Method for producing foamed ceramic building insulation material by using lithium tailings and steel slag tailings

A technology for foaming ceramics and building insulation, which is applied in the production and application of ceramic products and ceramic materials, can solve problems such as land occupation and environmental pollution, and achieve the effects of high production efficiency, simple preparation method and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

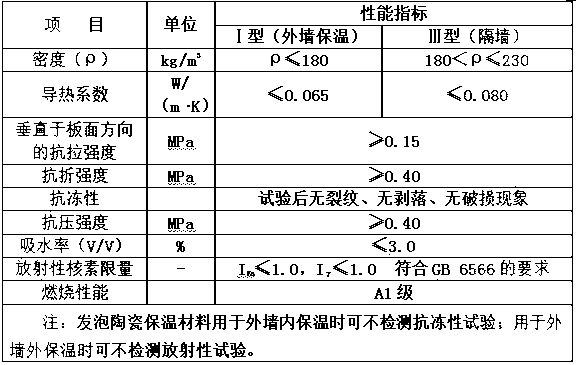

Image

Examples

Embodiment 1

[0036] A method of utilizing lithium tailings and steel slag tailings to produce foamed ceramic building insulation materials, said method comprising the following steps:

[0037] (1) Homogenization treatment of lithium tailings and steel slag tailings: First, homogenize the lithium tailings and steel slag tailings respectively. After homogenization, the steel slag tailings are crushed and passed through a 20-mesh sieve. After homogenization, the lithium tailings are passed through a 20-mesh sieve. ;

[0038] (2) Ingredients: Put 52kg of lithium tailings, 15kg of steel slag tailings, 23 kg of clay raw materials, 2kg of foam material A, and 42kg of water into a ball mill, mix and grind for 13 hours, and pass through a 60-mesh sieve to remove iron;

[0039] The main chemical composition of foam material A is: SiC: 20%, Fe 2 o 3 : 60%, MnO 2 : 12%;

[0040] (3) Preparation of foamed ceramic building insulation materials: put the ingredients after iron removal into the mud poo...

Embodiment 2

[0043] A method of utilizing lithium tailings and steel slag tailings to produce foamed ceramic building insulation materials, said method comprising the following steps:

[0044] (1) Homogenization treatment of lithium tailings and steel slag tailings: First, homogenize the lithium tailings and steel slag tailings respectively. After homogenization, the steel slag tailings are crushed and passed through a 20-mesh sieve. After homogenization, the lithium tailings are passed through a 20-mesh sieve. ;

[0045] (2) Ingredients: Put 57kg of lithium tailings, 27kg of steel slag tailings, 28kg of clay raw materials, 4kg of foam material A, and 46kg of water into a ball mill, mix and grind for 12 hours, and pass through a 60-mesh sieve to remove iron;

[0046] The main chemical composition of foam material A is: SiC: 45%, Fe 2 o 3 : 45%, MnO 2 :1%;

[0047] (3) Preparation of foamed ceramic building insulation materials: put the ingredients after iron removal into the mud pool, ...

Embodiment 3

[0050] A method of utilizing lithium tailings and steel slag tailings to produce foamed ceramic building insulation materials, said method comprising the following steps:

[0051] (1) Homogenization treatment of lithium tailings and steel slag tailings: First, homogenize the lithium tailings and steel slag tailings respectively. After homogenization, the steel slag tailings are crushed and passed through a 20-mesh sieve. After homogenization, the lithium tailings are passed through a 20-mesh sieve. ;

[0052] (2) Ingredients: Put 55kg of lithium tailings, 20kg of steel slag tailings, 25kg of clay raw materials, 3kg of foam material A, and 45kg of water into a ball mill, mix and grind for 14 hours, and pass through a 60-mesh sieve to remove iron;

[0053] The main chemical composition of foam material A is: SiC: 40%, Fe 2 o 3 : 52%, MnO 2 : 3%;

[0054] (3) Preparation of foamed ceramic building insulation materials: put the ingredients after iron removal into the mud pool,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com