Weather-proof bi-component silane modified polyether sealant and preparation method thereof

A silane-modified polyether, two-component technology, applied in the field of sealants, can solve problems such as intolerance to extraction, easy volatilization, and easy migration, and achieve the effects of good extraction resistance, low hygroscopicity, and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

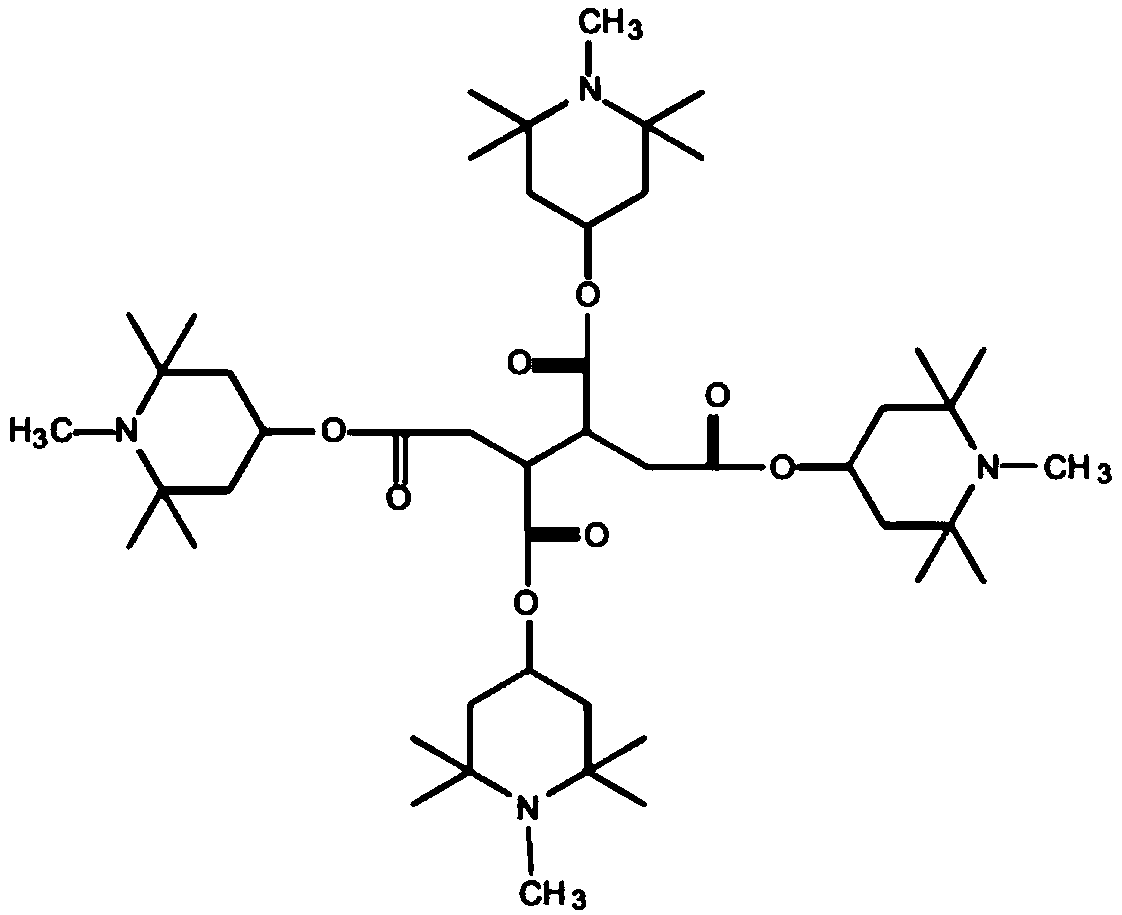

Method used

Image

Examples

Embodiment 1

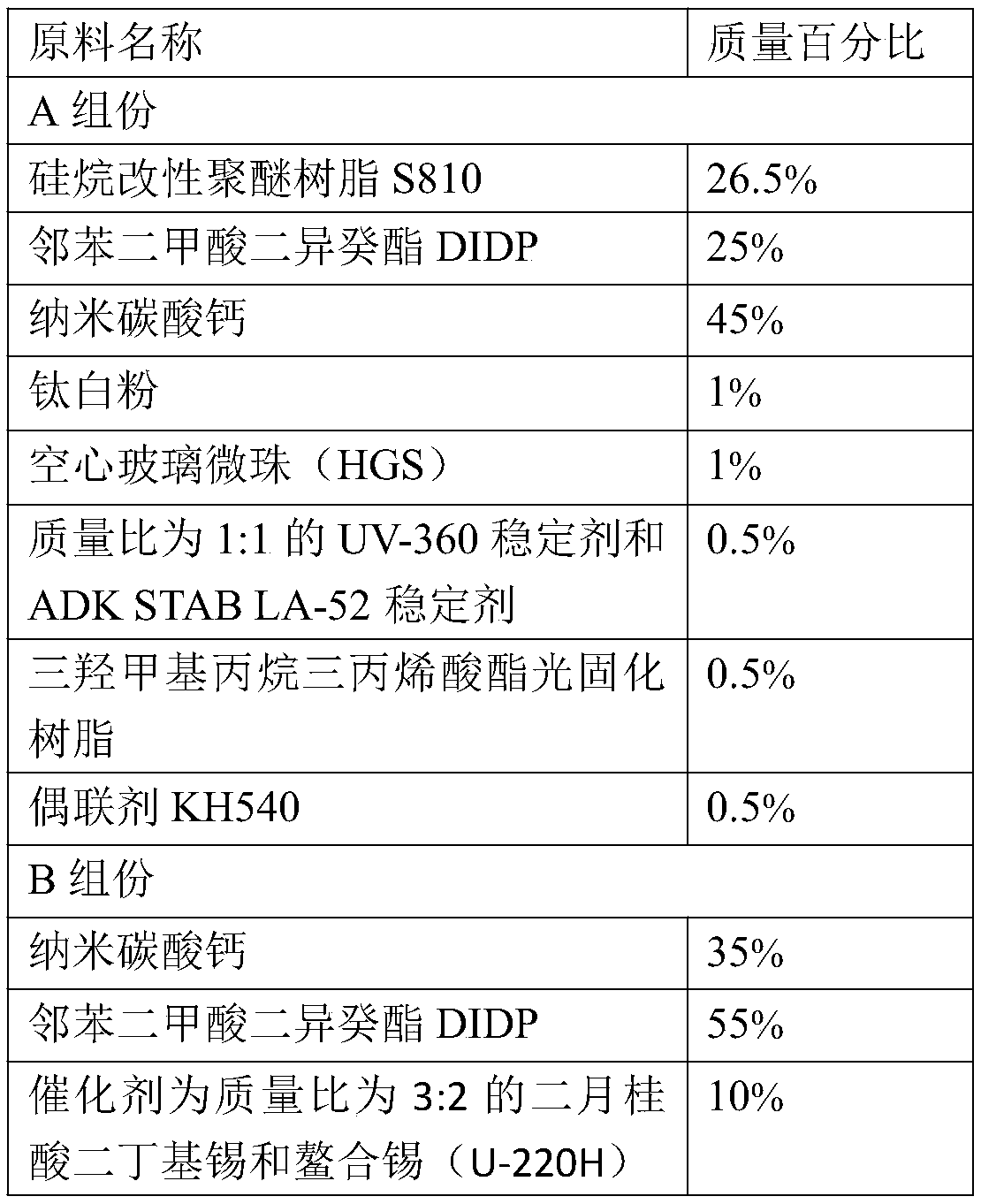

[0033] The two-component silane-modified polyether sealant in this example is formed by mixing component A and component B at a mass ratio of 10:1, wherein component A and component B are prepared from the following mass percentage raw materials:

[0034]

[0035] The preparation method of sealant, comprises the steps:

[0036] (1) Preparation of component A: Weigh the raw materials according to the above proportions, add silane-modified polyether resin, plasticizer, nano-calcium carbonate, titanium dioxide, hollow resin and composite light stabilizer into the high-speed disperser, and mix the materials Raise the temperature to 85°C, and stir for 2.5 hours under a vacuum of 0.090±0.005MPa to obtain the mixed material; when the temperature of the mixed material is lowered to below 45°C, add light-curable resin and coupling agent, stir for 30 minutes, cool down and discharge the material for packaging, and obtain Group A product;

[0037](2) Preparation of component B: Weigh...

Embodiment 2

[0040] The two-component silane-modified polyether sealant in this example is formed by mixing component A and component B at a mass ratio of 10:1, wherein component A and component B are prepared from the following mass percentage raw materials:

[0041]

[0042]

[0043] The preparation method of sealant, comprises the steps:

[0044] (1) Preparation of component A: Weigh the raw materials according to the above proportions, add silane-modified polyether resin, plasticizer, nano-calcium carbonate, titanium dioxide, hollow resin and composite light stabilizer into the high-speed disperser, and mix the materials Raise the temperature to 90°C, and stir for 2 hours under a vacuum of 0.090±0.005MPa to obtain the mixed material; when the temperature of the mixed material is lowered to below 45°C, add light-curable resin and coupling agent, stir for 15 minutes, cool down and discharge the material for packaging, and obtain component A product;

[0045] (2) Preparation of com...

Embodiment 3

[0048] The two-component silane-modified polyether sealant in this example is formed by mixing component A and component B at a mass ratio of 10:1, wherein component A and component B are prepared from the following mass percentage raw materials:

[0049]

[0050]

[0051] The preparation method of sealant, comprises the steps:

[0052] (1) Preparation of component A: Weigh the raw materials according to the above proportions, add silane-modified polyether resin, plasticizer, nano-calcium carbonate, titanium dioxide, hollow resin and composite light stabilizer into the high-speed disperser, and mix the materials Raise the temperature to 100°C, and stir for 1.5 hours under a vacuum of 0.090±0.005MPa to obtain the mixed material; when the temperature of the mixed material is lowered to below 45°C, add light-curable resin and coupling agent, stir for 30 minutes, cool down and discharge the material for packaging, and obtain Group A product;

[0053] (2) Preparation of comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com