A kind of flame-retardant silane-modified polyether sealant and preparation method thereof

A silane-modified polyether and sealant technology, which is applied in the field of sealants, can solve the problems of easy moisture absorption of flame retardants, low production efficiency, and reduced mechanical properties of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

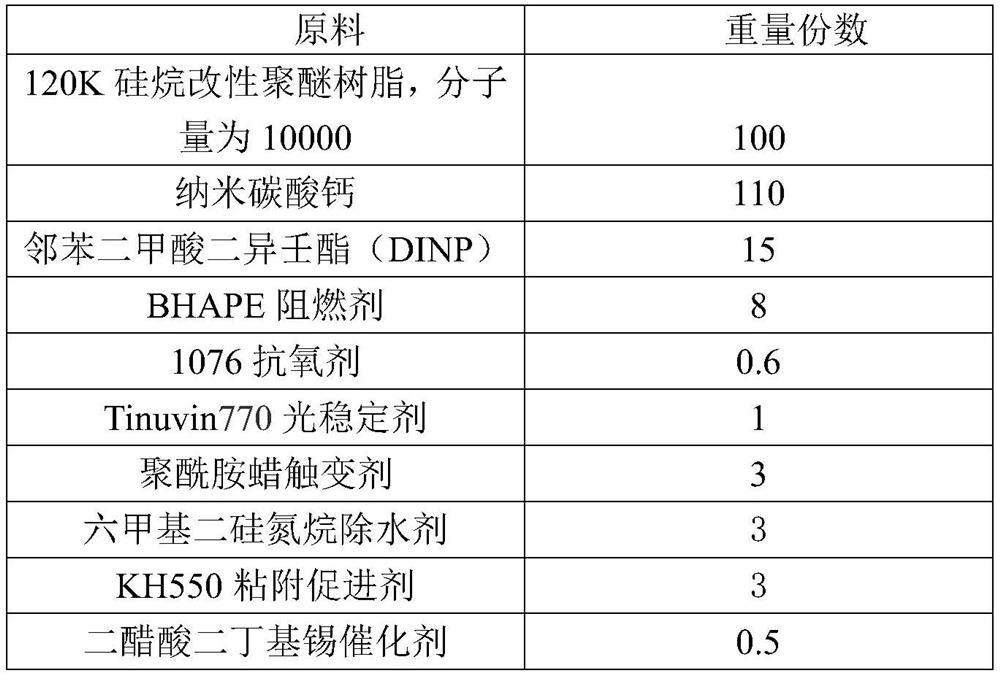

[0035] The flame-retardant silane-modified polyether sealant of this embodiment is formed by mixing the following raw materials in parts by weight:

[0036]

[0037] The preparation method of described silane modified polyether sealant comprises the steps:

[0038] (1) Weigh each raw material according to the above ratio, add silane-modified polyether resin, plasticizer and flame retardant to a high-speed mixer at room temperature, and stir and mix at a speed of 25 rpm for 5 minutes;

[0039](2) Then add nano-calcium carbonate, antioxidant and thixotropic agent, stir at 25rpm for 8min, switch to high-speed stirring at 40rpm, then raise the temperature to 100°C, and turn on the vacuum when the temperature is reached. Under vacuum conditions, the vacuum degree is 0.09±0.05 Continue to stir for 1h under MPa to obtain a mixture;

[0040] (3) Cool the above mixture to below 40°C, then add light stabilizer, water remover, adhesion promoter and catalyst, and continue to stir at 4...

Embodiment 2

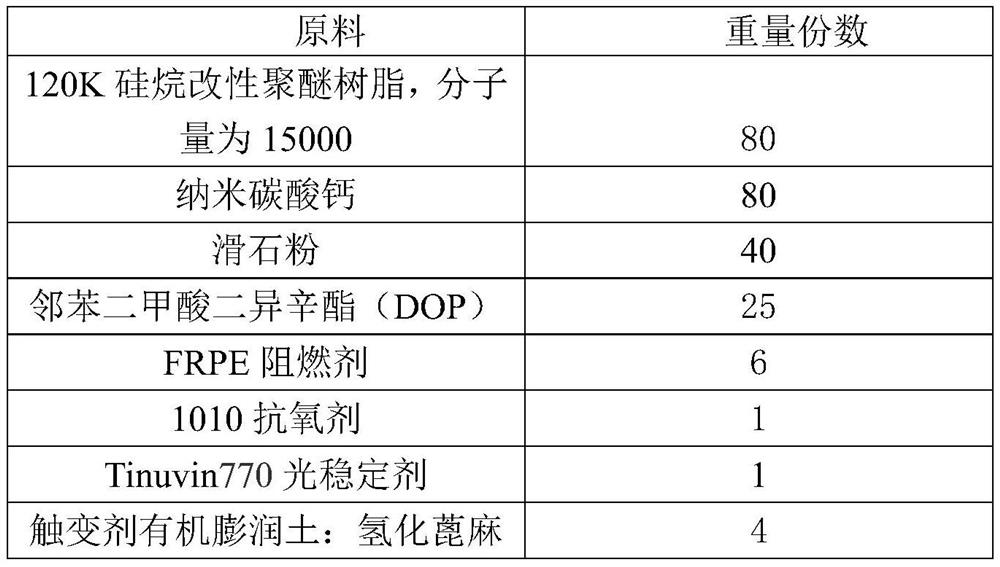

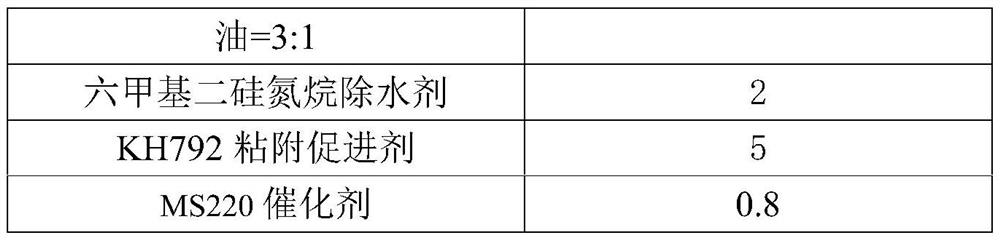

[0043] The flame-retardant silane-modified polyether sealant of this embodiment is formed by mixing the following raw materials in parts by weight:

[0044]

[0045]

[0046] The preparation method of described silane modified polyether sealant comprises the steps:

[0047] (1) Weigh each raw material according to the above ratio, add silane-modified polyether resin, plasticizer and flame retardant to a high-speed mixer at room temperature, and stir and mix at a speed of 30 rpm for 8 minutes;

[0048] (2) Then add nano-calcium carbonate, antioxidant and thixotropic agent, stir at 30rpm for 5min, switch to high-speed stirring at 40rpm, then heat up to 110°C, and turn on the vacuum when the temperature is reached. Under vacuum conditions, the vacuum degree is 0.09±0.05 Continue stirring for 1.5h under MPa to obtain a mixture;

[0049] (3) Cool the above mixture to below 40°C, then add light stabilizer, water remover, adhesion promoter and catalyst, and continue to stir at...

Embodiment 3

[0052] The flame-retardant silane-modified polyether sealant of this embodiment is formed by mixing the following raw materials in parts by weight:

[0053]

[0054] The preparation method of described silane modified polyether sealant comprises the steps:

[0055] (1) Weigh each raw material according to the above ratio, add silane-modified polyether resin, plasticizer and flame retardant to a high-speed mixer at room temperature, and stir and mix at a speed of 20 rpm for 10 minutes;

[0056] (2) Then add nano-calcium carbonate, antioxidant and thixotropic agent, stir at 20rpm for 10min, switch to high-speed stirring at 50rpm, then raise the temperature to 120°C, and turn on the vacuum when the temperature is reached. Under vacuum conditions, the vacuum degree is 0.09±0.05 Continue stirring for 2h under MPa to obtain a mixture;

[0057] (3) Cool the above mixture to below 40°C, then add light stabilizer, water remover, adhesion promoter and catalyst, and continue to stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com