High interlayer spacing artificial graphite material and preparation method thereof

An artificial graphite and spacing technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as limiting the application field and application effect of high-level spacing graphite materials, irregular interlayer structure, and acidic pH value. , to achieve the effect of mild processing technology, good electrical conductivity and high layer spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

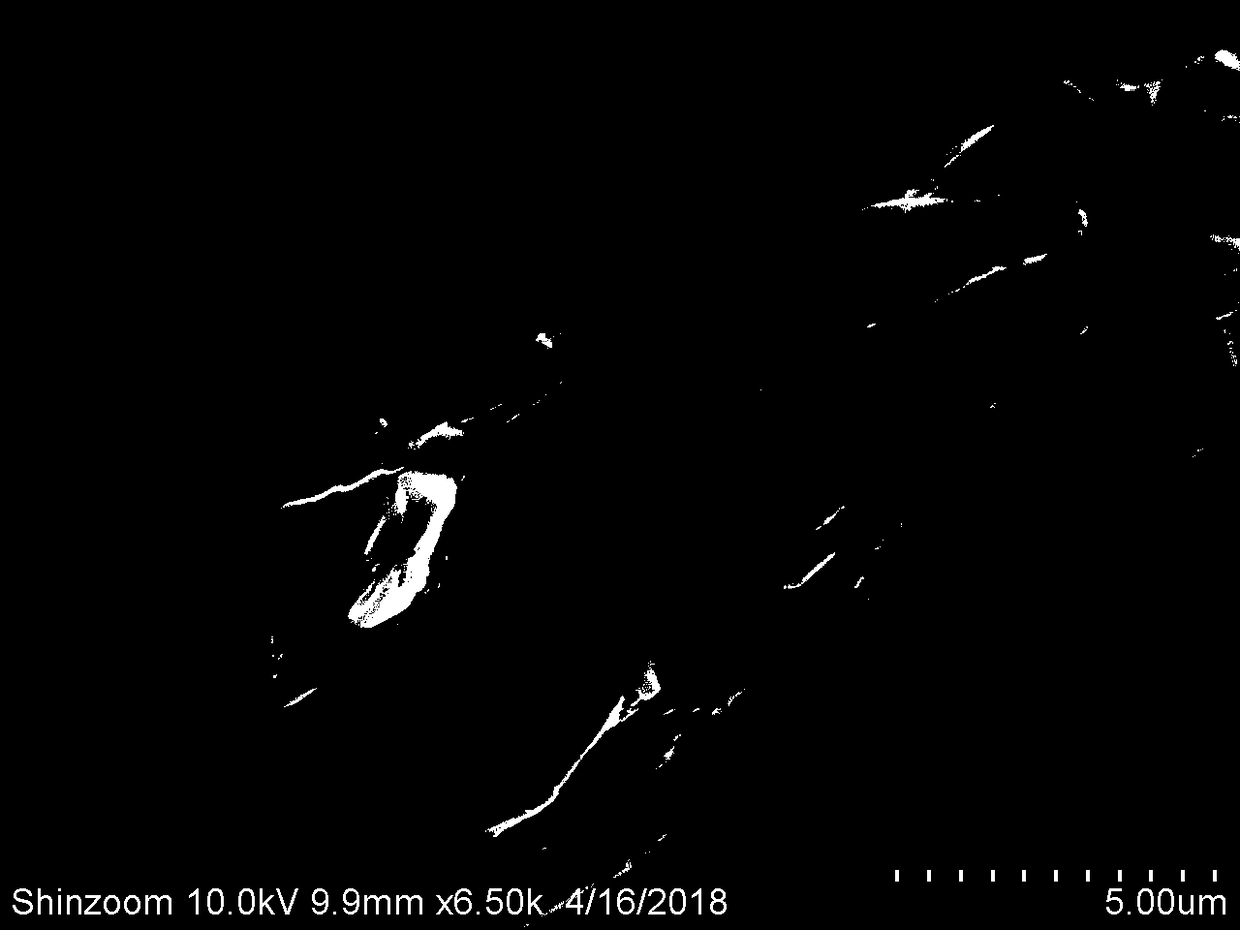

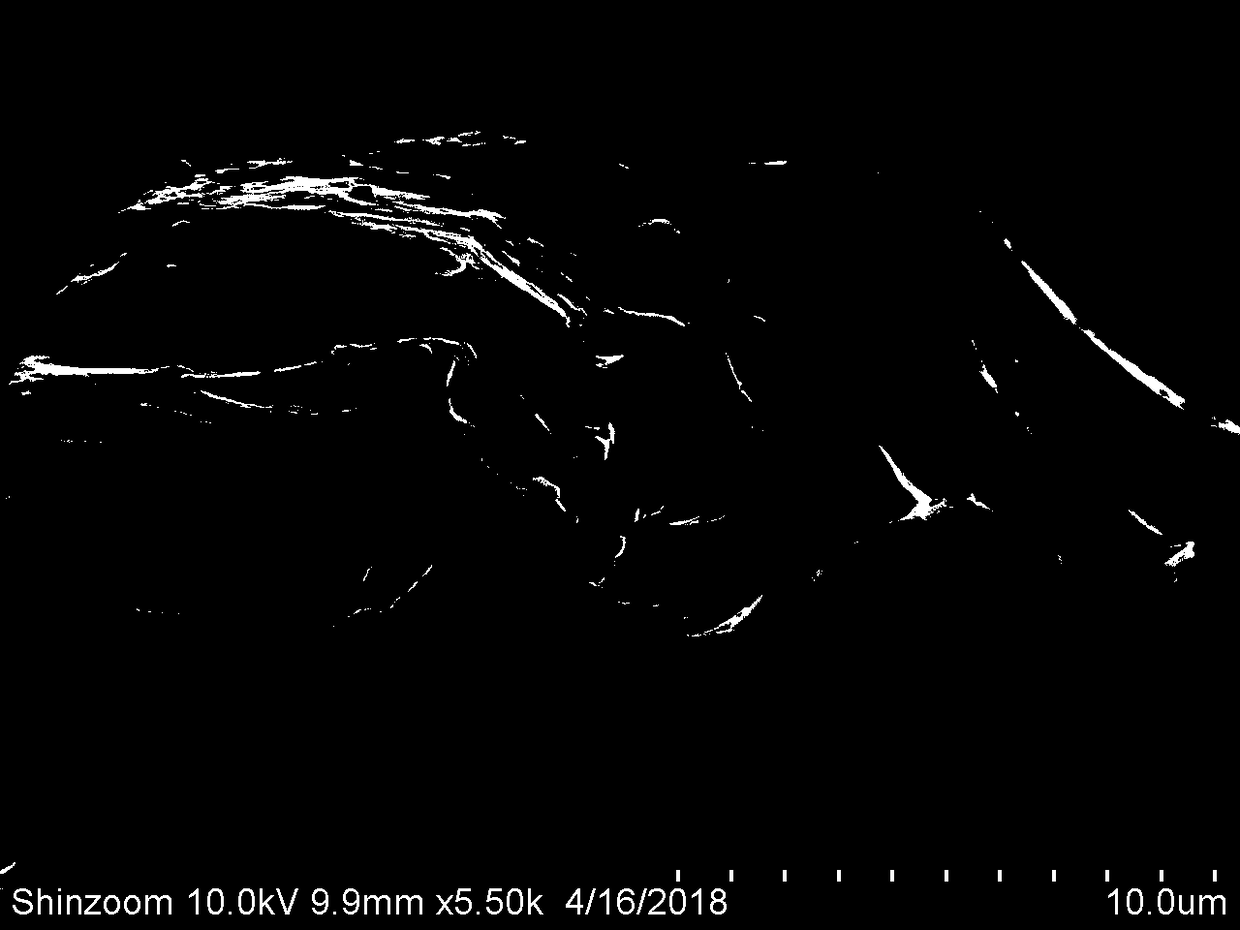

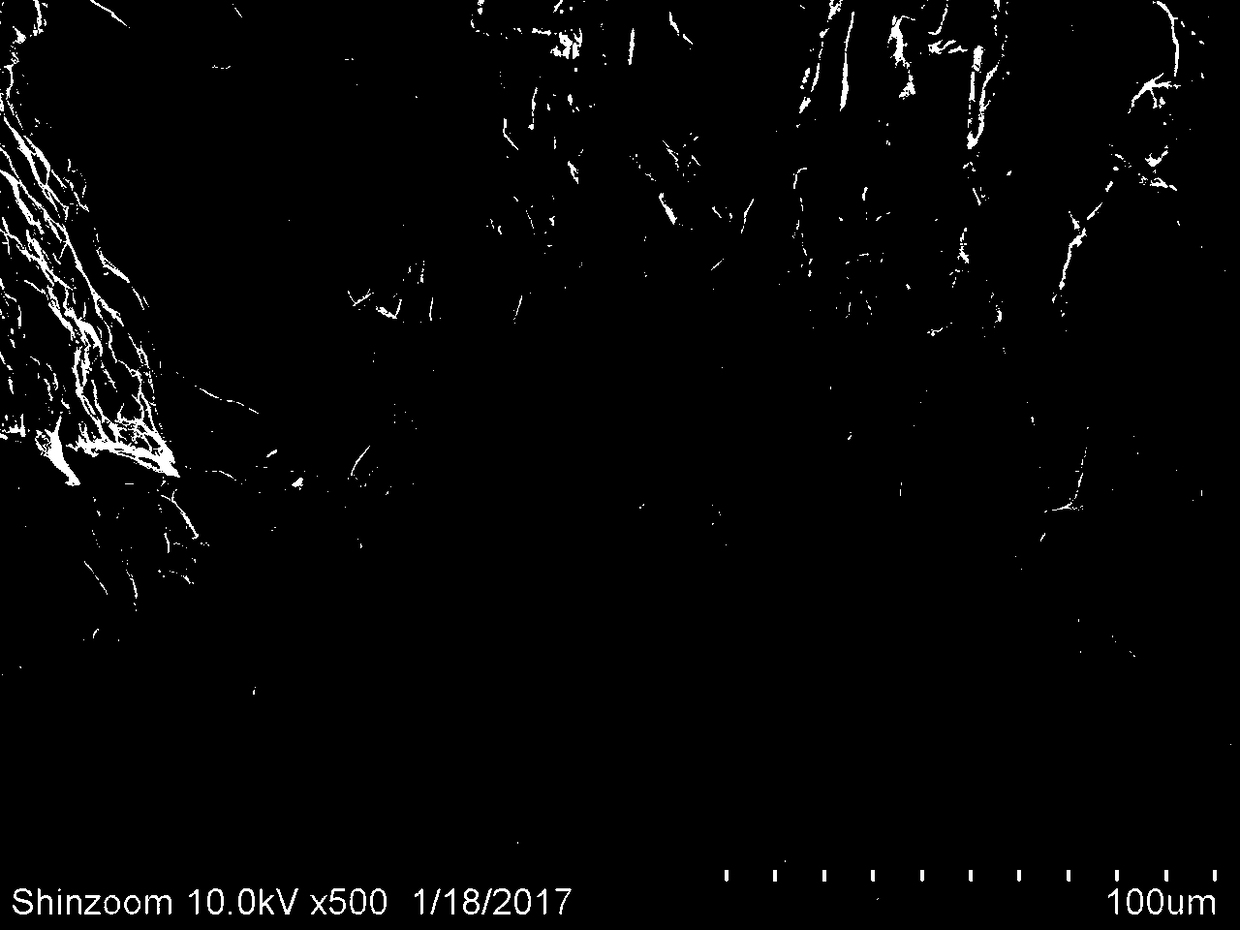

Image

Examples

Embodiment 1

[0028] The preparation method of 1# high-rise spacing artificial graphite material, the steps are as follows:

[0029] (I) Petroleum asphalt and biomass tar with a softening point of 90°C and D50=3.4 μm are used as raw materials, in which aromatic hydrocarbons in biomass tar account for 21%, phenols account for 45%, and the quality of asphalt and biomass tar The ratio is 5:1. Under the conditions of nitrogen atmosphere, 300rpm mechanical stirring, 400°C, 5atm, polycondensation and crosslinking were carried out for 12h to obtain crosslinked mesophase pitch.

[0030] (II) The cross-linked mesophase pitch was treated in a nitrogen atmosphere at a low temperature of 600°C for 5 hours, and the temperature was naturally cooled to room temperature to obtain green coke, which was then depolymerized by a multi-wheel mill.

[0031] (Ⅲ) The depolymerized green coke was heated up to 2600°C under a nitrogen atmosphere, kept for 1 hour to graphitize, and a high-layer spacing artificial gra...

Embodiment 2

[0033] The preparation method of 2# high-rise spacing artificial graphite material, the steps are as follows:

[0034] (I) Coal tar pitch and biomass tar with a softening point of 130°C and D50 = 4.1 μm are used as raw materials, in which aromatic hydrocarbons in biomass tar account for 32%, phenols account for 40%, and the quality of pitch and biomass tar The ratio is 10:3. Under the conditions of argon atmosphere, 300rpm mechanical stirring, 450°C and 16atm, polycondensation and crosslinking were carried out for 36h to obtain crosslinked mesophase pitch.

[0035] (II) The cross-linked mesophase pitch was treated in an argon atmosphere at a low temperature of 600°C for 3 hours, and the temperature was naturally cooled to room temperature to obtain green coke, which was then depolymerized by multiple round mills.

[0036] (Ⅲ) The depolymerized green coke was heated up to 3000°C in an argon atmosphere, kept for 2 hours for graphitization, and a high-layer spacing artificial gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com