Highly-integrated multifunctional in-situ soil repairing complete apparatus and water treatment method thereof

An in-situ repair and complete equipment technology, applied in multi-stage water treatment, water/sewage treatment, special compound water treatment, etc., to achieve the effect of complete equipment functions, reduced equipment footprint, and convenient transportation and loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

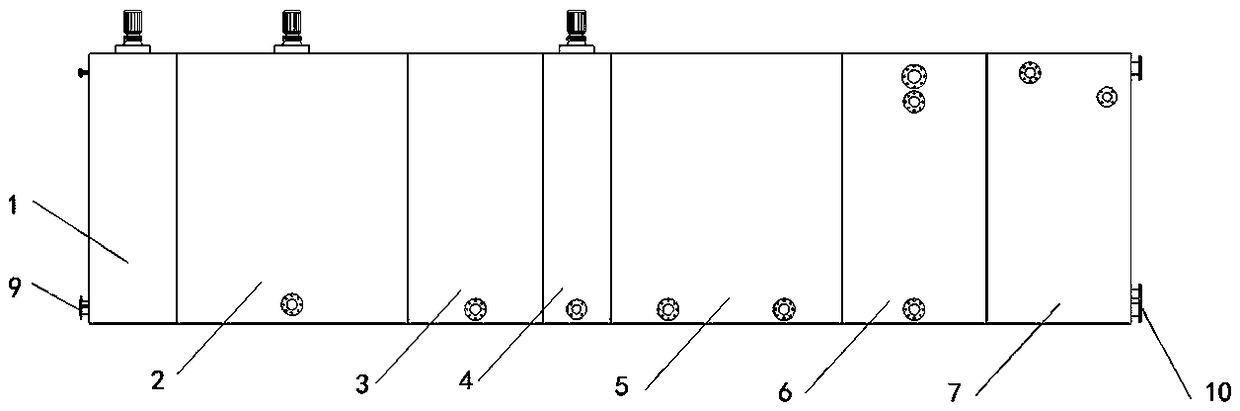

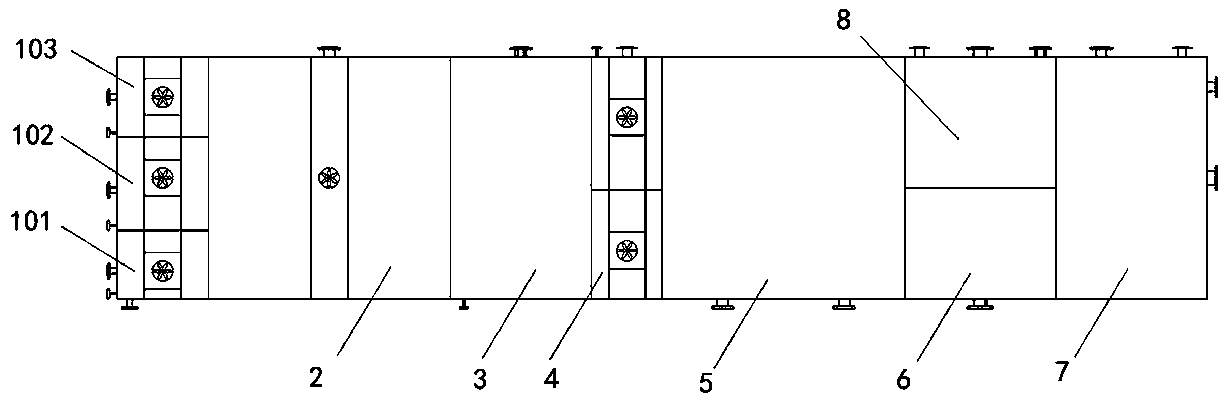

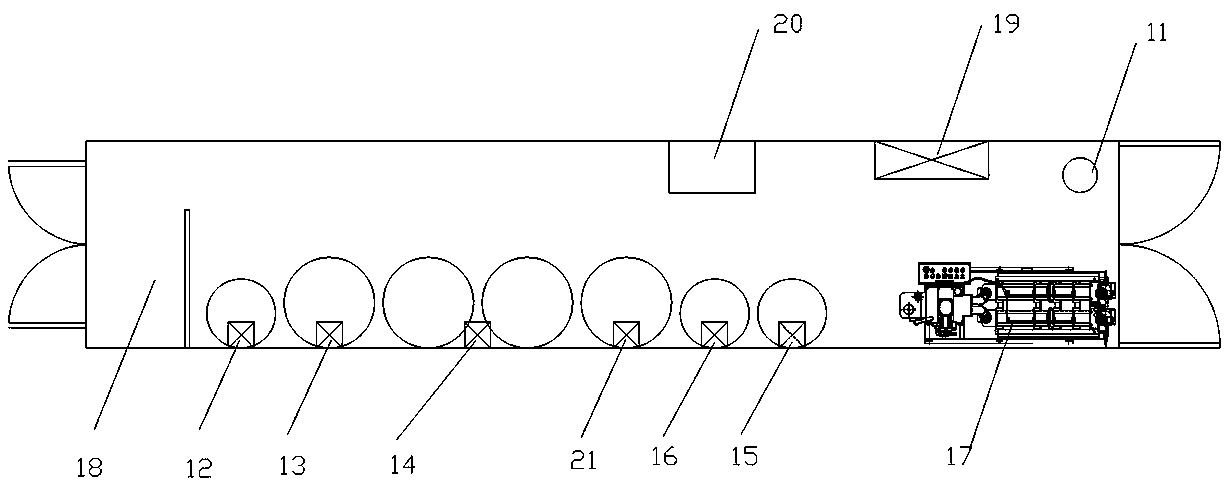

[0029] like Figure 1~3 The complete set of in-situ repairing soil equipment shown includes a main reaction tank and an integrated equipment room connected by steel wire hoses. The main reaction tank includes a dosing reaction chamber 1, a Fenton oxidation chamber 2, and a middle And reaction chamber 3, coagulation reaction chamber 4, inclined plate sedimentation chamber 5, sludge pond 6 and clear water pond 7, between described inclined plate sedimentation chamber 5 and clear water pond 7, be provided with the active carbon filter that links to each other in addition 8. The side wall of the dosing reaction chamber 1 is provided with a water inlet 9, and the side wall of the clear water tank is provided with a water outlet 10; the integrated equipment is provided with a self-cleaning system connected to the water inlet of the dosing reaction chamber. Filter 11 is connected to the sulfuric acid dosing device 12 of the dosing reaction chamber, the hydrogen peroxide dosing device...

Embodiment 2

[0031] Referring to Example 1, the main reaction tank is 2.0-2.8m wide and 2.4-3.2m high, and the wall of the main reaction tank is coated with a polyurea anti-corrosion layer.

Embodiment 3

[0033] Referring to Example 1, the sulfuric acid reaction chamber 101, the ferrous sulfate reaction chamber 102, the hydrogen peroxide reaction chamber 103, and the coagulation reaction chamber 4 are provided with a 316 material double paddle mixer for stirring; the Fenton The oxidation chamber 2 is equipped with a 316 material frame mixer for stirring; the neutralization reaction chamber 3 is equipped with a rotary aerator for aeration and stirring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com