High-strength flame-retardant leather sewing thread

A sewing thread, high-strength technology, applied in yarn, textile and papermaking, fiber processing and other directions, can solve the problems of reducing the production efficiency of leather products, lowering the grade of leather products, and blocking needle holes, improving health care and bacteriostatic functions, inhibiting The production of mold, the effect of improving the grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

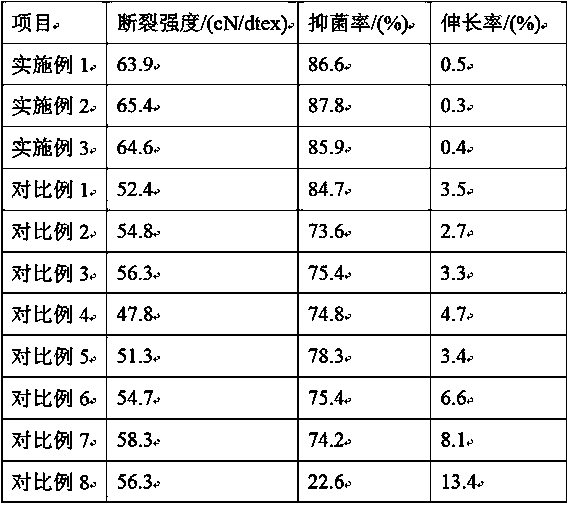

Examples

Embodiment 1

[0018] A high-strength flame-retardant leather sewing thread is made of the following raw materials in parts by weight: 33 aramid fibers, 21 bamboo fibers, 21 cotton fibers, 16 ceramic fibers, and 12 polyacrylonitrile-based carbon fibers.

[0019] Described cotton fiber, length is 50~55mm.

[0020] The ceramic fiber, which contains 0.2% nano-titanium oxide by weight of the ceramic fiber.

[0021] A preparation method of high-strength flame-retardant leather sewing thread, comprising the following steps:

[0022] (1) Bamboo fiber and cotton fiber are mixed and woven with a linear density of 1.2dtex, which can improve the strength and antibacterial properties of sewing threads, inhibit the generation of mold, avoid the phenomenon of sewing thread moldy after long-term use of leather products, and prolong the use of leather products life, core yarn;

[0023] (2) Soak the core yarn in a sodium selenite solution with a concentration of 140mg / L for 7 hours at a temperature of 13°C...

Embodiment 2

[0028] A high-strength flame-retardant leather sewing thread is made of the following raw materials in parts by weight: 34 aramid fibers, 22 bamboo fibers, 22 cotton fibers, 17 ceramic fibers, and 13 polyacrylonitrile-based carbon fibers.

[0029] Described cotton fiber, length is 50~55mm.

[0030] The ceramic fiber contains 0.3% nano titanium oxide by weight of the ceramic fiber.

[0031] The method of preparation and use is the same as in Example 1.

Embodiment 3

[0033] A high-strength flame-retardant leather sewing thread is made of the following raw materials in parts by weight: 35 parts by weight of aramid fiber, 23 parts by weight of bamboo fiber, 23 parts by weight of cotton fiber, 18 parts by weight of ceramic fiber, and 14 parts by weight of polyacrylonitrile-based carbon fiber.

[0034] Described cotton fiber, length is 50~55mm.

[0035] The ceramic fiber, which contains 0.4% nano-titanium oxide by weight of the ceramic fiber.

[0036] The method of preparation and use is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com