Oil-based mud and oil-bearing cuttings recycling system and method

An oil-based mud and recycling technology, applied in the field of resources and environment, can solve the problems of secondary pollution, tail gas not easy to meet the standard, and skin accumulation in the kiln, so as to improve the disposal efficiency and effect, easily meet the standard of tail gas treatment, and reduce the environmental pollution. pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

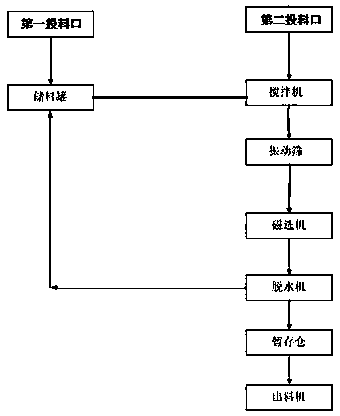

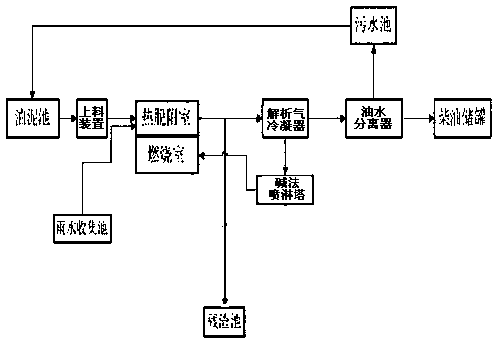

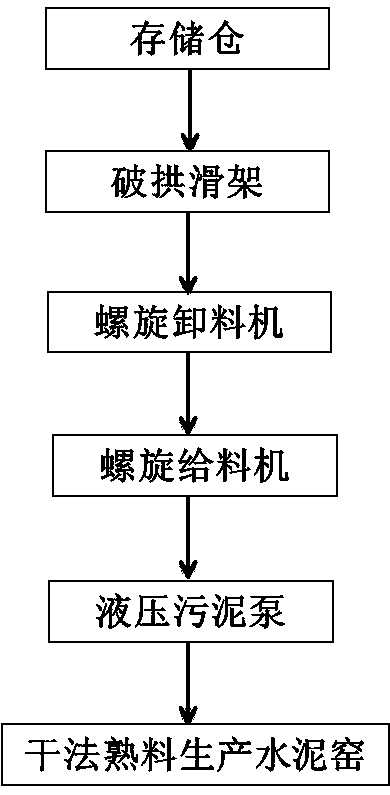

[0033] Such as figure 1 , figure 2 with image 3 As shown, the oil-based mud and oily cuttings resource utilization system includes a mixed conditioning system, a thermal desorption system and a cement kiln co-processing system;

[0034] The mixing and tempering system includes a storage tank, a mixer, a vibrating screen, a magnetic separator, a dehydrator, a temporary storage bin and a discharge machine, the storage tank, a mixer, a vibrating screen, a magnetic separator, a dehydrator, a temporary The warehouse and the discharge machine are connected in sequence;

[0035] The thermal desorption system includes an oil sludge tank, a thermal desorption furnace, an analytical gas condenser, an oil-water separator, a diesel oil storage tank, a sewage tank and a residue tank,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com