Novel wide-temperature-range lubricating oil and preparation method thereof

A lubricating oil and wide temperature range technology, applied in lubricating compositions, petroleum industry, etc., can solve problems such as insufficient fluidity of lubricating oil, poor low-temperature startability of vehicles, and reduced lubricating performance, and achieve good high oxidation stability and low-temperature flow Excellent properties, good kinematic viscosity, and excellent lubricating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

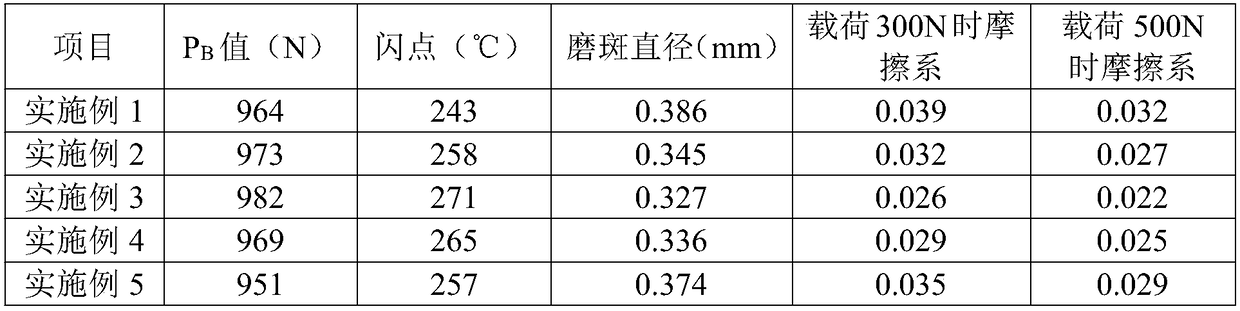

Examples

Embodiment 1

[0023] Example 1 Preparation of novel wide temperature range lubricating oil:

[0024] At a stirring speed of 800 rev / min, add 0.8 parts by weight of lubricant, 0.05 parts by weight of N-(2,3-dichloro-6-amino-benzyl) ethyl glycine successively to 75 parts by weight of base oil, 0.05 parts by weight of triethanolamine, mixed uniformly, heated up to 40° C., then added in sequence with 0.5 parts by weight of sodium benzoate and 0.05 parts by weight of chlorobenzene, mixed uniformly to obtain lubricating oil.

[0025] The base oil is a mixture of dipentaerythritol ester and diester adipate, the mass ratio of which is 1:4, and the lubricant is a mixture of glycerol trihydroxystearate and methyl silicone oil, wherein glycerol trihydroxystearate and The mass ratio of methyl silicone oil is 1:1.5.

Embodiment 2

[0026] Embodiment 2 Preparation of novel wide temperature range lubricating oil:

[0027] At a stirring speed of 800 rev / min, add 1.5 parts by weight of lubricant, 0.2 parts by weight of N-(2,3-dichloro-6-amino-benzyl) glycine ethyl ester, 0.1 part by weight of triethanolamine was mixed uniformly, and the temperature was raised to 45° C., followed by adding 1.0 part by weight of sodium benzoate and 0.08 part by weight of chlorobenzene, and mixed uniformly to obtain lubricating oil.

[0028] The base oil is dipentaerythritol ester, the lubricant is a mixture of glycerol trihydroxystearate and ethyl silicone oil, and the mass ratio of glycerol trihydroxystearate to ethyl silicone oil is 1:2.5.

Embodiment 3

[0029] Example 3 Preparation of novel wide temperature range lubricating oil:

[0030] At a stirring speed of 1000 rev / min, add 2.0 parts by weight of lubricant, 0.3 parts by weight of N-(2,3-dichloro-6-amino-benzyl) glycine ethyl ester, 0.9 parts by weight of triethanolamine, mixed uniformly, heated up to 40°C, then added 1.2 parts by weight of sodium benzoate, 0.1 parts by weight of chlorobenzene, mixed uniformly, to obtain lubricating oil.

[0031] The base oil is a mixture of pentaerythritol ester and trimethylolpropane oleate, the mass ratio of which is 1:2, and the lubricant is a mixture of glycerol trihydroxystearate and benzyl silicone oil, of which glycerol trihydroxystearate The mass ratio of acid ester to benzyl silicone oil is 1:2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com