Fruit and vegetable waste and kitchen waste cooperative treatment process

A technology for fruit and vegetable waste and kitchen waste, which is applied in the direction of combined biological treatment, biological organic part treatment, fertilizer made of biological waste, etc. To achieve the effect of shortening the fermentation period and increasing the fermentation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

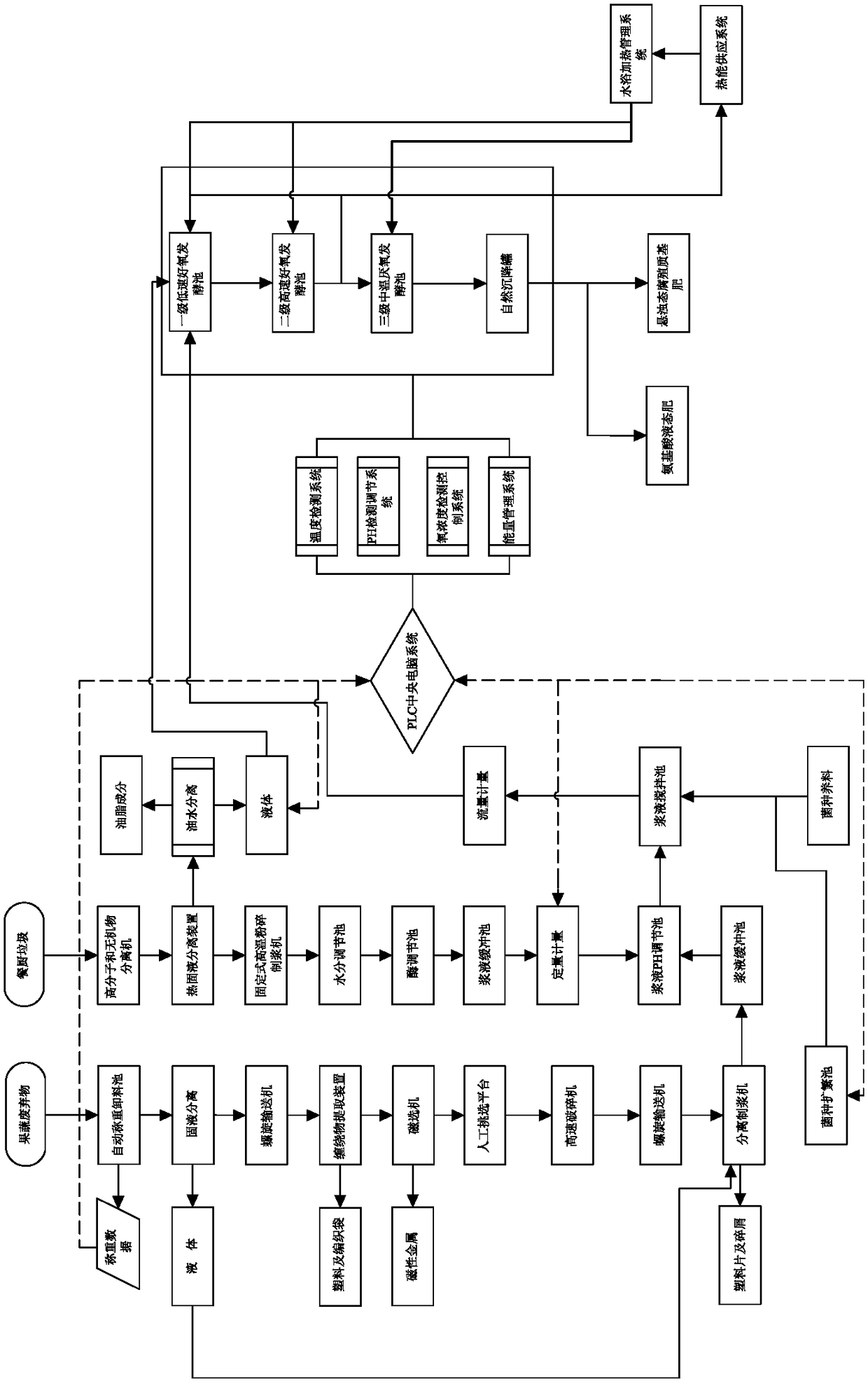

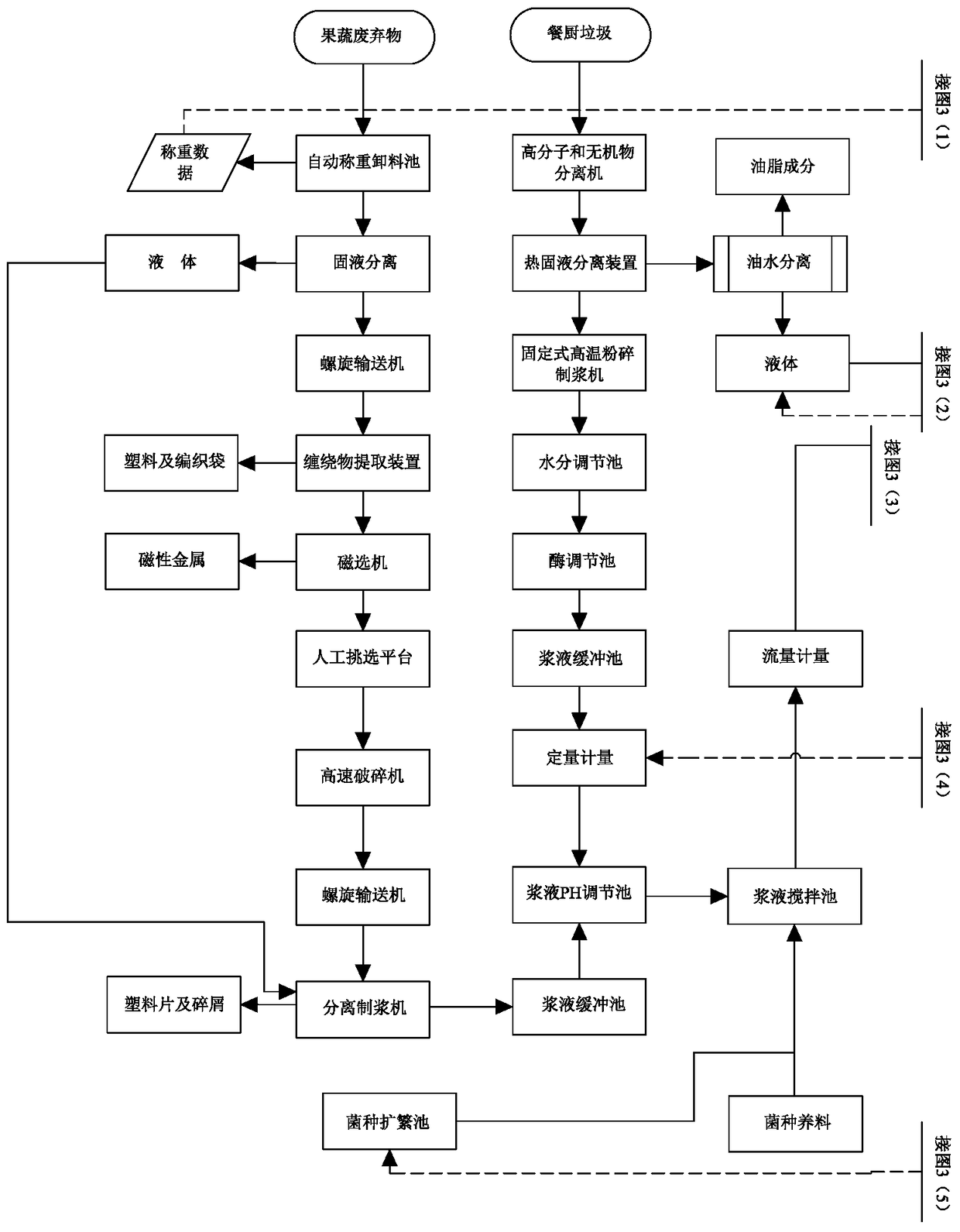

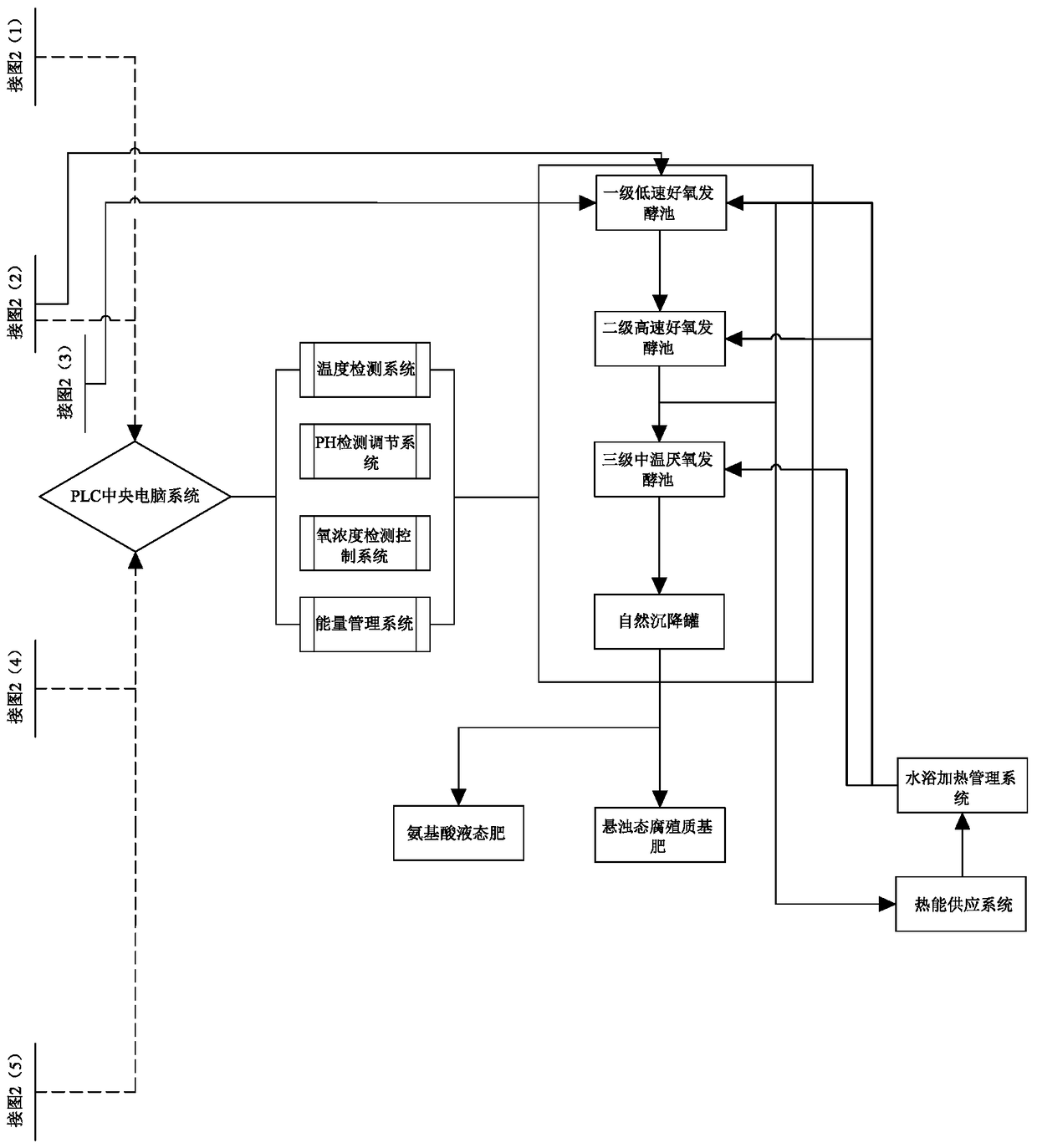

[0023] Such as Figure 1 to Figure 3 As shown, the present invention discloses a co-processing process of fruit and vegetable waste and food waste, which includes three parts: fruit and vegetable waste pretreatment, food waste pretreatment and co-processing.

[0024] First, carry out pretreatment of fruit and vegetable waste and food waste.

[0025] The details of fruit and vegetable waste pretreatment are as follows:

[0026] Fruits and vegetables are sent to the automatic weighing discharge pool, in which the weighing sensor is integrated in the discharge pool, which can automatically upload the weighing data to the PLC central computer system. Another function of the unloading tank is to separate the solid and liquid at the bottom, and separate the liquid and solid materials. The separated solid material is conveyed by a screw conveyor, which can ensure the uniform feeding and transportation of the fruit and vegetable waste, and further squeeze the water in the fruit and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com