Combined restoration method for heavy metal polluted farmland soil

A composite repair and heavy metal technology, applied in the restoration of polluted soil, etc., can solve the problems of high manpower and financial resources, unfavorable popularization and application, and reduced soil fertility, etc., to achieve reduced repair costs, strong ion exchange capacity, and good results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] (1) For farmland soil polluted by heavy metals, 10 days before plowing, apply 50-200kg of heavy metal passivation agent per mu, plow and mix well, and plow the soil to a depth of about 10-30cm;

[0060] (2) Select high-quality soybean Zhongdou 41 seeds, and plant soybeans in spring, with a seeding rate 3 ; Normal management of soybean growth process; soybean straw recycling after harvesting soybeans in summer;

[0061] (3) Before the farmland soil after the soybean harvest is cultivated, apply 50-200kg of heavy metal passivation agent per mu, plow and mix well, and the plow depth is about 10-30cm;

[0062] (4) Select No. 9 seeds of rape heza which are resistant to bolting, full of grains, and free of diseases and insect pests, and sow in autumn with a seeding rate 3 ; Rapeseed growth process is normally managed; after the rapeseed is harvested, the rapeseed straw is recycled.

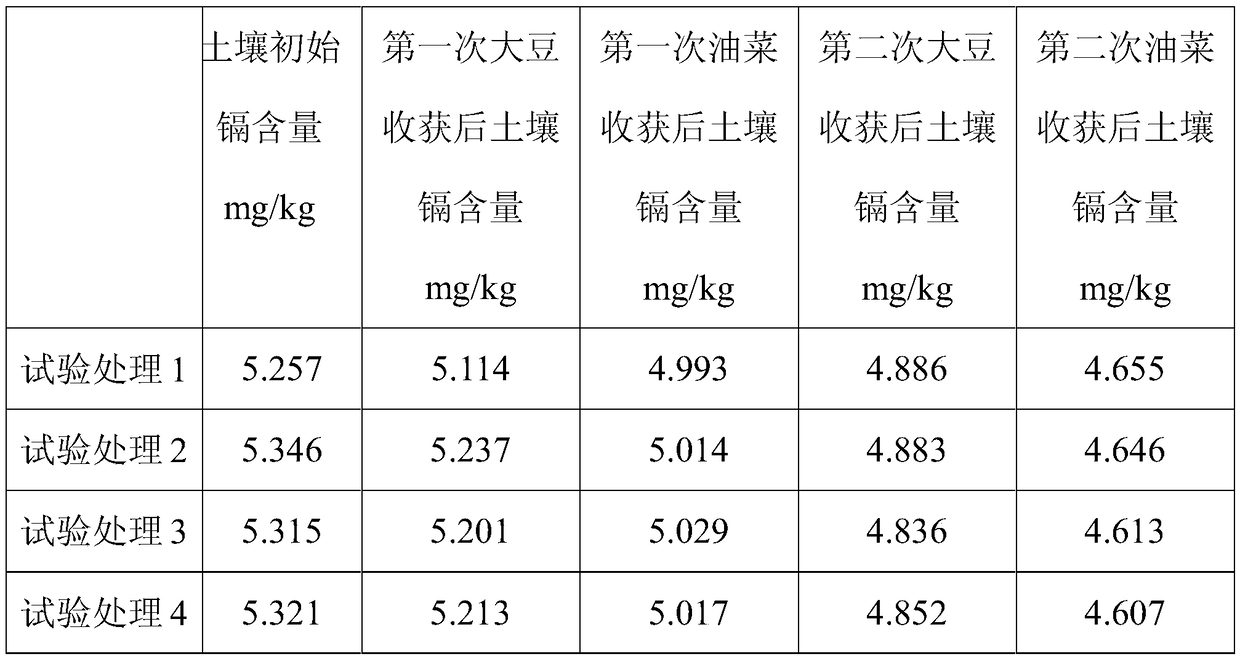

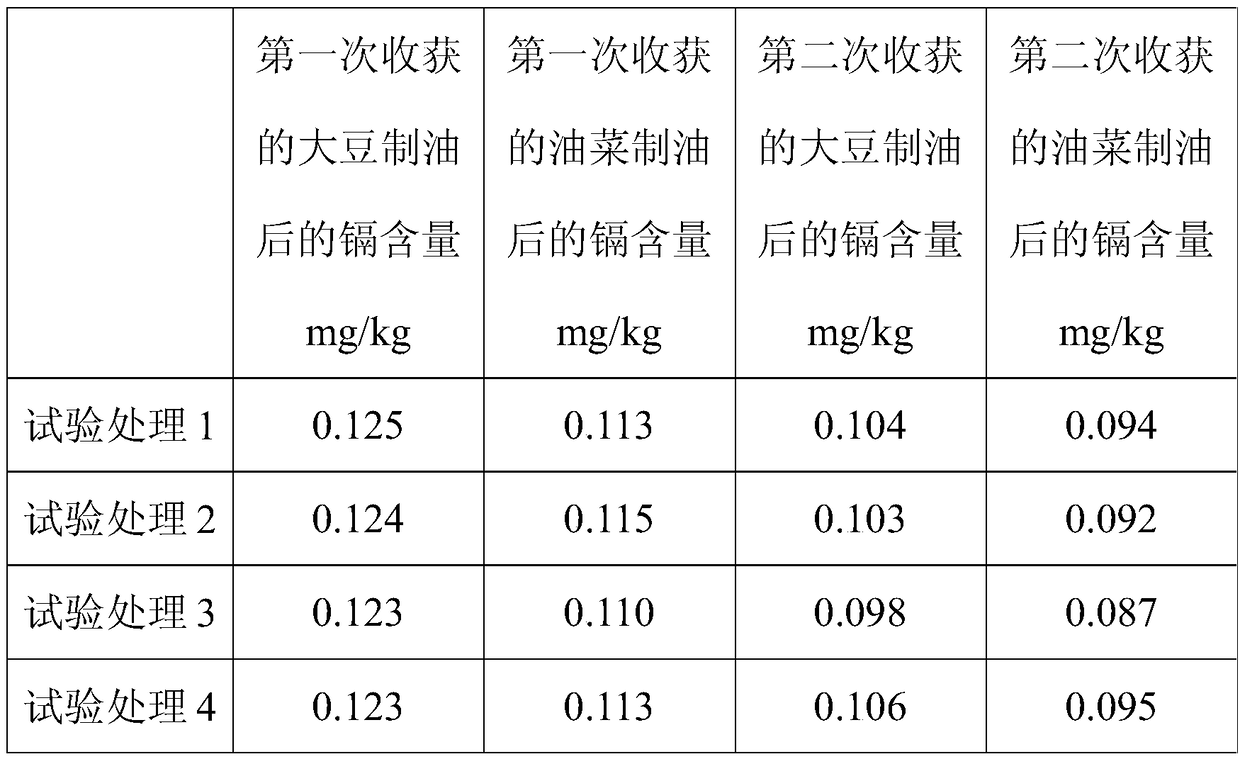

[0063] (5) According to the planting method (1)-(4), the test will be carried out after two y...

Embodiment 2

[0077] Heavy metal activator production method:

[0078] (1) Rice straw is crushed through a 20-mesh sieve, added to 4% NaOH solution at a weight ratio of 1:10, heated at 100°C for 30 minutes, filtered, the filter residue is taken, washed with water until neutral, and dried at 105°C to obtain delignification straw.

[0079] (2) Add 5% urea of the weight of the delignified straw to the delignified straw, carry out composting and fermentation to maturity, add 2% rapeseed meal of the weight of the delignified straw after fermentation, and add Bacillus with phosphorus-solubilizing function, The Rhizopus and Aspergillus make the concentration of the heap to reach 0.1 billion cfu / g, carry out the secondary fermentation for 10 days, and obtain straw bio-organic fertilizer after the end.

[0080] (3) Add 5% oxalic acid by organic fertilizer weight to straw bio-organic fertilizer and mix to prepare heavy metal activator.

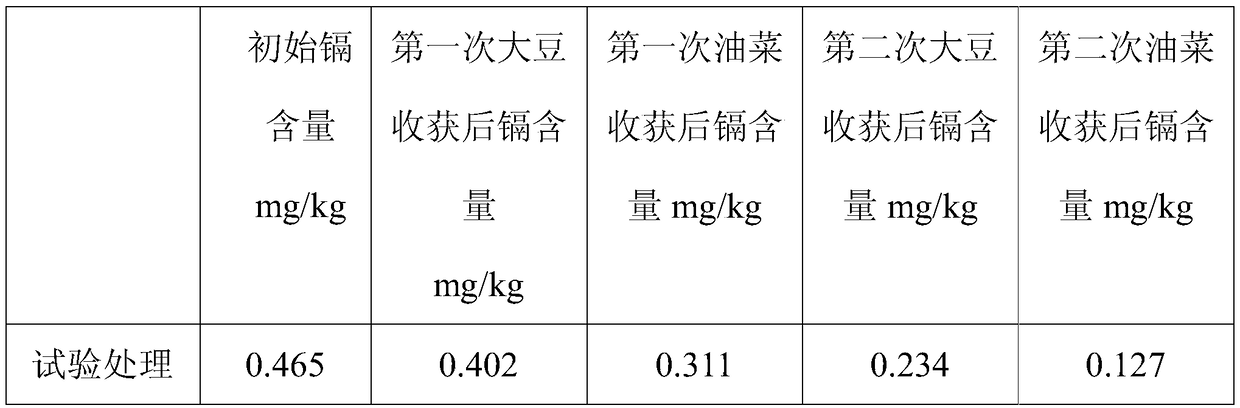

[0081] After the composite restoration of Example 1, when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com