Non-noble metal catalyst and preparation method

A non-precious metal and catalyst technology, which is applied in the field of non-precious metal catalysts and their preparation, can solve the problems of large particle size of non-precious metal particles, reduce the performance of non-precious metals, and easily agglomerate, so as to improve catalytic activity, inhibit agglomeration growth, and improve catalytic performance. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention provides a kind of preparation method of non-precious metal catalyst, comprises the following steps:

[0023] mixing an ethanol-water solvent, a carrier material and a non-noble metal salt to obtain a non-noble metal salt dispersion;

[0024] The non-noble metal salt dispersion liquid is mixed with sodium borohydride solution, a reduction reaction occurs, and the reduction product is washed with water to obtain a non-noble metal catalyst.

[0025] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0026] The present invention mixes ethanol-water solvent, carrier material and non-precious metal salt to obtain non-precious metal salt dispersion; in the present invention, the volume ratio of ethanol and water in the ethanol-water solvent is preferably (2~4):( 1-3), more preferably (2.5-3.5): (1.5-2.5), most preferably (2.8-3.2): (1.8-2.2).

[0027] I...

Embodiment 1

[0052] Mix ethanol and distilled water in a volume ratio of 3:2 to obtain an ethanol-water solvent;

[0053] Dissolve 0.1 g of carbon nanospheres into 50 mL of alcohol-water solvent, ultrasonicate for 60 min, and stir for 30 min to disperse to obtain a mixed solution;

[0054] Dissolve 1 mmol of cobalt acetate in the above mixed solution, sonicate for 30 minutes, and stir at 5°C for 1 hour to obtain a mixed solution of cobalt acetate;

[0055] Add 20 mL of sodium borohydride solution with a concentration of 0.2 mol / L to the cobalt acetate mixed solution, and continue stirring at 5° C. for 10 min until it is completely reduced. Simultaneous precipitation;

[0056] Suction filter the above product, and then wash with distilled water for 3-4 times, the by-product sodium metaborate is dissolved in water and washed off to obtain the washed product;

[0057] The above-mentioned washed product was vacuum freeze-dried at -45°C to obtain a C@Co catalyst.

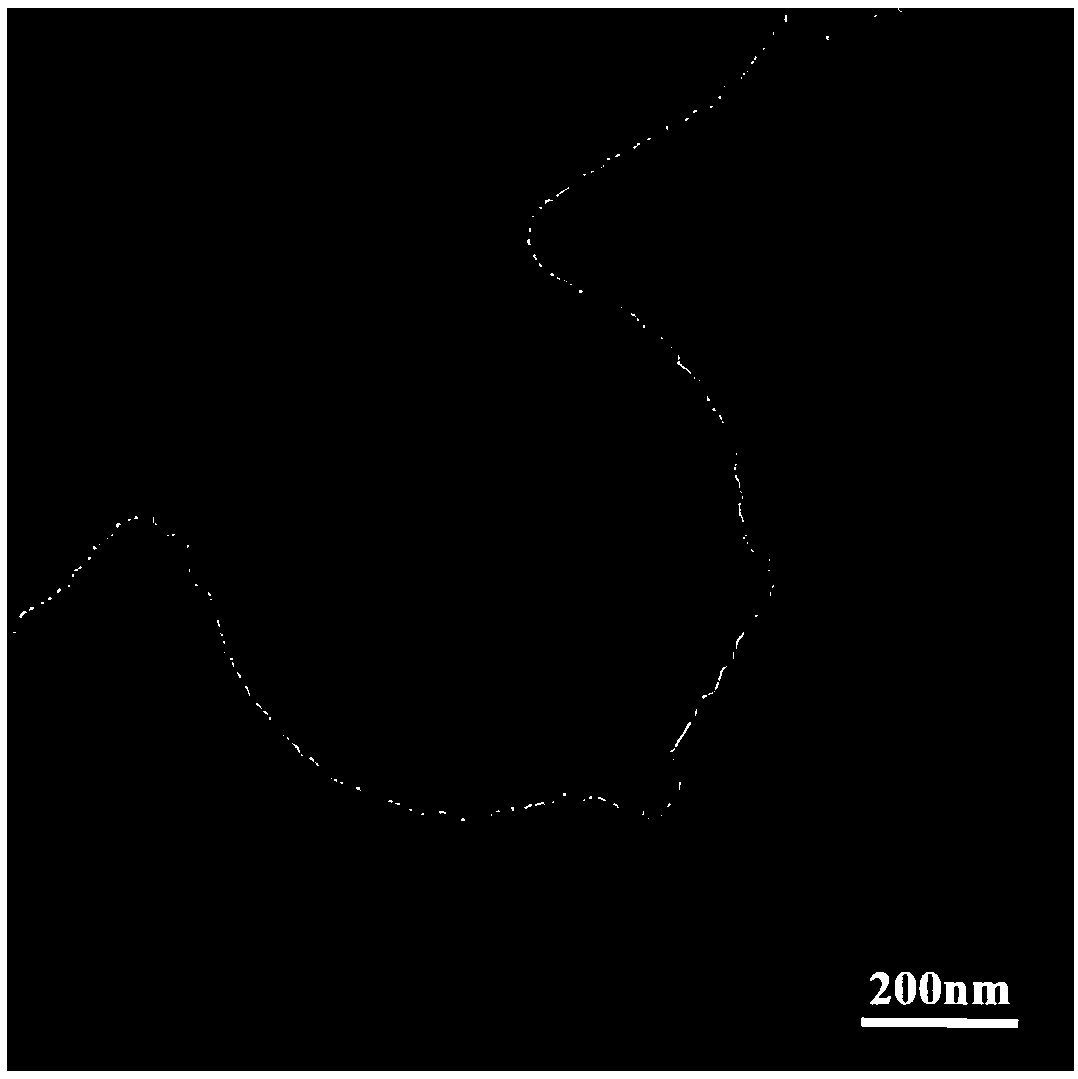

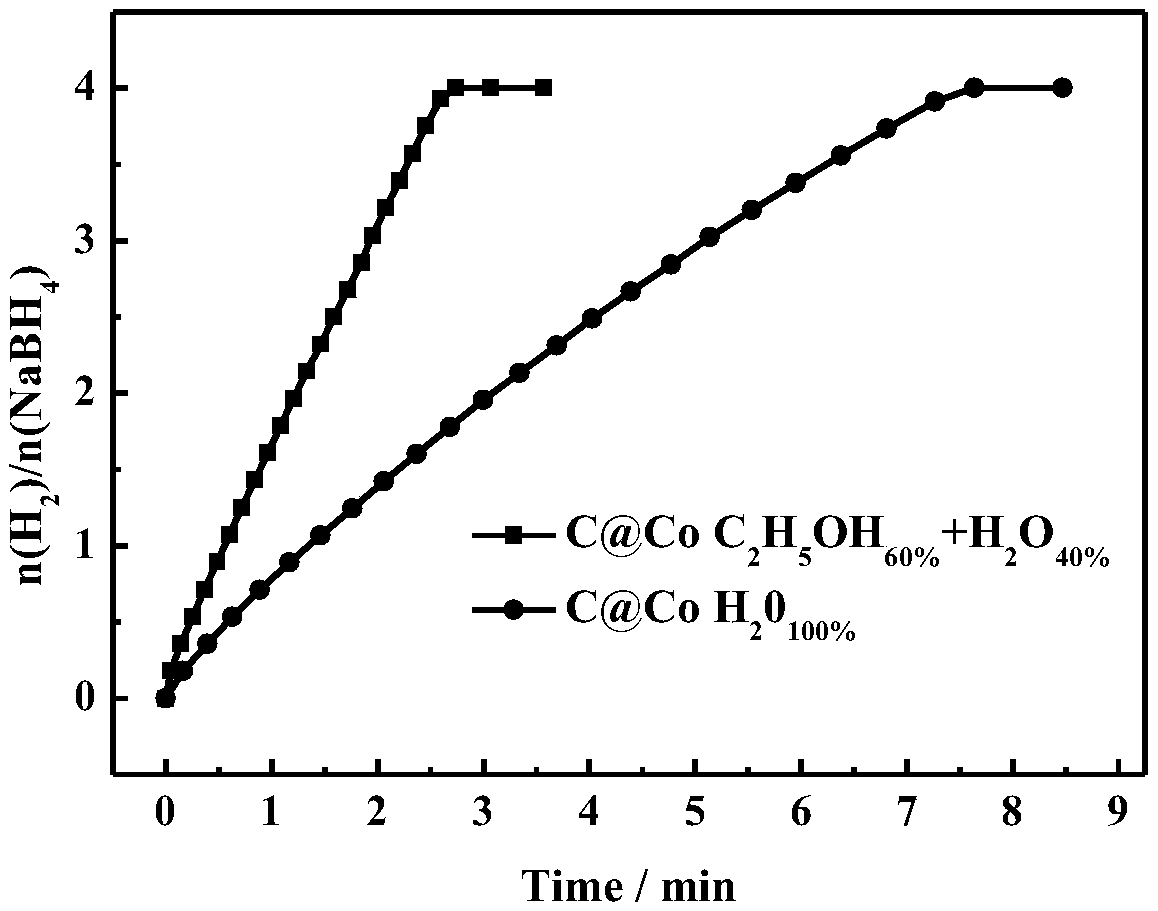

[0058] figure 1 The trans...

Embodiment 2

[0061] Mix ethanol and distilled water at a volume ratio of 1:1 to obtain an ethanol-water solvent;

[0062] Dissolve 0.1 g of graphene oxide into 100 mL of alcohol-water solvent, ultrasonicate for 30 min, stir for 30 min to disperse, and obtain a mixed solution;

[0063] Dissolve 1 mmol of cobalt chloride in the above mixed solution, sonicate for 30 minutes, and stir at 5°C for 1 hour to obtain a uniform cobalt chloride mixed solution;

[0064] Add 20 mL of sodium borohydride solution with a concentration of 0.125 mol / L to the cobalt acetate mixed solution, and continue stirring at 5° C. for 10 min until it is completely reduced. Simultaneous precipitation;

[0065] Suction filter the above product, and then wash with distilled water for 3-4 times, the by-product sodium metaborate is dissolved in water and washed off to obtain the washed product;

[0066] The above-mentioned washed product was vacuum freeze-dried at -45°C to obtain GO@Co.

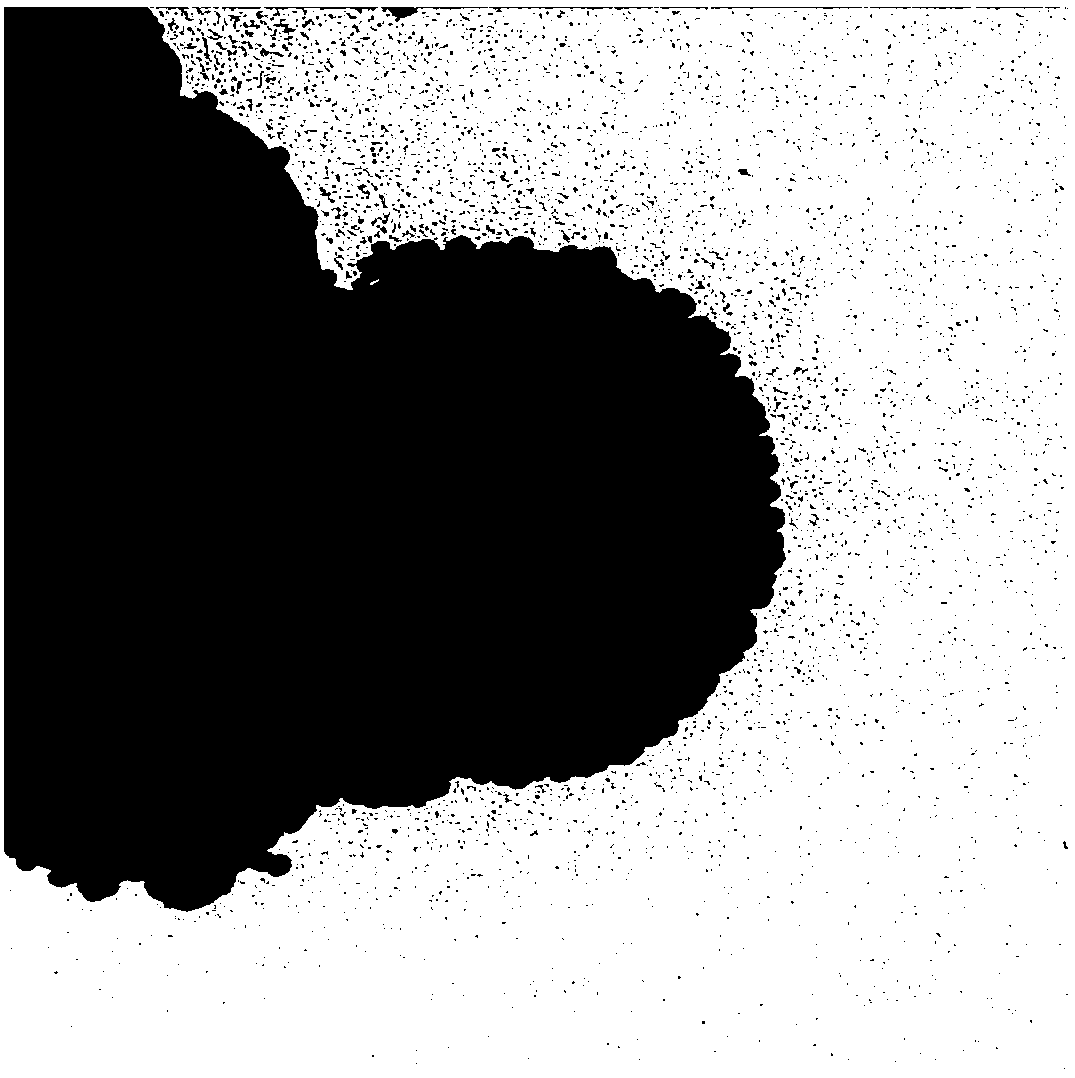

[0067] The GO@Co was characteriz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com