Composite nanofiltration membrane adopting tannic acid-titanium as isolation layer and preparation method of composite nanofiltration membrane

A composite nanofiltration membrane and tannic acid technology, applied in semi-permeable membrane separation, chemical instruments and methods, membranes, etc., can solve the problems of environmental and biological harm, low membrane permeability, high operating pressure, etc. Friendly, stable surface structure, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The embodiment of the present invention proposes a preparation method of a composite nanofiltration membrane using tannic acid-titanium as a separation layer, comprising the following steps:

[0015] S1, immersing the basement membrane in an aqueous solution containing tannic acid;

[0016] S2, adding a metal titanium salt to in-situ generate a tannic acid-titanium cross-linked functional surface layer on the base membrane to obtain a composite nanofiltration membrane.

[0017] Further, in a preferred embodiment of the present invention, the base membrane is selected from one of polysulfone porous membrane, polyethersulfone porous membrane, polyacrylonitrile porous membrane and polyvinylidene fluoride porous membrane. The adhesiveness of the functional groups of tannic acid makes it suitable for a variety of basement membranes.

[0018] Further, in a preferred embodiment of the present invention, the concentration of tannic acid in the aqueous tannic acid solution is 0...

Embodiment 1

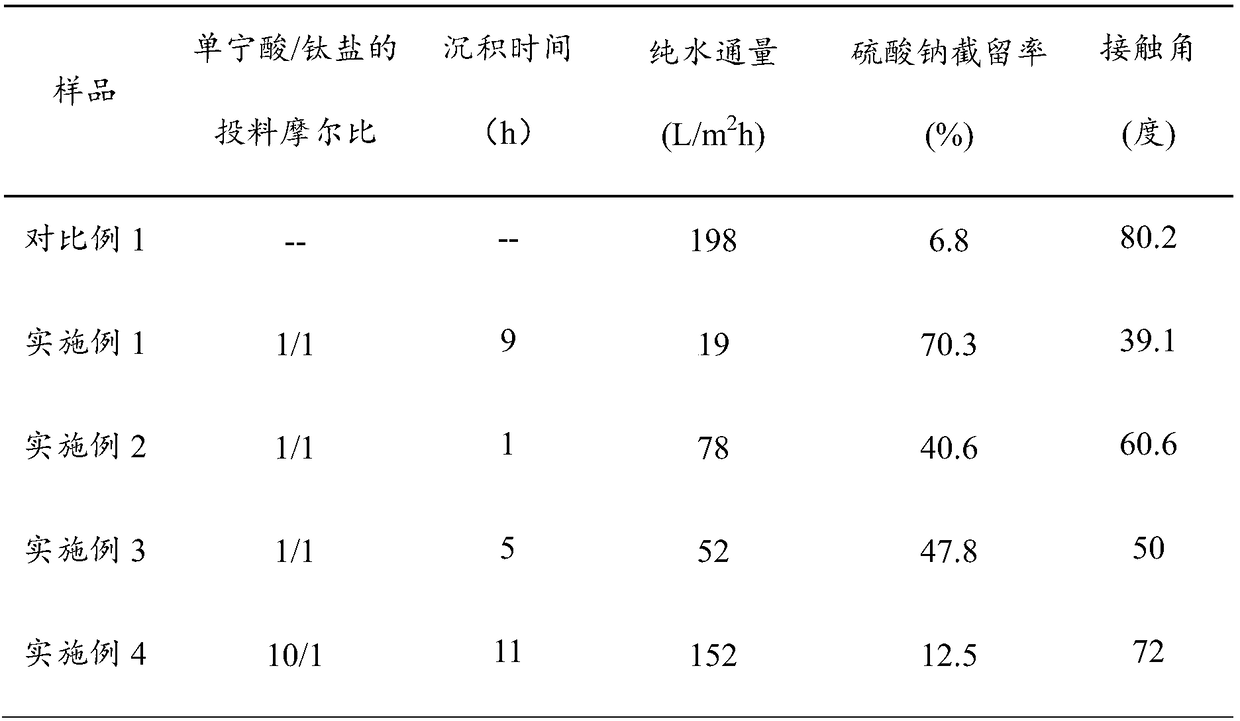

[0025] First, the polysulfone-based membrane is directly immersed in an aqueous solution containing 10.5mmol / L tannic acid; 10.5mmol / L titanium tetrachloride is added (that is, the molar ratio of tannic acid / titanium salt is 1 / 1), and the reaction is carried out at room temperature. After 9 hours, the tannic acid-titanium functional surface layer was finally deposited in situ on the polysulfone base membrane to obtain a composite nanofiltration membrane. After rinsing several times with deionized water, the prepared composite membrane was kept in water.

Embodiment 2

[0027] Example 2 is basically the same as Example 1, except that the reaction time is 1 h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com