Hybrid excitation wind driven generator based on split magnetic steels

A technology of wind power generator and hybrid excitation, which is applied in synchronous machines, electrical components, electromechanical devices, etc., can solve the problems of large loss of excitation windings, achieve the effects of reducing magnetic flux leakage, reducing end effects, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

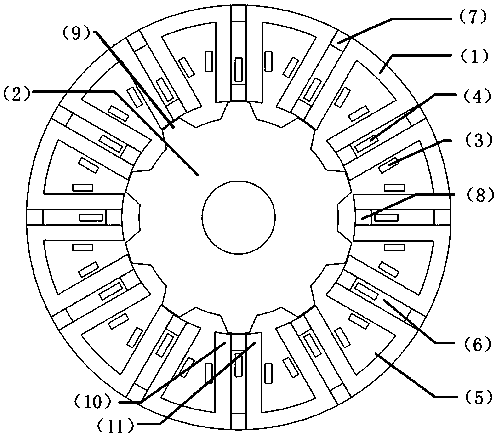

[0029] A hybrid excitation wind generator based on split magnets, including a stator (1), a rotor (2), an armature winding (3), a DC field winding (4), a stator slot (5), and a magnet slot (6) , upper magnetic steel (7), lower magnetic steel (8), and rotor helical teeth (9), magnetic steel left stator (10) and magnetic steel right stator (11).

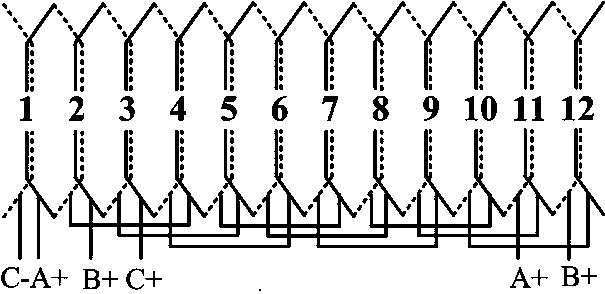

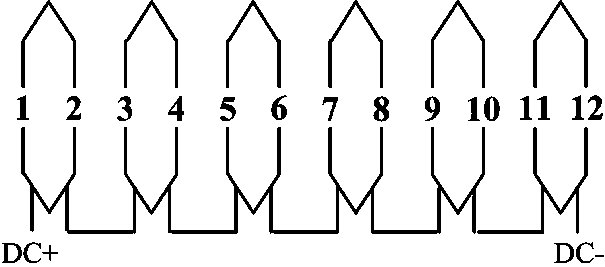

[0030] as attached figure 1 As shown, taking a 12-slot and 10-tooth split-magnet hybrid excitation wind turbine structure as an example, the stator (1) is designed as a modular structure, and 12 stators are arranged concentrically and equidistantly around the rotor. There are magnetic steel slots between the stators. In order to reduce the loss of the magnetic steel under the same amount of permanent magnets, the permanent magnets in each magnetic steel slot are divided into two sections, which a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com