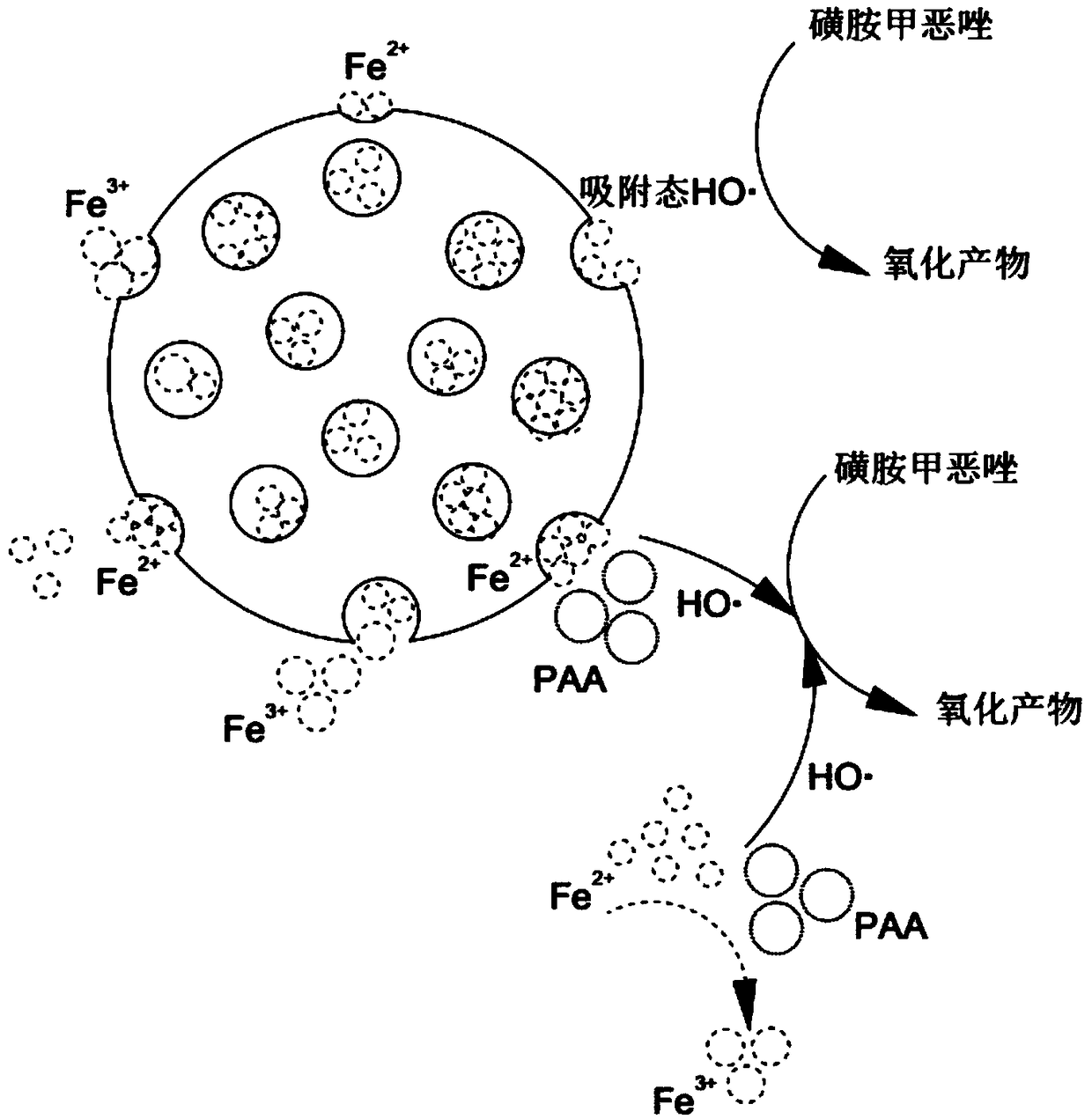

Method for removing sulfonamides in water by using modified zeolite to activate peracetic acid

A technology of sulfonamide drugs and peracetic acid, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, water pollutants, etc., can solve the problems of failure, difficulty in storage, and low utilization efficiency. , to achieve the effect of low application cost, avoid secondary pollution, and increase contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: a kind of utilization Fe 2+ / artificial zeolite activated peracetic acid removes the method for sulfa antibiotics in water, it comprises the following steps:

[0031] S1. Catalyst preparation: Grind artificial zeolite into 200-mesh uniform fine powder, weigh a certain mass and add it to dilute sulfuric acid with a concentration of 0.05mol / L, so that the acid solution just submerges the powder, stir evenly and let it stand for 24 hours. Wash with deionized water until the pH is 6.8, and dry in a muffle furnace at 100°C. According to zeolite, Fe 2+ Add a certain amount of dried fine powder into the ferrous sulfate solution with a concentration of 0.2mol / L at a mass ratio of 60:1, soak for 20 hours, wash with deionized water for 3 to 4 times, and centrifuge to separate the solid Dry it in an oven at 100°C to make a catalyst.

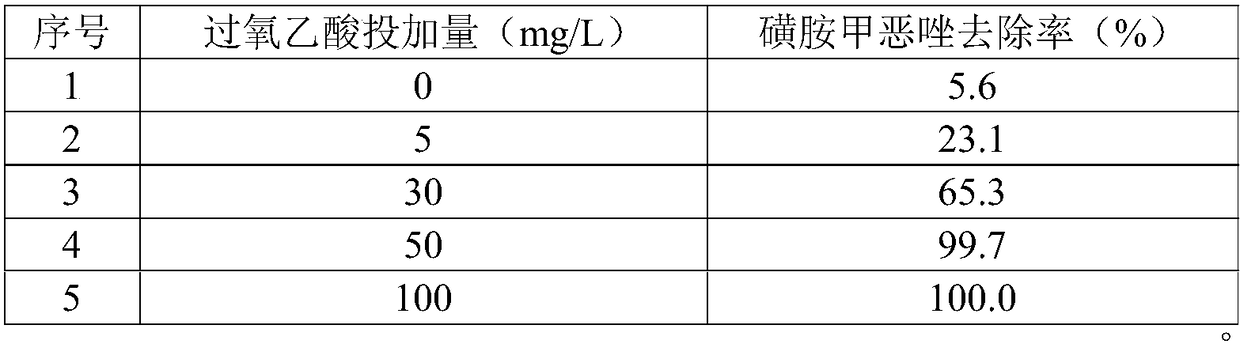

[0032] S2. Oxidation reaction: Add 0.4mL to 50mL of peracetic acid solution with a concentration of 10g / L to 50mL 0.1mg / L sulfameth...

Embodiment 2

[0035] Embodiment 2: a kind of utilization Fe 2+ / artificial zeolite activated peracetic acid removes the method for sulfa antibiotics in water, it comprises the following steps:

[0036] S1. Catalyst preparation: Grind artificial zeolite into 200-mesh uniform fine powder, weigh a certain mass and add it to dilute sulfuric acid with a concentration of 0.1mol / L, so that the acid solution just submerges the powder, stir evenly and let it stand for 19 hours. Wash with deionized water until the pH is 7.0, and dry in a muffle furnace at 100°C. According to zeolite, Fe 2+ Add a certain amount of dried fine powder into the ferrous sulfate solution with a concentration of 0.2mol / L at a mass ratio of 55:1, soak for 24 hours, wash with deionized water for 3 to 4 times, and centrifuge to separate the solid Place it in an oven at 70°C and dry it to make a catalyst.

[0037] S2. Oxidation reaction: Add 0.5mL to 100mL of peracetic acid solution with a concentration of 10g / L to 100mL 0.5m...

Embodiment 3

[0040] Embodiment 3: a kind of utilization Fe 2+ / artificial zeolite activated peracetic acid removes the method for sulfa antibiotics in water, it comprises the following steps:

[0041] S1. Catalyst preparation: Grind the artificial zeolite into 300-mesh uniform fine powder, weigh a certain mass and add it to dilute sulfuric acid with a concentration of 0.1mol / L, so that the acid solution just immerses the powder, stir evenly and let it stand for 24 hours. Wash with deionized water until the pH is 6.8, and dry in a muffle furnace at 100°C. According to zeolite, Fe 2+ Add a certain amount of dried fine powder into the ferrous sulfate solution with a concentration of 0.4mol / L at a mass ratio of 65:1, soak for 24 hours, wash with deionized water for 3 to 4 times, and centrifuge to separate the solid Place it in an oven at 90°C and dry it to make a catalyst.

[0042] S2. Oxidation reaction: Add 10g / L peracetic acid solution 2.0mL to 200mL 1.5mg / L sulfamethoxazole wastewater, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com