TFT substrate and manufacturing method thereof

A manufacturing method and substrate technology, which can be applied to electrical components, electrical solid devices, circuits, etc., can solve the problems of metal electrode line leftover, film breakage of passivation layer structure, short circuit, etc., and achieve excellent blocking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

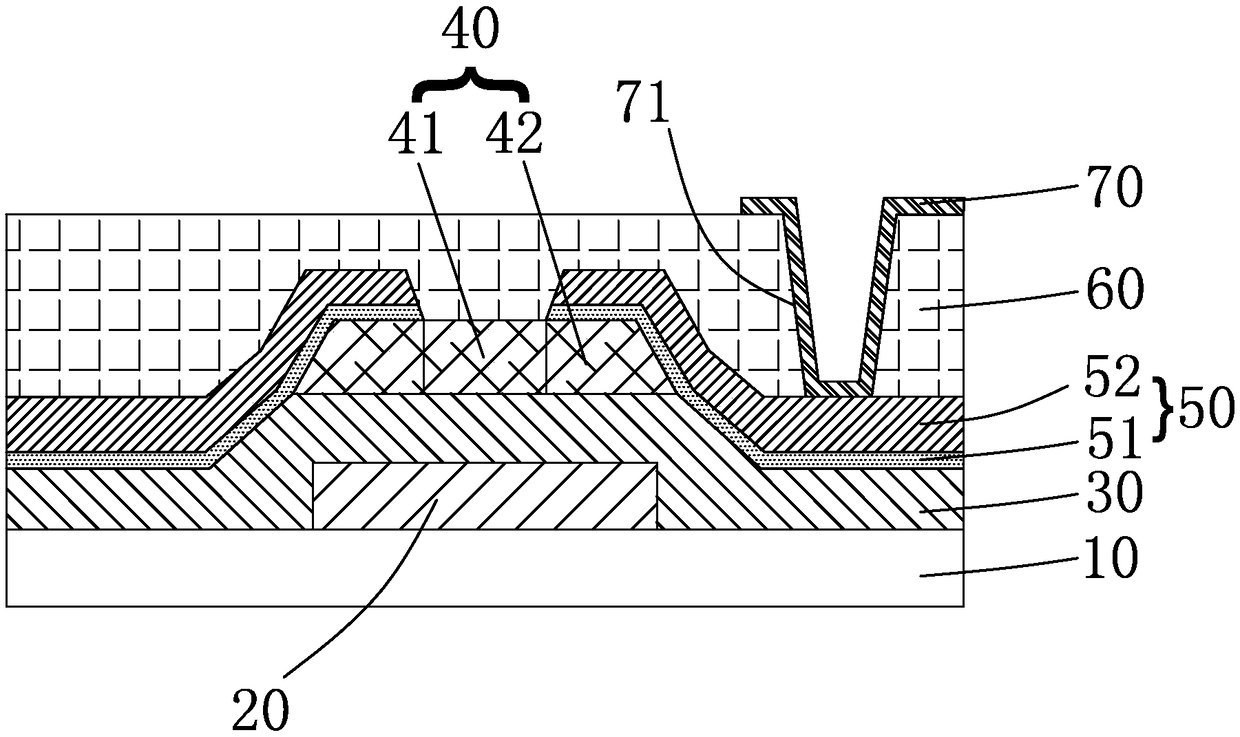

[0036] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

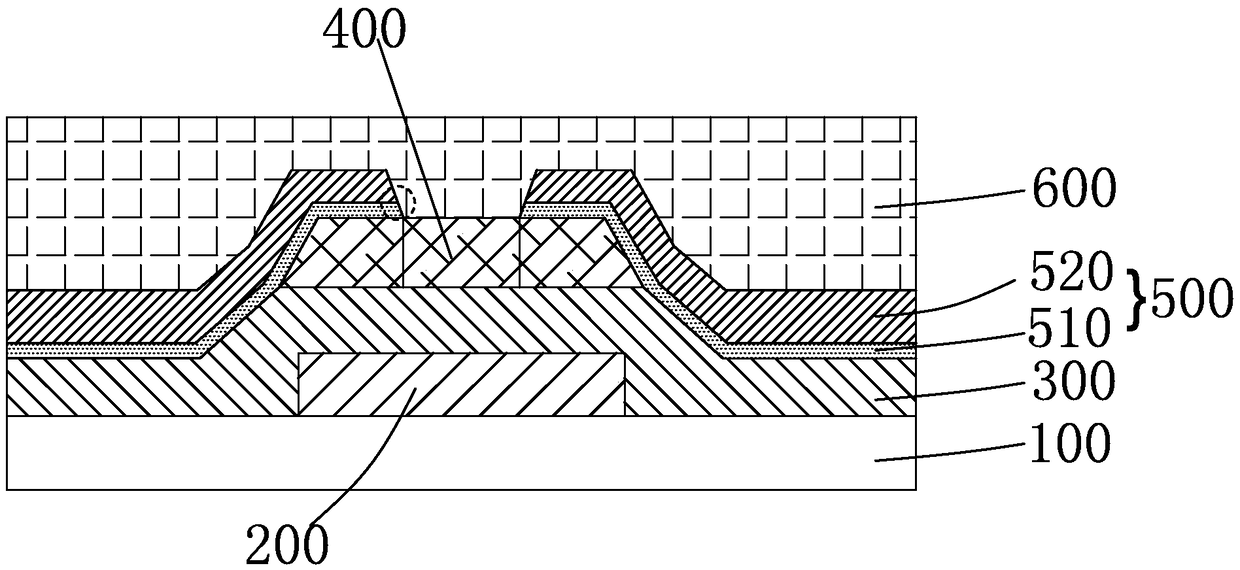

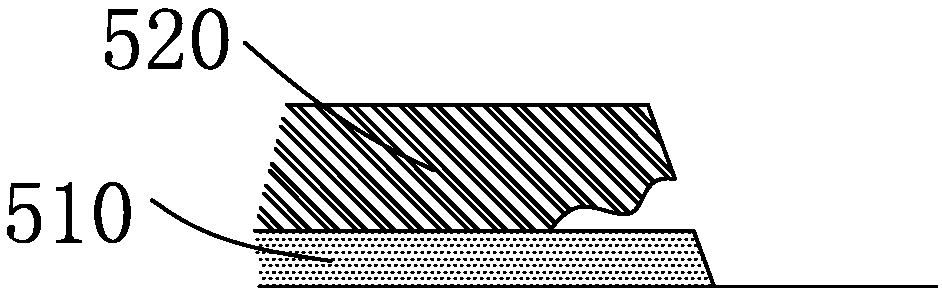

[0037] see image 3 , the present invention provides a TFT substrate, comprising a base substrate 10, a gate 20 disposed on the base substrate 10, a gate insulating layer 30 disposed on the base substrate 10 and the gate 20, a gate insulating layer 30 disposed on the gate insulating The layer 30 corresponds to the active layer 40 above the gate 20 , the source / drain 50 disposed on both sides of the active layer 40 , and the passivation layer 60 covering the source / drain 50 .

[0038] Wherein, the base substrate 10 is a transparent substrate, such as glass or quartz.

[0039] The gate 20 is a single-layer metal film or a multi-layer metal film, and its material is copper (Cu), aluminum (A1), molybdenum (Mo), titanium (Ti), silver (Ag), gold (A...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap