Optical phased array chip transmitter based on metal slit waveguides

An optical phased array and slotted waveguide technology, applied in the field of integrated optics, can solve the problems of small beam scanning angle, large waveguide spacing, weak light wave mode field constraints, etc., achieve large beam deflection angle, small crosstalk, and increase deflection angle range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

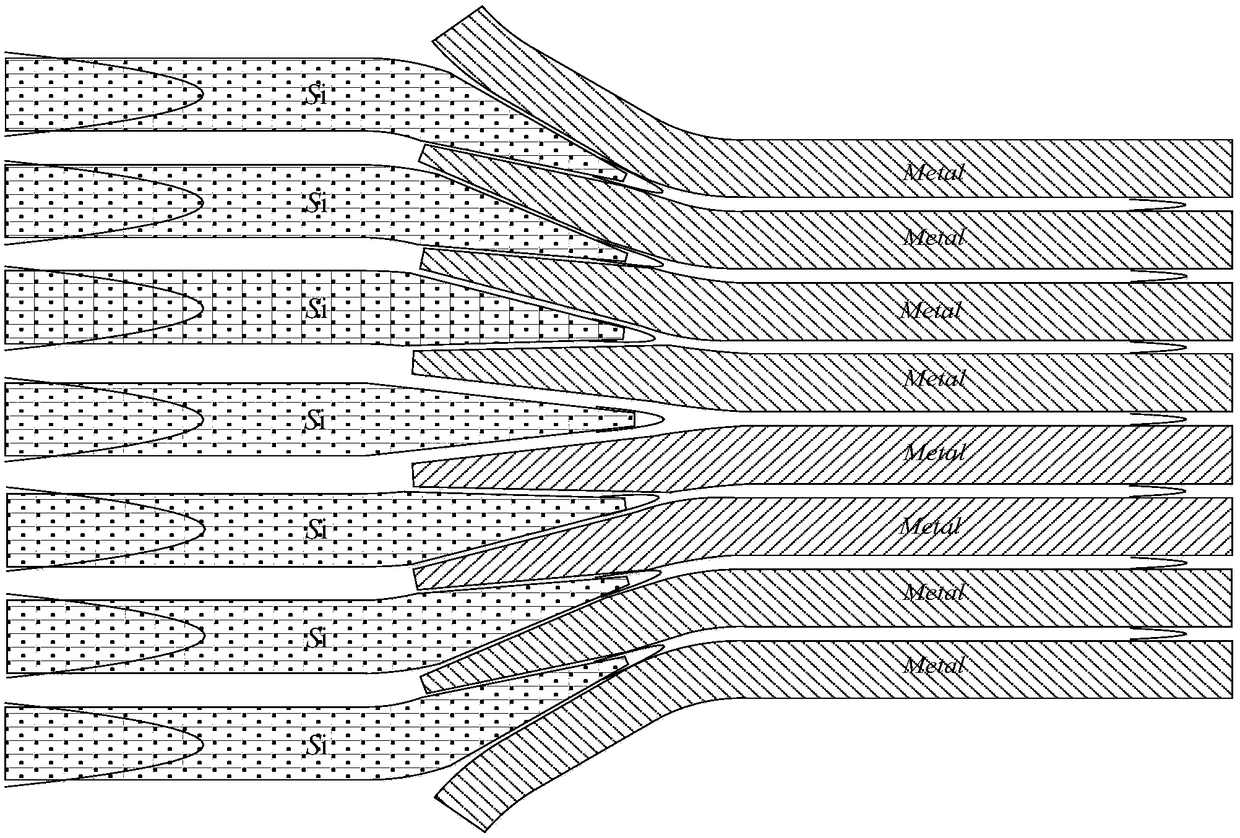

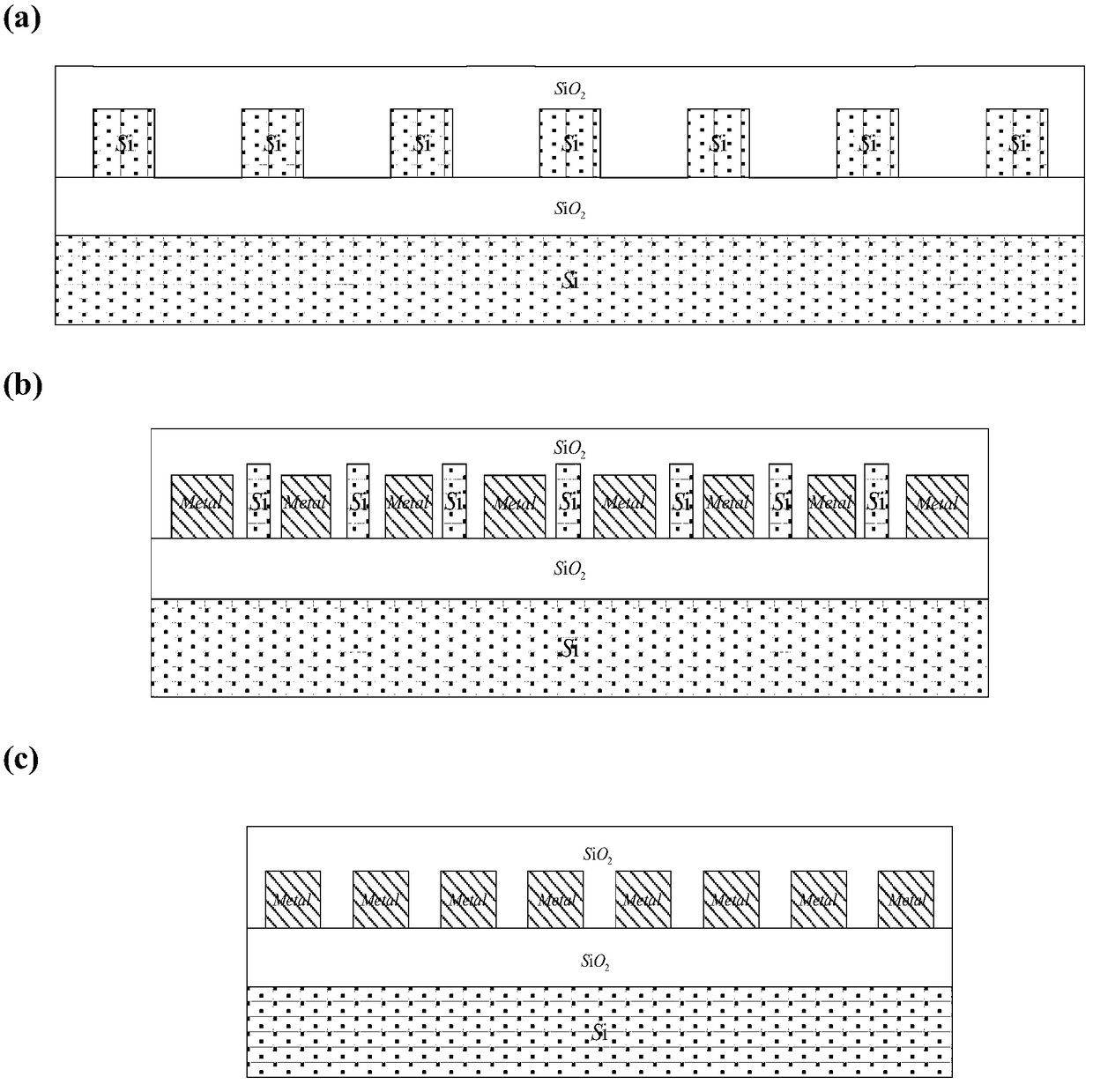

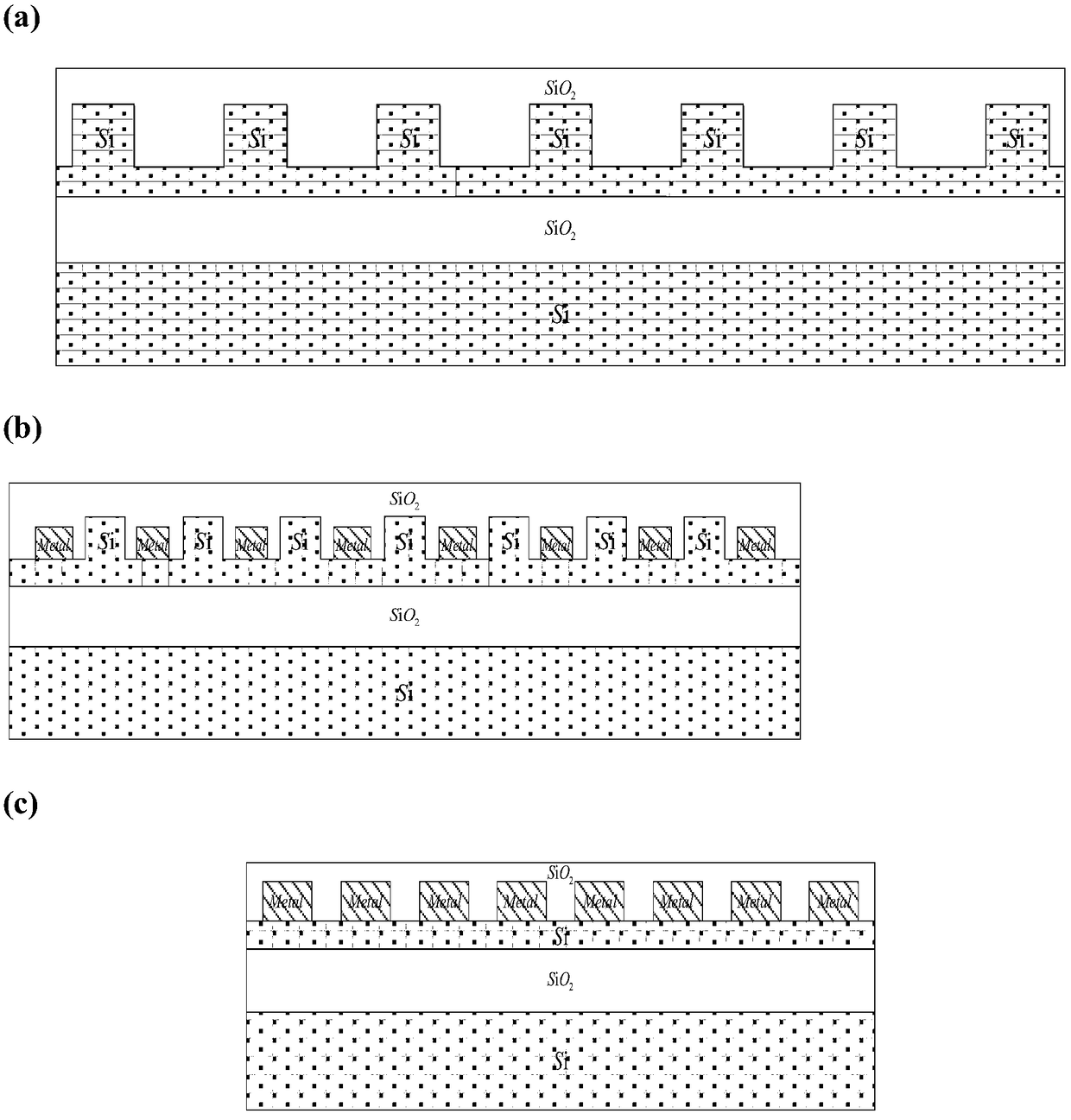

[0023] figure 2 and image 3The thickness of the middle and lower cladding layers is 2μm, the thickness of the upper cladding layer is 1.5μm, the thickness of the silicon waveguide layer is 220nm, the width of the left waveguide layer is 500nm, and the center interval of the waveguide is 5μm. Among them, image 3 The thickness of the slab layer of the middle silicon waveguide is 90nm, and the thickness of the convex part is 130nm. figure 1 The distance between the edges of adjacent metal plasmonic slot waveguides at the position of the dotted line on the right side of the center is 100nm, figure 2 The thickness of the metal plasmonic slot waveguide is 170nm, image 3 The thickness of the metal plasmonic slot waveguide is 90nm. The distance between the edges of adjacent waveguides in the interspersed part of the silicon waveguide and the metal plasma slot waveguide is 50nm, the minimum width of the tapered part at the far right end of the silicon waveguide is 80nm, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com