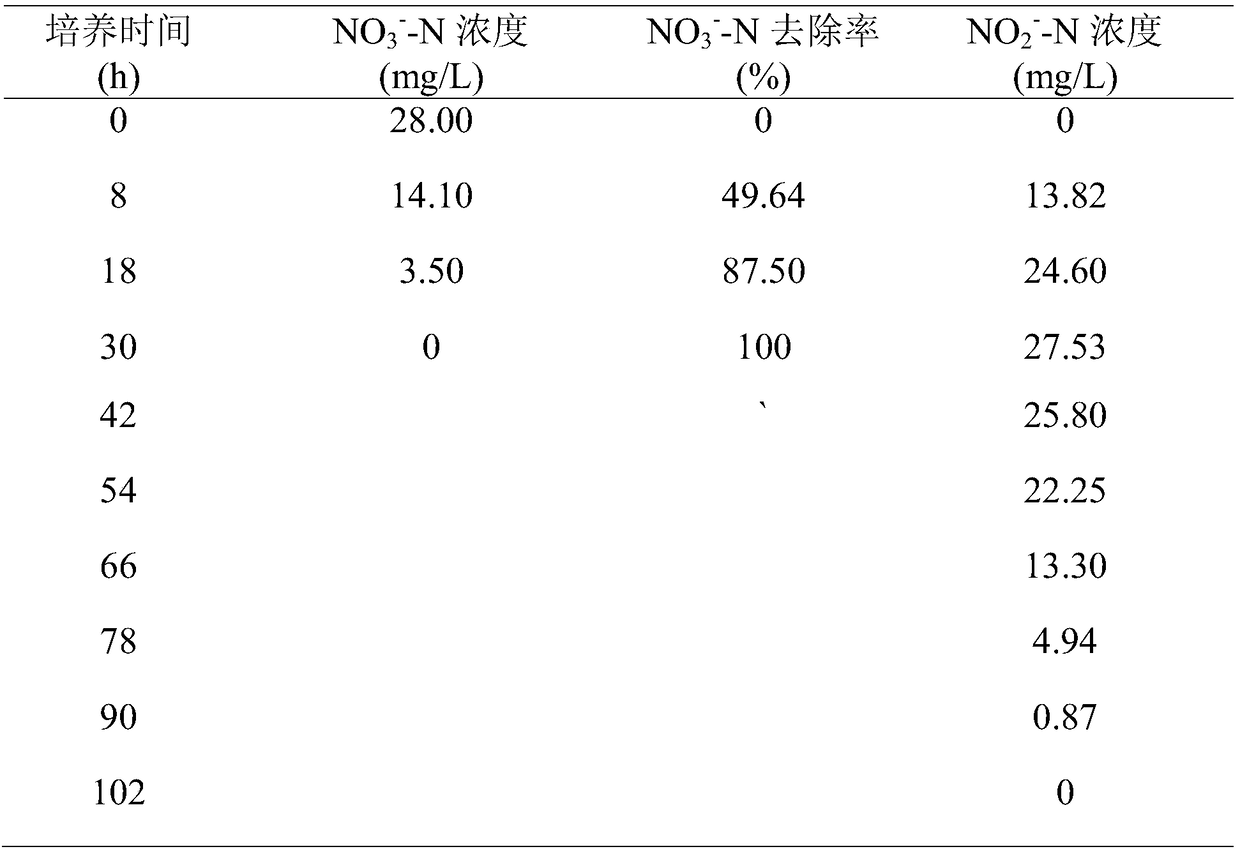

[0016] Embodiment 1: bacterial strain of the present invention removes nitrate in waste water with pyrite as electron donor under anaerobic conditions

[0017] Denitrification medium: KH 2 PO 4 14.7mmol / L, NaHCO 3 30mmol / L, NH 4 Cl 18.7mmol / L, MgCl 2 ·6H 2 O 3.25mmol / L, CaCl 2 2H 2 O 0.05mmol / L, pyrite 500mmol / L, adjust the pH to 7.0-7.2, and the medium is sterilized before use.

[0018] Using denitrification medium, inoculate the strain ZGL1 with a dry weight of 0.8g / L under anaerobic conditions, cultivate it at 30°C, and take samples at regular intervals to determine the changes in the concentration of nitrate and nitrite. The results are shown in Table 1. It can be seen from Table 1 that under anaerobic conditions, with pyrite as the electron donor, nitrate can be completely degraded, and after 30 hours of cultivation, 100% of the nitrate in the system was removed. Nitrite accumulated in the middle process and was completely converted into nitrogen after 102 hours...

Embodiment 2

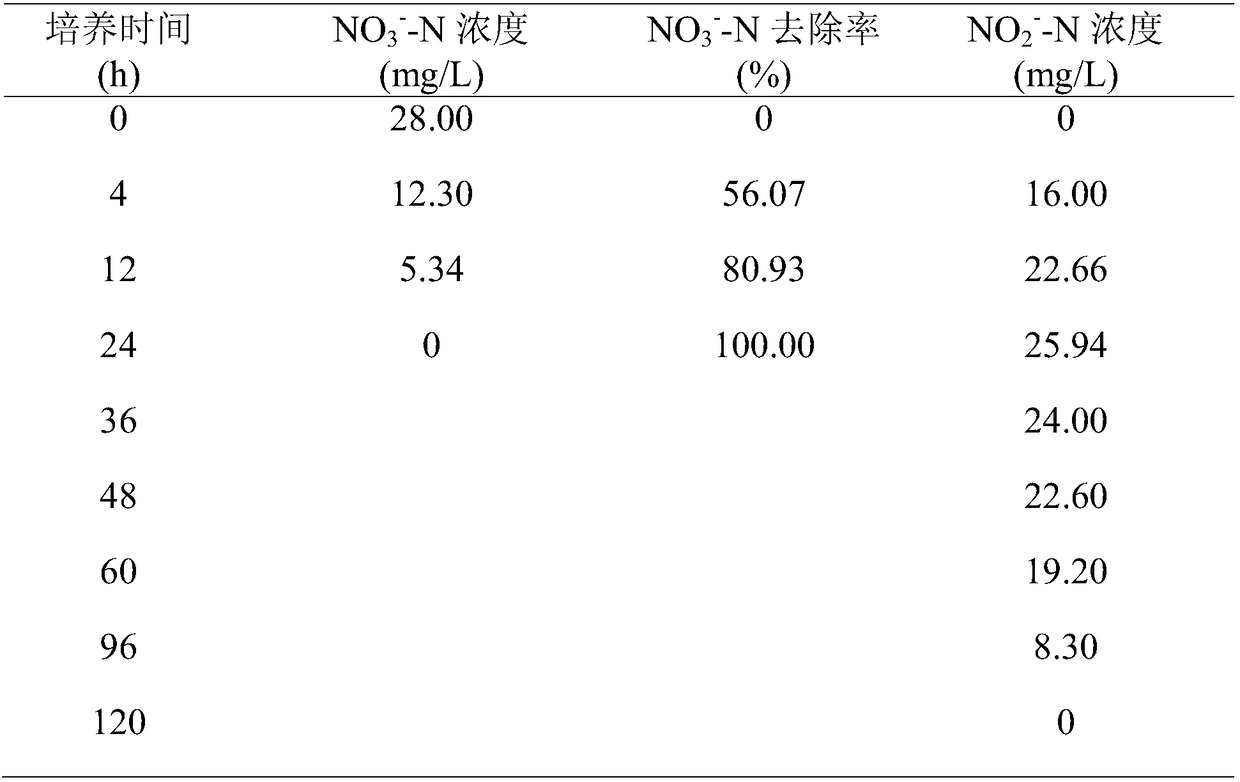

[0021] Embodiment 2: Bacteria of the present invention removes nitrate in waste water with ferrous sulfide as electron donor under anaerobic conditions

[0022] Denitrification medium: KH 2 PO 4 14.7mmol / L, NaHCO 3 30mmol / L, NH 4 Cl 18.7mmol / L, MgCl 2 ·6H 2 O 3.25mmol / L, CaCl 2 2H 2 O 0.05mmol / L, ferrous sulfide 500mmol / L, adjust the pH to 7.0~7.2, and the medium is sterilized before use

[0023] Using the denitrification medium, inoculate the strain ZGL1 with a dry weight of 0.8g / L under anaerobic conditions and cultivate it at 30°C. Samples were taken at regular intervals to determine the changes in the concentration of nitrate and nitrite. The results are shown in Table 2. It can be seen from Table 2 that under anaerobic conditions, with ferrous sulfide as the electron donor, nitrate can be completely degraded, and after 24 hours of cultivation, 100% of the nitrate in the system was removed. Nitrite is accumulated in the middle process, and it is completely conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com