High-molecular coagulation cohesive dust suppression agent and preparation method thereof

A technology of dust suppressant and polymer, which is applied in the field of polymer coagulation-bonded dust suppressant and its preparation, can solve the problems of poor suppression effect of fine dust covered with dust-proof net, secondary pollution of the environment, waste of water resources, etc. Achieve the effects of facilitating the implementation of dust suppression operations, improving coverage efficiency, and reducing internal friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

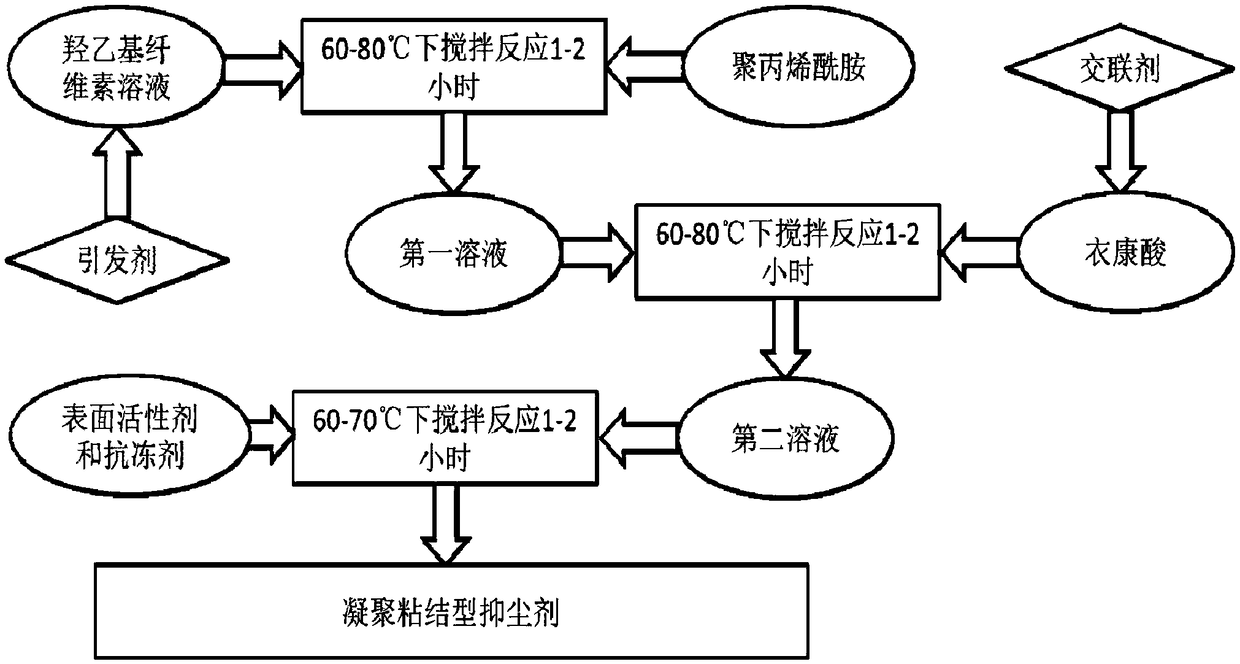

[0028] The present invention also provides a kind of preparation method of above-mentioned macromolecule cohesive bonding type dust suppression agent, such as figure 1 As shown, it includes the following steps:

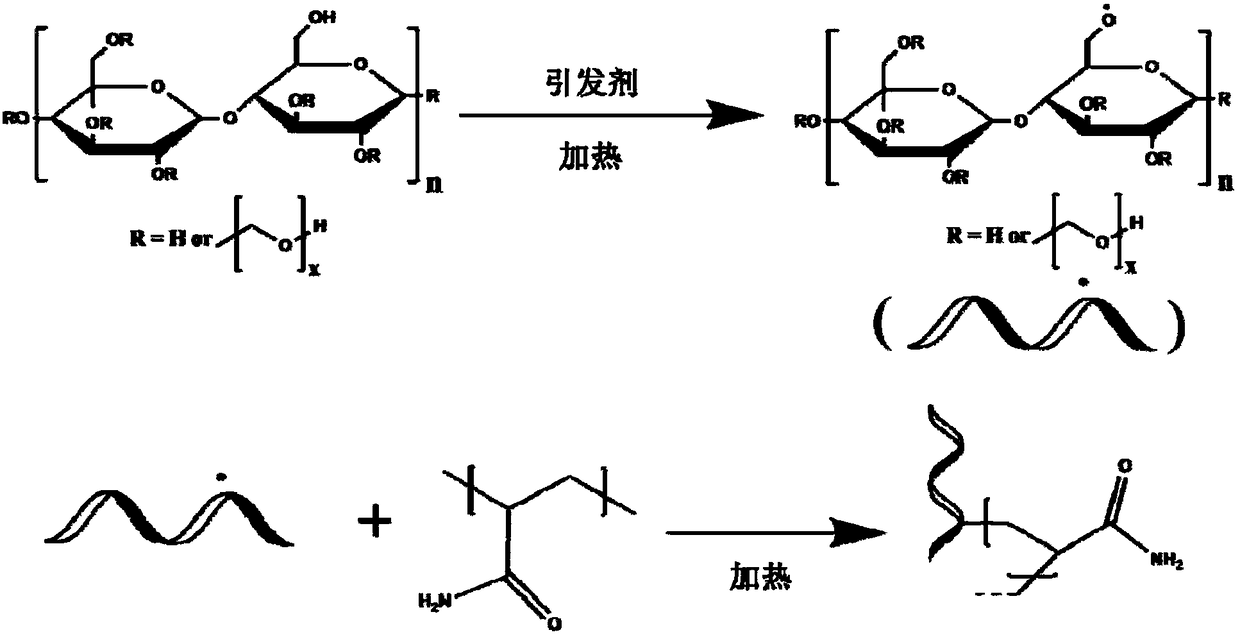

[0029] Step 1: Dissolve hydroxyethyl cellulose and polyacrylamide respectively in water according to the proportion, mix them together after dissolving evenly, add the initiator in proportion, and stir and react at 60°C-80°C for 1 hour-2 hours to obtain first solution;

[0030]

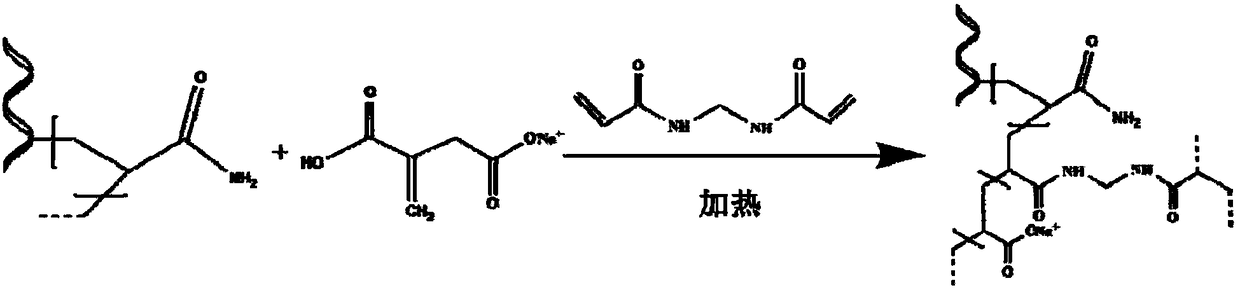

[0031] Step 2, adding neutralized itaconic acid and a cross-linking agent to the first solution in proportion, stirring and reacting at 60°C-80°C for 1 hour-2 hours to obtain a second solution;

[0032]

[0033] Step 3: Add antifreeze and surfactant to the above second solution according to the proportion, and stir and react at 60°C-70°C for 1-2 hours to obtain the above-mentioned polymer coagulation-bonding dust suppressant.

Embodiment 1

[0036] Weigh 1.5g of hydroxyethyl cellulose and dissolve it in 200ml of water, and another 3g of polyacrylamide is dissolved in 50ml of water and add 0.1g of ammonium cerium nitrate, mix with hydroxyethyl cellulose, and stir at 65°C for 1 hour. . 7ml of itaconic acid with a neutralization degree of 80% and 0.08g of N,N-methylenebispolyacrylamide were added thereto, and the mixture was kept at a constant temperature of 65°C for 1 hour with stirring. Add 0.03 g of potassium monododecyl phosphate and 0.05 g of sodium dodecyl sulfonate therein, add water to 300 ml, and stir at 60° C. for 1 hour to react. Final test related performance.

Embodiment 2

[0038] Weigh 1.5g of hydroxyethyl cellulose and dissolve it in 200ml of water, and another 3g of polyacrylamide is dissolved in 50ml of water and add 0.1g of ammonium cerium nitrate, mix with hydroxyethyl cellulose, and stir at 65°C for 1 hour. . 8 ml of itaconic acid with a neutralization degree of 80% and 0.08 g of N,N-methylenebispolyacrylamide were added thereto, and the mixture was kept at a constant temperature of 65° C. for 1 hour with stirring. Add 0.03 g of potassium monododecyl phosphate and 0.05 g of sodium dodecyl sulfonate therein, add water to 300 ml, and stir at 60° C. for 1 hour to react. Final test related performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com