Monascus pigment microcapsules and preparation method thereof

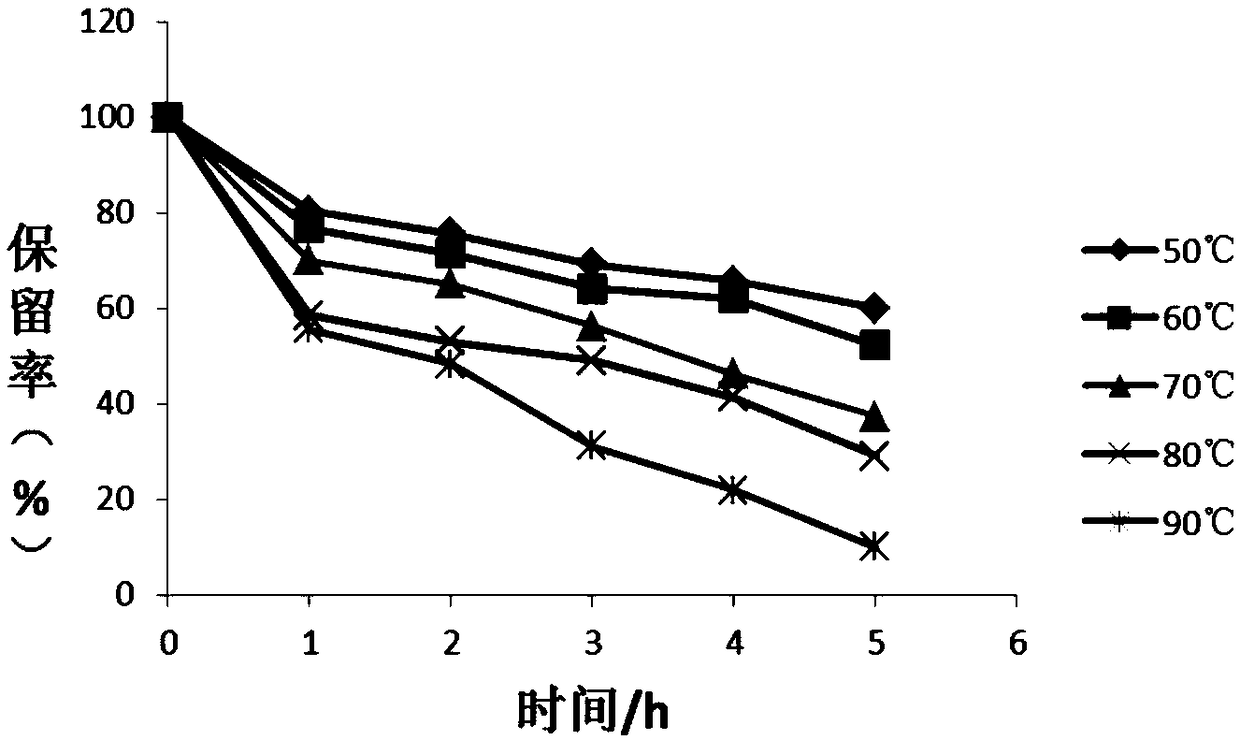

A technology of monascus pigment and microcapsules, applied in the field of capsule preparation, can solve the problems of easy decomposition and fading, unstable color price, etc., and achieve the effect of solving unstable color price, low price, and easy degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Add 30mg of Monascus pigment powder into 10mL of distilled water, stir to fully dissolve;

[0050] (2) Dissolve 0.3g of sodium alginate and 0.1g of calcium carbonate in 20mL of distilled water, and swell for 1 to 2 hours;

[0051] (3) fully mix the solution obtained in the above (1) and (2);

[0052] (4) Prepare soybean oil 90mL containing 1vt% Span 80;

[0053] (5) Fully mix the solutions obtained in the above (3) and (4), and fully stir with a magnetic stirrer at a speed of 600 rpm for emulsification to obtain a W / O emulsion;

[0054] (6) To the W / O emulsion obtained in (5), slowly add 340 μL of CH 3 20mL of soybean oil in COOH (reduce the pH value of the system), while fully stirring to make it evenly mixed, adding acid will cause Ca 2+ The dissociation of Ca 2+ In the emulsion droplets, it reacts with sodium alginate to form a uniform gel network structure, and wraps the red yeast pigment in the calcium alginate gel beads;

[0055] (7) Add 0.1M containing 0...

Embodiment 2

[0059] (1) Add 50 mg of Monascus pigment powder into 10 mL of distilled water, and stir to fully dissolve it;

[0060] (2) Dissolve 0.5g of sodium alginate and 0.5g of calcium carbonate in 20mL of distilled water, and swell for 1 to 2 hours;

[0061] (3) fully mix the solution obtained in the above (1) and (2);

[0062] (4) Prepare soybean oil 90mL containing 1.2vt% Span80;

[0063] (5) Fully mix the solutions obtained in the above (3) and (4), and fully stir with a magnetic stirrer at a speed of 1000 rpm to emulsify to obtain a W / O emulsion;

[0064] (6) To the W / O emulsion obtained in (5), slowly add 457 μL of CH 3 20mL of soybean oil in COOH (reduce the pH value of the system), while fully stirring to make it evenly mixed, adding acid will cause Ca 2+ The dissociation of Ca 2+ In the emulsion droplets, it reacts with sodium alginate to form a uniform gel network structure, and wraps the red yeast pigment in the calcium alginate gel beads;

[0065] (7) Add 0.1M containi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com