Thorium-doped diatomite supported p-toluenesulfonic acid catalyst, and preparation method and application thereof

A technology of p-toluenesulfonic acid and diatomaceous earth, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of large catalyst consumption and difficult recovery. , to reduce external energy consumption, improve dehydration performance, and achieve good low-temperature activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

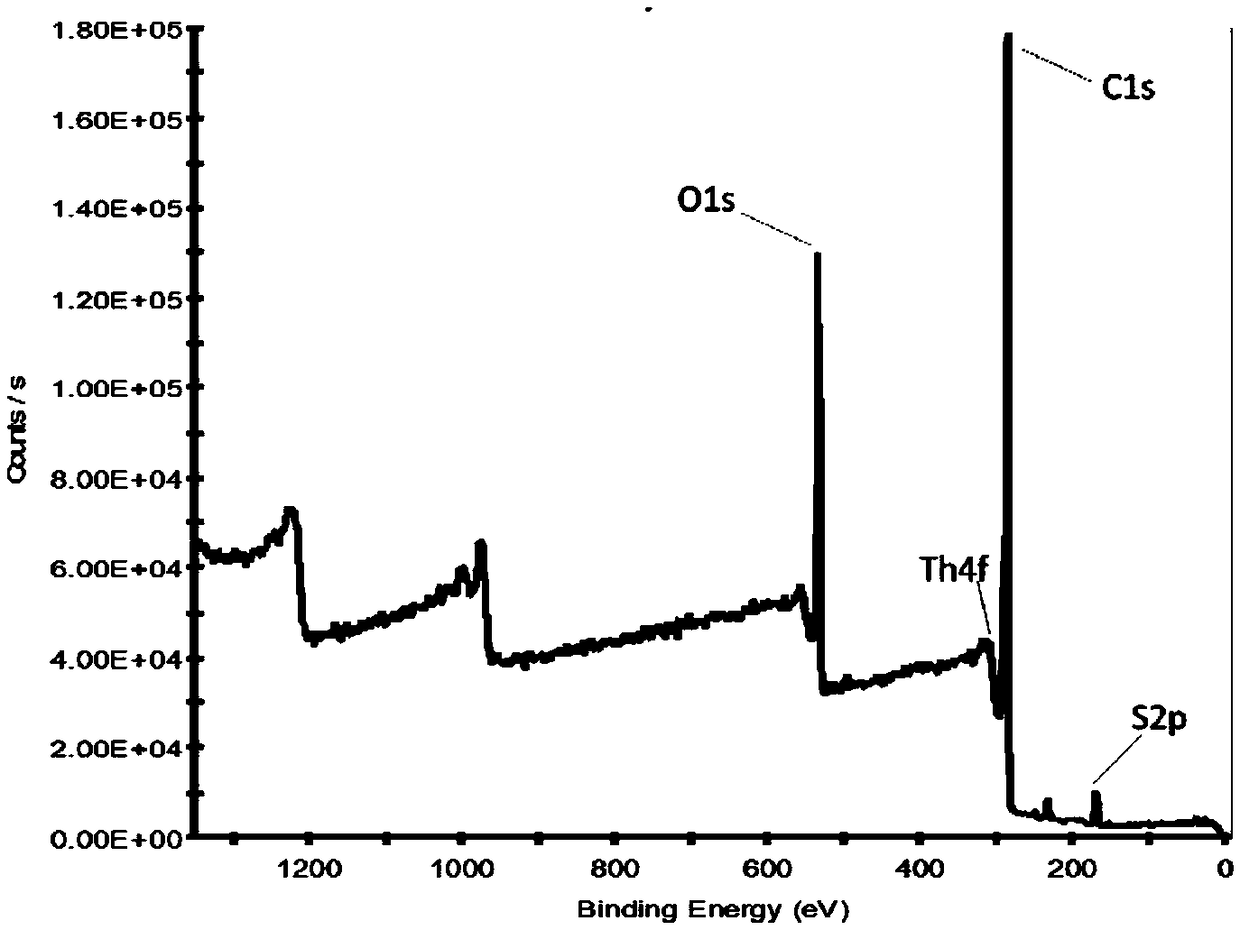

[0037] (1) Preparation of thorium-doped diatomite-supported p-toluenesulfonic acid catalyst

[0038] Take a certain amount of diatomaceous earth and soak it in dilute nitric acid with a mass fraction of 10% for 24 hours, wash it with distilled water and drain it, and then activate it at 25°C for 2 hours.

[0039] Take 10 g of the diatomite obtained in the previous step, pour it into 60 mL of 20% p-toluenesulfonic acid solution, and let it stand for 30 h.

[0040] The mixed solution from the previous step was filtered and dried at 25° C. for 5 h to obtain a diatomaceous earth-supported p-toluenesulfonic acid catalyst.

[0041] Take 50mL of thorium nitrate solution with a thorium ion concentration of 0.1g / L, impregnate 0.5g of the catalyst obtained in the previous step into it, disperse evenly through ultrasonication, and then evaporate the solution to dryness at 25°C.

[0042] Place the sample obtained in the previous step in a muffle furnace, heat up to 300°C at a rate of 0.1...

Embodiment 2

[0047] (1) Preparation of thorium-doped diatomite-supported p-toluenesulfonic acid catalyst

[0048] Take a certain amount of diatomaceous earth and soak it in dilute nitric acid with a mass fraction of 11% for 22 hours, wash it with distilled water and drain it, and then activate it at 75°C for 1.5 hours.

[0049] Take 12g of the diatomaceous earth obtained in the previous step, pour it into 75mL of 25% p-toluenesulfonic acid solution, and let it stand for 32h.

[0050] The mixed solution from the previous step was filtered and dried at 75° C. for 4 hours to obtain a diatomaceous earth-supported p-toluenesulfonic acid catalyst.

[0051] Take 200mL of thorium nitrate solution with a thorium ion concentration of 1.5g / L, impregnate 2g of the catalyst obtained in the previous step in it, disperse evenly through ultrasonication, and then evaporate the solution to dryness at 90°C.

[0052] Place the sample obtained in the previous step in a muffle furnace, raise the temperature to...

Embodiment 3

[0057] Take a certain amount of diatomite and soak it in dilute nitric acid with a mass fraction of 12% for 20 hours, wash it with distilled water and drain it, and then activate it at 120°C for 1 hour.

[0058] Take 15g of the diatomite obtained in the previous step, pour it into 90mL of 30% p-toluenesulfonic acid solution, and let it stand for 35h.

[0059] The mixed solution from the previous step was filtered and dried at 110° C. for 3 hours to obtain a diatomaceous earth-supported p-toluenesulfonic acid catalyst.

[0060] Take 400mL of thorium nitrate solution with a thorium ion concentration of 3g / L, impregnate 4g of the catalyst obtained in the previous step in it, disperse evenly through ultrasonication, and evaporate the solution to dryness at 150°C.

[0061] Place the sample obtained in the previous step in a muffle furnace, heat up to 1100°C at a rate of 10°C / min, and calcinate at this temperature for 5 hours to obtain a diatomite-supported p-toluenesulfonic acid ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com