An electrochromic film, its preparation method and application, and an electrochromic device

An electrochromic device and electrochromic technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of high production cost, complicated preparation method, high energy consumption, etc., and achieve short electrochromic response time, easy preparation The method is simple and easy, and the effect of saving power resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

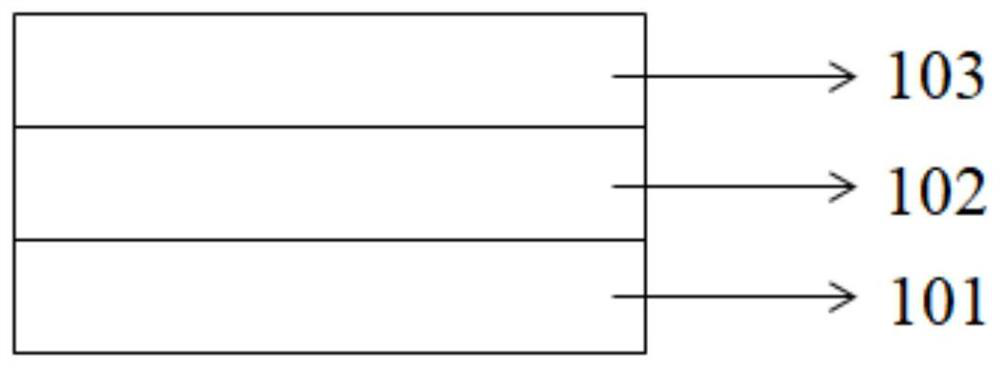

[0066] figure 1 The structure diagram of the electrochromic thin film provided in this embodiment includes an ion storage layer 101 , a conductive layer 102 and an electrochromic layer 103 from bottom to top.

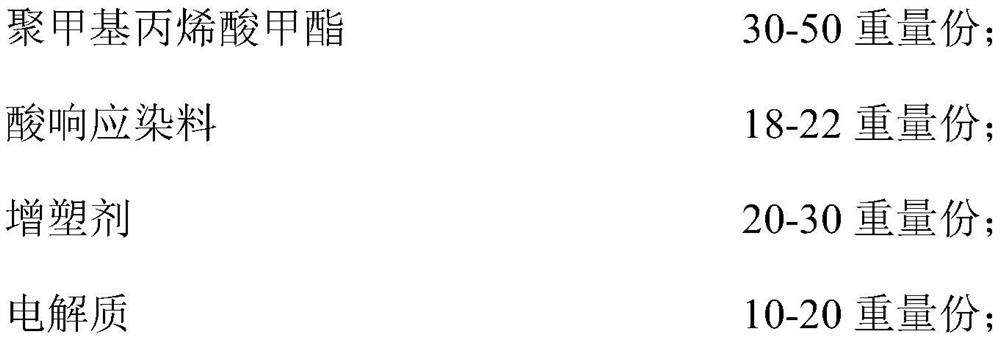

[0067] Wherein, the electrochromic layer includes the following components in parts by weight:

[0068]

[0069] The conductive layer comprises the following components in parts by weight:

[0070] 50 parts by weight of polymethyl methacrylate;

[0071] 30 parts by weight of plasticizer;

[0072] Electrolyte 20 parts by weight.

[0073] The ion storage layer comprises the following components in parts by weight:

[0074]

[0075] The acid-responsive dye is a mixture of N-substituted p-phenylenediamine derivatives and thermosensitive black derivatives at a mass ratio of 1:3; the plasticizer is ethylene carbonate; and the electrolyte is lithium perchlorate.

[0076] In the ion storage layer, the electrogenic acid is N-substituted p-phenylenediamine derivative, ...

preparation example 2

[0082] The only difference with Preparation Example 1 is that in the acid response dye, the mass ratio of N-substituted p-phenylenediamine derivatives and thermosensitive black derivatives is 1:2.5 (Preparation Example 2), 1:1 (Preparation Example 3), 1:5 (Preparation Example 4).

preparation example 5

[0084] An electrochromic film comprises an ion storage layer, a conductive layer and an electrochromic layer from bottom to top.

[0085] Wherein, the electrochromic layer includes the following components in parts by weight:

[0086]

[0087] The conductive layer comprises the following components in parts by weight:

[0088] 40 parts by weight of polymethyl methacrylate;

[0089] 40 parts by weight of plasticizer;

[0090] Electrolyte 15 parts by weight.

[0091] The ion storage layer comprises the following components in parts by weight:

[0092]

[0093] The acid-responsive dye is a mixture of urea derivatives substituted by aromatic amines and rhodamine derivatives in the form of spironolactam at a mass ratio of 1:2; the plasticizer is propylene carbonate; the electrolyte is bistrifluoromethanesulfonyl lithium amide.

[0094] In the ion storage layer, the electrogenic acid is a urea derivative substituted by aromatic amine, and the electrogenic base is imidazol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com