Soluble micro needle with anti-acne effect and preparation method thereof

A soluble, acne-removing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

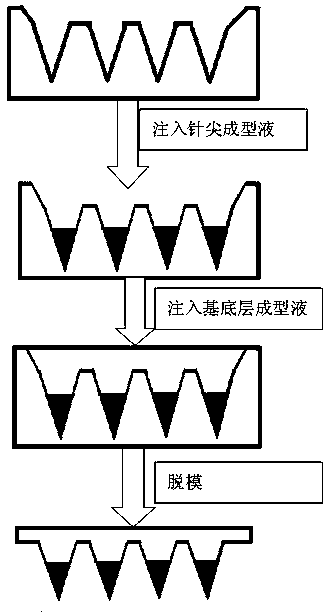

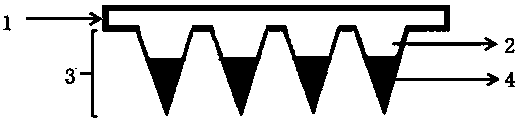

Method used

Image

Examples

Embodiment 1

[0061] A method for preparing a soluble microneedle with anti-acne effect, characterized in that it comprises the following steps:

[0062] A. Weigh 800 g sodium hyaluronate at 8%, 100 g papain at 1%, 3000 g acne-removing composition at 30%, and 6100 g excipients at 61% for subsequent use; 100 g of chlorogenic acid, 200 g of licochalcone A, 1000 g of heparin sodium, and 1500 g of epigallocatechin gallate were weighed to form an acne-removing composition at a ratio of 1:2:10:15. Weigh 1000 g mannitol, 1000 g yeast dextran, 2000 g carboxymethylcellulose and 1000 g glycogen to form excipients respectively in a mass ratio of 1:1:2:1;

[0063] B. Mix and dissolve the acne-removing composition taken in step A with 14 kg of distilled water to obtain an aqueous solution of the acne-removing composition;

[0064] C. Dissolve the sodium hyaluronate weighed in step A in 79.2 kg distilled water to prepare a sodium hyaluronate aqueous solution with a mass fraction of 1%, then add the papa...

Embodiment 2

[0073] A method for preparing a soluble microneedle with anti-acne effect, characterized in that it comprises the following steps:

[0074] A. Weigh 10 g sodium hyaluronate at 10%, 3 g papain at 3%, 35 g acne-removing composition at 35%, and 52 g excipients at 52% for subsequent use; 15 g of chlorogenic acid, 45 g of licochalcone A, 180 g of heparin sodium, and 270 g of epigallocatechin gallate were weighed to form an acne-removing composition at a ratio of 1:3:12:18. Weigh 20 g mannitol, 40 g yeast dextran, 80 g carboxymethyl cellulose and 60 g glycogen to form the excipient respectively in a mass ratio of 1:2:4:3;

[0075] B. Mix and dissolve the acne-removing composition taken in step A with 500 g of distilled water to obtain an aqueous solution of the acne-removing composition;

[0076] C. Dissolve the sodium hyaluronate weighed in step A in 490 g distilled water to prepare a sodium hyaluronate aqueous solution with a mass fraction of 2%, then add the papain weighed in step...

Embodiment 3

[0085] A method for preparing a soluble microneedle with anti-acne effect, characterized in that it comprises the following steps:

[0086] A, take by weight 14% sodium hyaluronate 140g, 4% by weight 40g papain, 38% by weight 380g acne composition, 44% by weight by weight 440g excipient for subsequent use; 100 g of chlorogenic acid, 400 g of licochalcone A, 1500 g of heparin sodium, and 2500 g of epigallocatechin gallate were weighed to form an acne-removing composition at a ratio of 1:4:15:25. Weigh 100 g mannitol, 200 g yeast dextran, 500 g carboxymethyl cellulose and 400 g glycogen to form the excipient respectively in a mass ratio of 1:2:5:4;

[0087] B. Mix and dissolve the acne-removing composition taken in step A with 5000 g of distilled water to obtain an aqueous solution of the acne-removing composition;

[0088] C. Dissolve the sodium hyaluronate weighed in step A in 9193 g distilled water to prepare a sodium hyaluronate aqueous solution with a mass fraction of 1.5%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com