Preparation method of oxidation catalyst used for diesel vehicle

A catalyst and oxidation-type technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of the limitation of the amount of precious metals, and achieve good resistance to sulfur toxicity, Reduces PM emissions and has good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

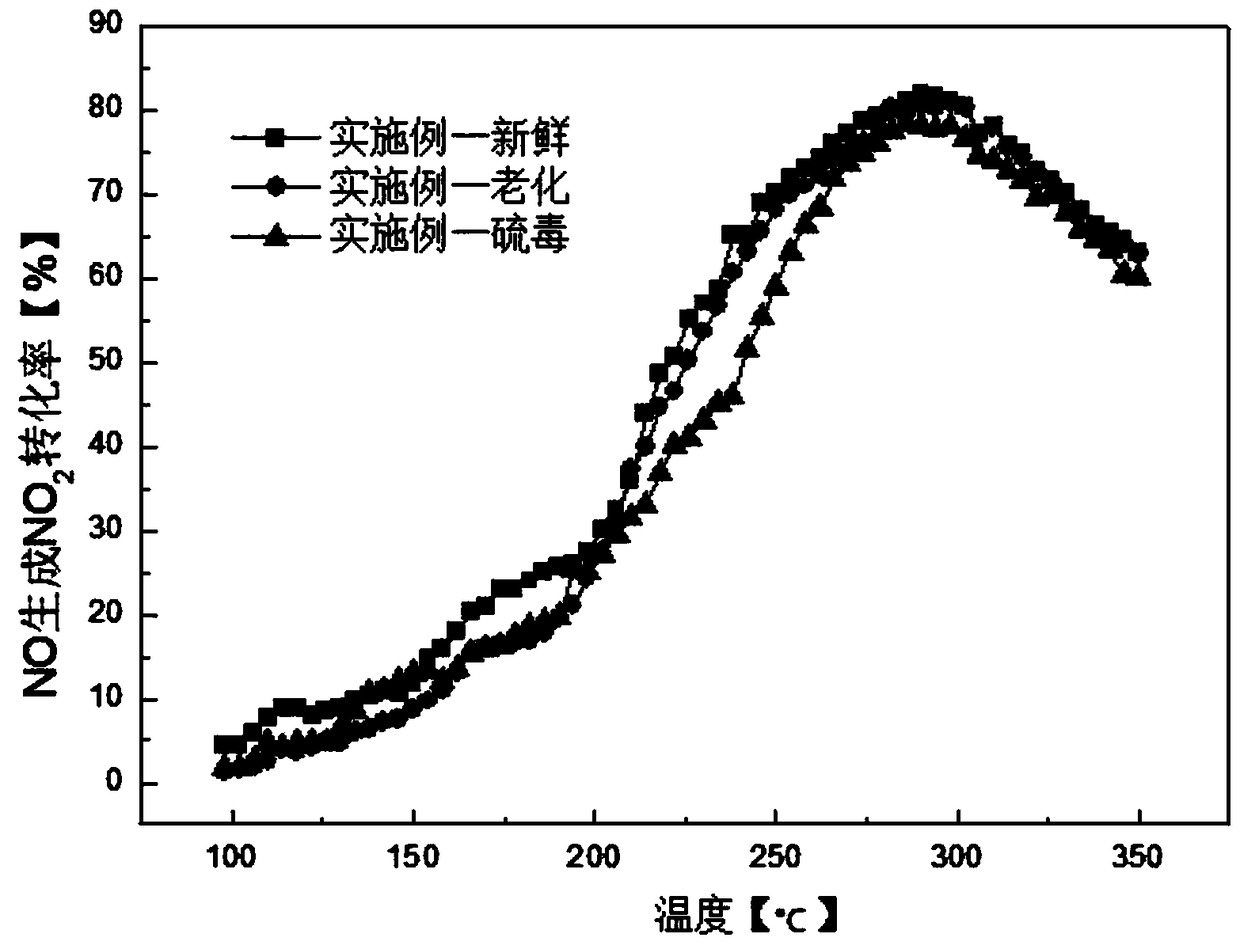

Embodiment 1

[0037] The present embodiment provides a kind of preparation method for the oxidation catalyst of diesel vehicle, comprises the following steps:

[0038] 1) Dissolve cerium nitrate, manganese nitrate, and samarium nitrate in a solution containing surfactant according to a certain molar mass ratio, then add precipitant tetramethylammonium hydroxide to adjust the pH to 9-12, the reaction is complete, and place for aging for 5 hours , After centrifugation and washing to obtain a precipitate, the obtained precipitate was baked at 120°C for 12h, then calcined in a muffle furnace at 500°C for 10h, ground and crushed, and then calcined at 800°C for 10h to obtain CeO containing a fluorite phase. 2 , mullite phase SmMn2 o 5 , spinel phase Mn 3 o 4 Mixed-phase catalyst; then add the mixed-phase catalyst and aluminum sol to deionized water and 50% absolute ethanol, stir for 1-3h until the slurry is uniform, and then grind the slurry with a sand mill until the particle size d50 of the s...

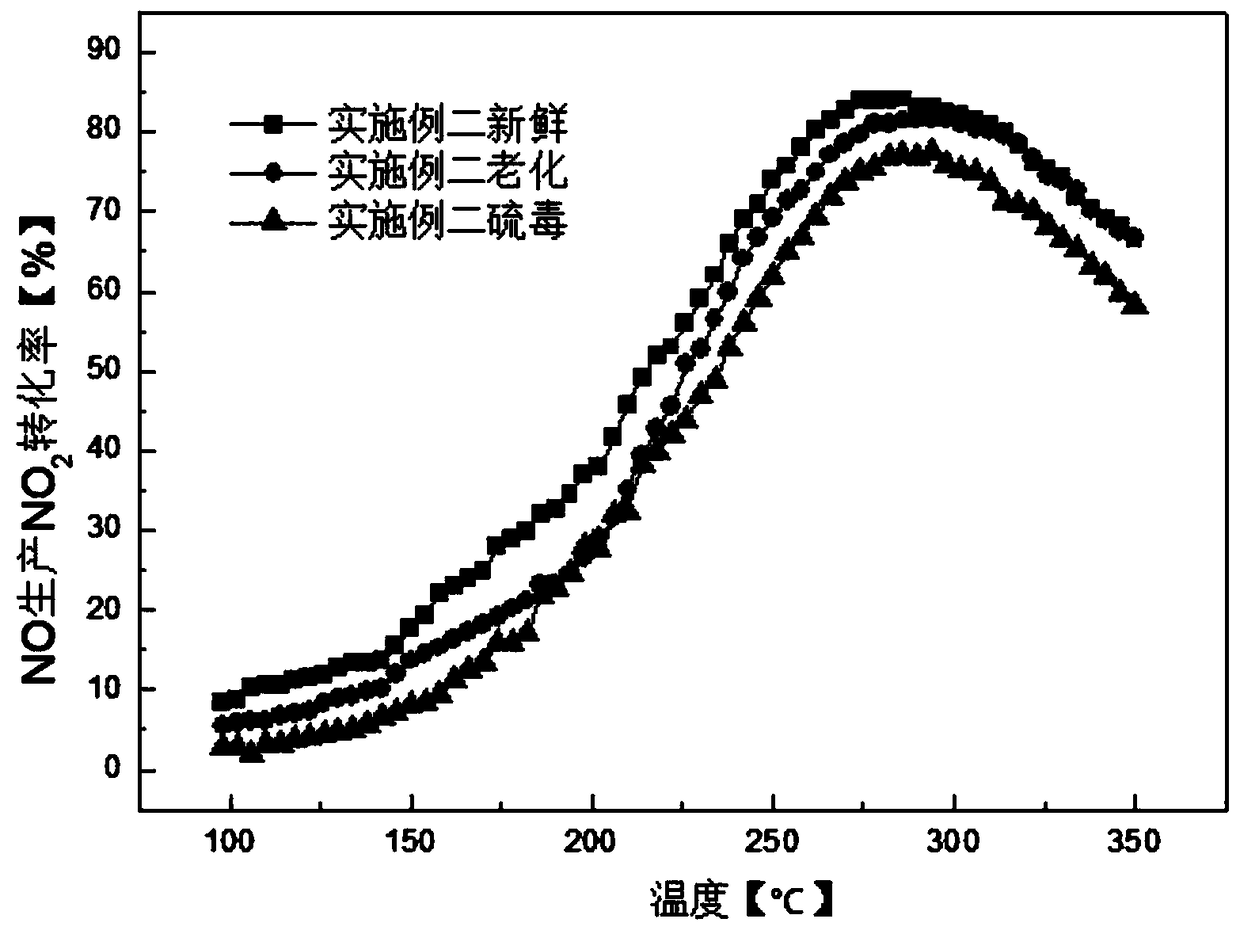

Embodiment 2

[0045] This embodiment has the following differences from Embodiment 1:

[0046] ①What prepared in step 2) is the Al loaded with 1.2%Pt and 0.8%Pd 2 o 3 , Al loaded with 1.2% Pt and 0.8% Pd 2 o 3 and Al without precious metals 2 o 3 The mass ratio is 1:1;

[0047] ② What is prepared in step 3) is Al loaded with 1% Pd 2 o 3 , Al loaded with 1% Pd 2 o 3 and Al without precious metals 2 o 3 The mass ratio is 2:3;

[0048] ③The weight gain of the bottom layer of the coated carrier is 105g / L, and the mixed-phase catalyst is 1.2g / in 3 , alumina 0.5g / in 3 , precious metal 8.25g / ft 3 ;Surface weight gain 40g / L, molecular sieve 0.35g / in 3 , precious metal 2.75g / ft 3 , alumina 0.25g / in 3 .

[0049] The rest are the same as in Embodiment 1, and will not be repeated here.

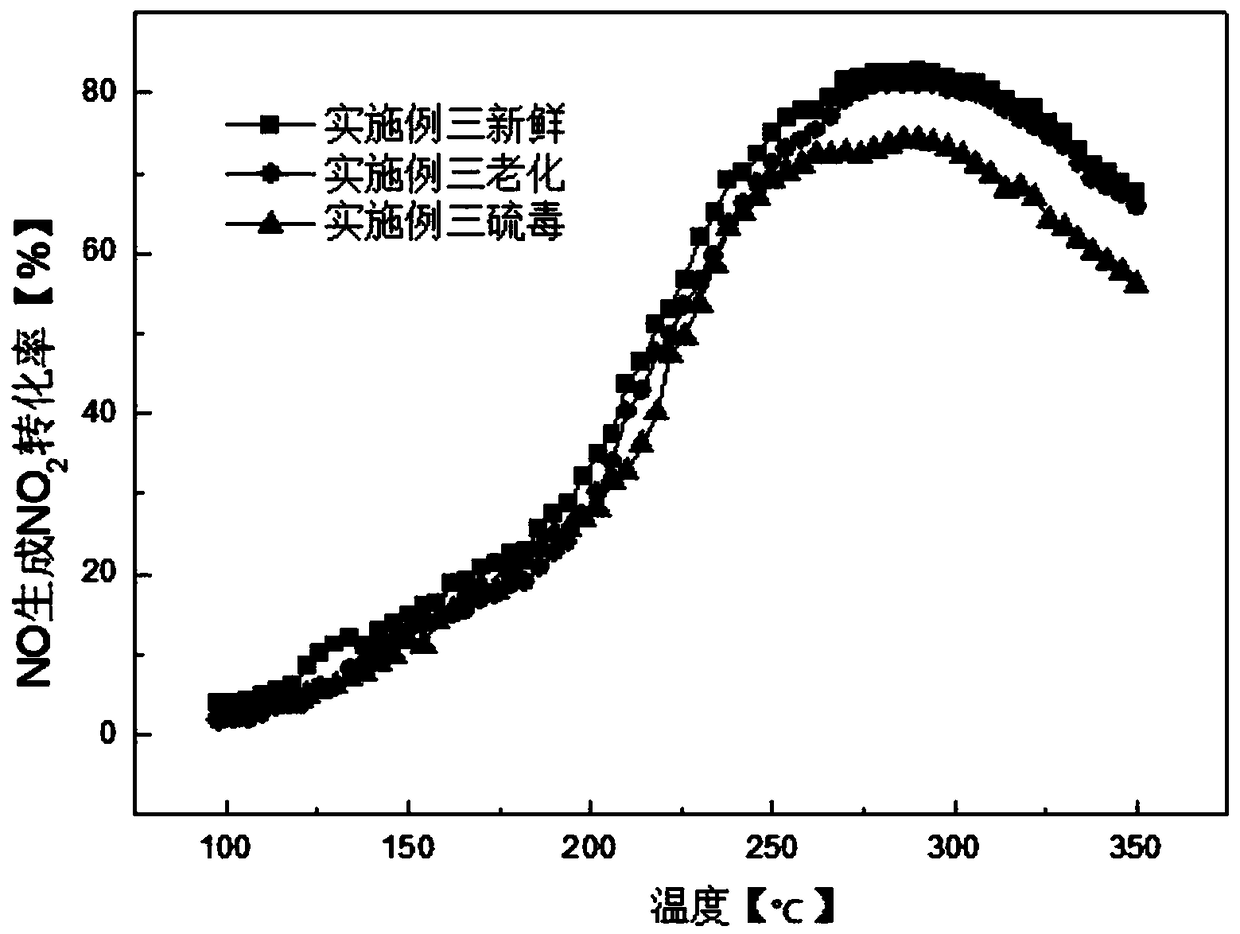

Embodiment 3

[0051] This embodiment has the following differences from Embodiment 1:

[0052] 1. What is prepared in step 2) is the Al loaded with 0.6% Pt and 0.4% Pd 2 o 3 , Al loaded with 0.6% Pt and 0.4% Pd 2 o 3 and Al without precious metals 2 o 3 The mass ratio is 1:1;

[0053] ② What is prepared in step 3) is Al loaded with 1% Pd 2 o 3 , Al loaded with 1% Pd 2 o 3 and Al without precious metals 2 o 3 The mass ratio is 1:4;

[0054] ③The weight gain of the bottom layer of the coated carrier is 105g / L, and the mixed-phase catalyst is 1.2g / in 3 , alumina 0.5g / in 3 , precious metal 4.125g / ft 3 ;Surface weight gain 40g / L, molecular sieve 0.35g / in 3 , precious metal 1.375g / ft 3 , alumina 0.25g / in 3 .

[0055] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com