Processing technology of rhizoma typhonii and product obtained through processing technology

A technology for processing Radix Aconiti, which is applied in the processing technology of Radix Aconiti and its products. It can solve problems such as excessive intake of aluminum ions, damage to brain thinking and nerve function, moldy deterioration, etc., so as to ensure the appearance and internal quality, and avoid The effect of spoilage and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

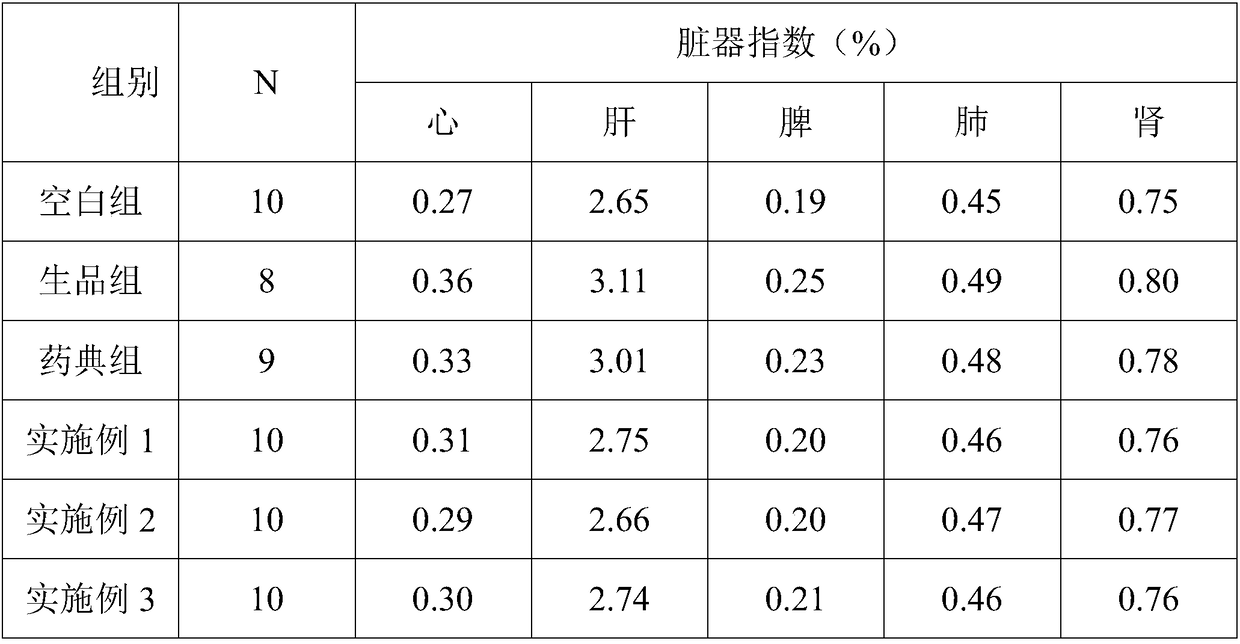

Examples

Embodiment 1

[0044] A process for preparing Aconite Radix, comprising the steps of:

[0045] Cleaning steps: take the white aconite and wash it, drain the surface water, and control the water content of the white aconite to 7%;

[0046] Steps of vacuuming: put it into a container, push it into the medicine steaming machine or medicine moistening machine, seal it, and vacuumize it to -0.03Mpa;

[0047] Vacuum warming and moistening steps: Keep a vacuum of -0.03Mpa in the medicine steaming machine or medicine moistening machine, and pass in hot steam at a temperature of 85°C. After the hot steam is introduced, let the medicine steaming machine or medicine moistening machine The vacuum pressure gradually rises, and returns to normal pressure within 1.5 hours, so that the white monkshood can be warmed;

[0048] Steps for slicing: Take the Radix Aconiti Radix officinalis from the medicine steaming machine or medicine moistening machine, and cut into thin slices with a thickness of 2-3mm.

Embodiment 2

[0050] A process for preparing Aconite Radix, comprising the steps of:

[0051] Cleaning steps: take the white aconite and wash it, drain the surface water, and control the water content of the white aconite to 9%;

[0052] Steps of vacuuming: put it into a container, push it into the medicine steaming machine or medicine moistening machine, seal it, and vacuumize it to -0.04Mpa;

[0053] Vacuum warming and moistening steps: Keep a vacuum of -0.04Mpa in the medicine steaming machine or medicine moistening machine, and feed hot steam at a temperature of 95°C. After the hot steam fills the whole medicine steaming machine or medicine moistening machine, let The vacuum pressure in the medicine steaming machine or medicine moistening machine rises gradually, and returns to normal pressure within 2 hours, so that the white aconite is warmed;

[0054] Steps for slicing: Take the Radix Aconiti Radix officinalis from the medicine steaming machine or medicine moistening machine, and cut ...

Embodiment 3

[0056] A process for preparing Aconite Radix, comprising the steps of:

[0057] Cleaning steps: take the Radix Aconitie and wash it, drain the surface water, and control the water content of the Radix Abdominale to 11%;

[0058] Steps of vacuuming: put it into a container, push it into the medicine steaming machine or medicine moistening machine, seal it, and vacuumize it to -0.05Mpa;

[0059] Vacuum warming and moistening steps: Keep a vacuum of -0.05Mpa in the medicine steaming machine or medicine moistening machine, feed hot steam at a temperature of 95°C, and let the medicine steaming machine or medicine moistening machine The vacuum pressure gradually rises, and returns to normal pressure within 2.5 hours, so that the white monkshood can be warmed;

[0060] Steps for slicing: Take the Radix Aconiti Radix officinalis from the medicine steaming machine or medicine moistening machine, and cut into thin slices with a thickness of 2-3mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com