Precious metal-doped titanium dioxide nanometer composite material and preparation method thereof

A titanium dioxide and composite material technology, applied in the field of nanomaterials, can solve the problems of less than 10% solar energy utilization rate, affecting the photocatalytic performance of materials, increasing oxygen vacancies, etc., to inhibit particle growth and condensation process, suitable for large-scale production, The effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

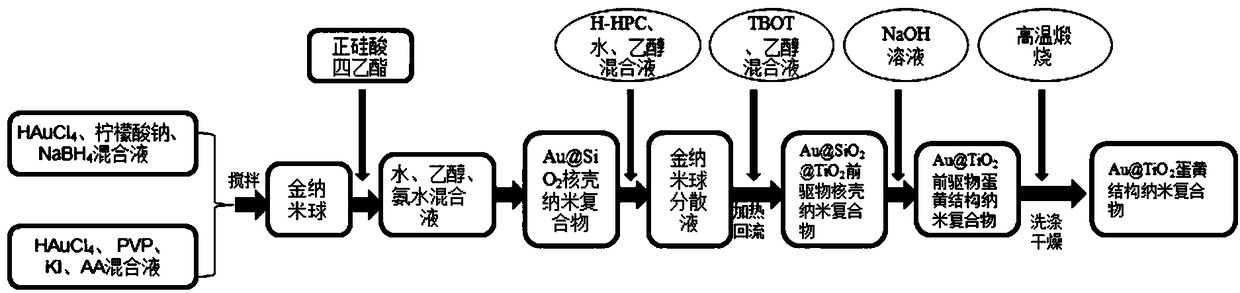

[0033] refer to figure 1 , the present embodiment provides a method for preparing a noble metal-doped titanium dioxide composite material, comprising the following steps:

[0034] S1. Preparation of gold nanospheres by seed method.

[0035] Specifically, step S1 includes the following sub-steps:

[0036] S11, the chloroauric acid solution (HAuCl 4 ) and 0.55 mL of sodium citrate solution with a concentration of 5 mmol / L were added to 20 mL of ultrapure water, stirred for 5 min, and mixed uniformly to obtain solution A.

[0037] S12, the sodium borohydride solution (NaBH 4 ) into solution A, vigorously stirred for 2 h, and mixed uniformly to obtain solution B.

[0038] Wherein, during this stirring process, the HAuCl in solution A 4 solution as gold source, NaBH 4 The solution mainly acts as a reducing agent with HAuCl 4 The solution undergoes a reaction to reduce metallic gold (ie gold seeds). During the whole reaction process, the sodium citrate solution in the soluti...

Embodiment 2

[0073] This embodiment provides a method for preparing a noble metal-doped titanium dioxide composite material, comprising the following steps:

[0074] S1. Preparation of gold nanospheres by seed method.

[0075] Specifically, step S1 includes the following sub-steps:

[0076] S11, 0.25 mL of HAuCl with a concentration of 3 mmol / L 4 Solution and 0.35 mL of sodium citrate solution with a concentration of 4 mmol / L were added to 12 mL of ultrapure water, stirred for 1 min, and mixed uniformly to obtain solution A.

[0077] S12, 0.25 mL of NaBH with a concentration of 0.01 mol / L 4 The solution was added to solution A, stirred vigorously for 1 h, and mixed uniformly to obtain solution B.

[0078] S13, 25mL of HAuCl with a concentration of 3.5mmol / L 4 solution, 5.2mL of PVP with a concentration of 4%wt, 2.8mL of KI solution with a concentration of 0.1mol / L and 3.5mL of AA solution with a concentration of 0.01mol / L were dissolved in 75mL of ultrapure water, vigorously stirred an...

Embodiment 3

[0098] This embodiment provides a method for preparing a noble metal-doped titanium dioxide composite material, comprising the following steps:

[0099] S1. Preparation of gold nanospheres by seed method.

[0100] Specifically, step S1 includes the following sub-steps:

[0101] S11, 0.65 mL of HAuCl with a concentration of 6 mmol / L 4 solution and 0.75 mL of sodium citrate solution with a concentration of 7 mmol / L were added to 27 mL of ultrapure water, stirred for 10 min, and mixed uniformly to obtain solution A.

[0102] S12, 0.75 mL of NaBH with a concentration of 0.2 mol / L 4 The solution was added to solution A, stirred vigorously for 3 h, and mixed uniformly to obtain solution B.

[0103] S13, the 75mL concentration is 7mmol / L HAuCl 4 solution, 13mL of PVP with a concentration of 7%wt, 6.5mL of KI solution with a concentration of 0.4mol / L and 7.2mL of AA solution with a concentration of 0.15mol / L were dissolved in 148mL of ultrapure water, vigorously stirred and mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com