Cu-MOF luminescent crystal material capable of realizing yellow light emission, and preparation method thereof

A technology of luminescent crystals and yellow light, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of high cost, environmental pollution, harsh preparation conditions, etc., and achieve the effect of low cost, good repeatability, and no pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

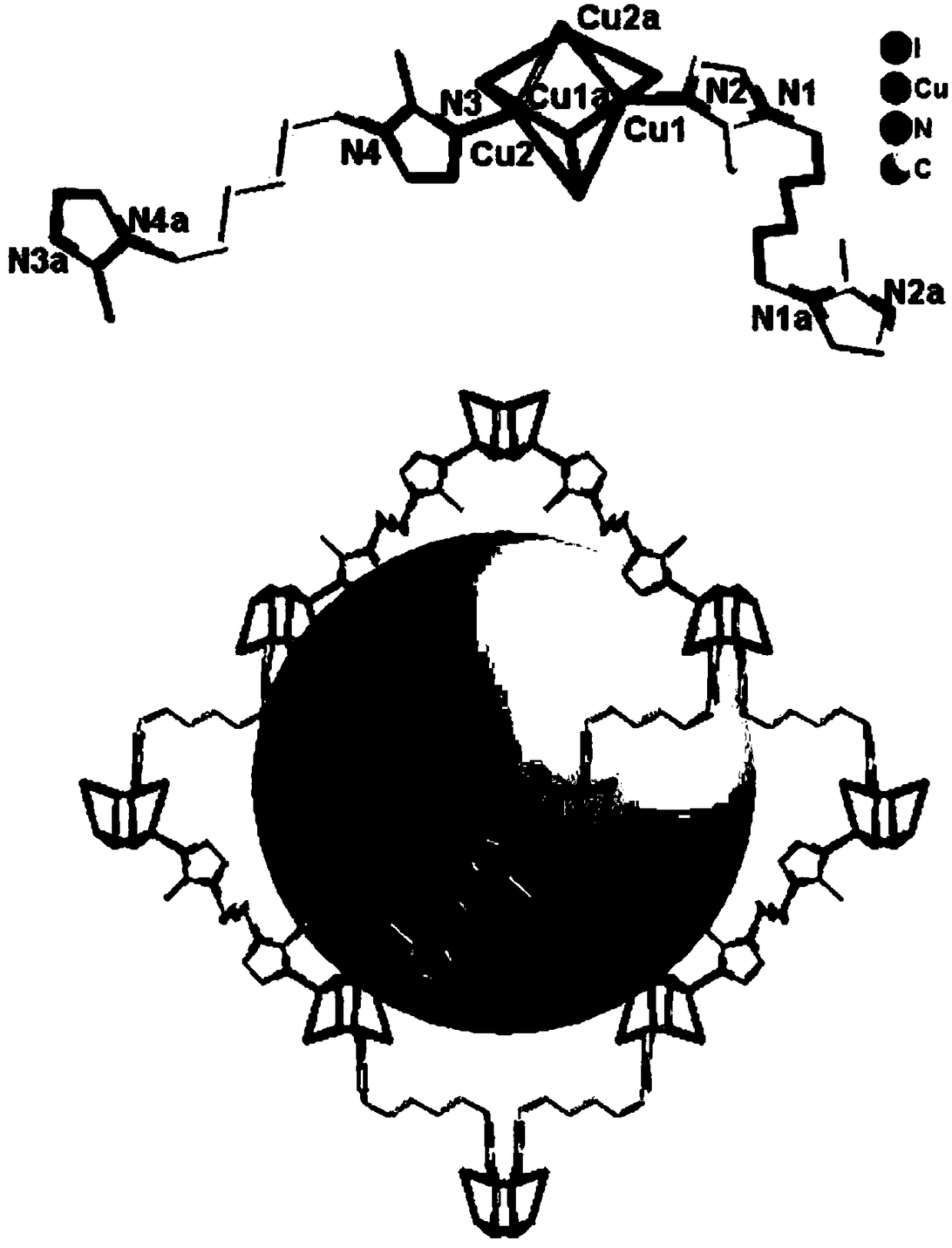

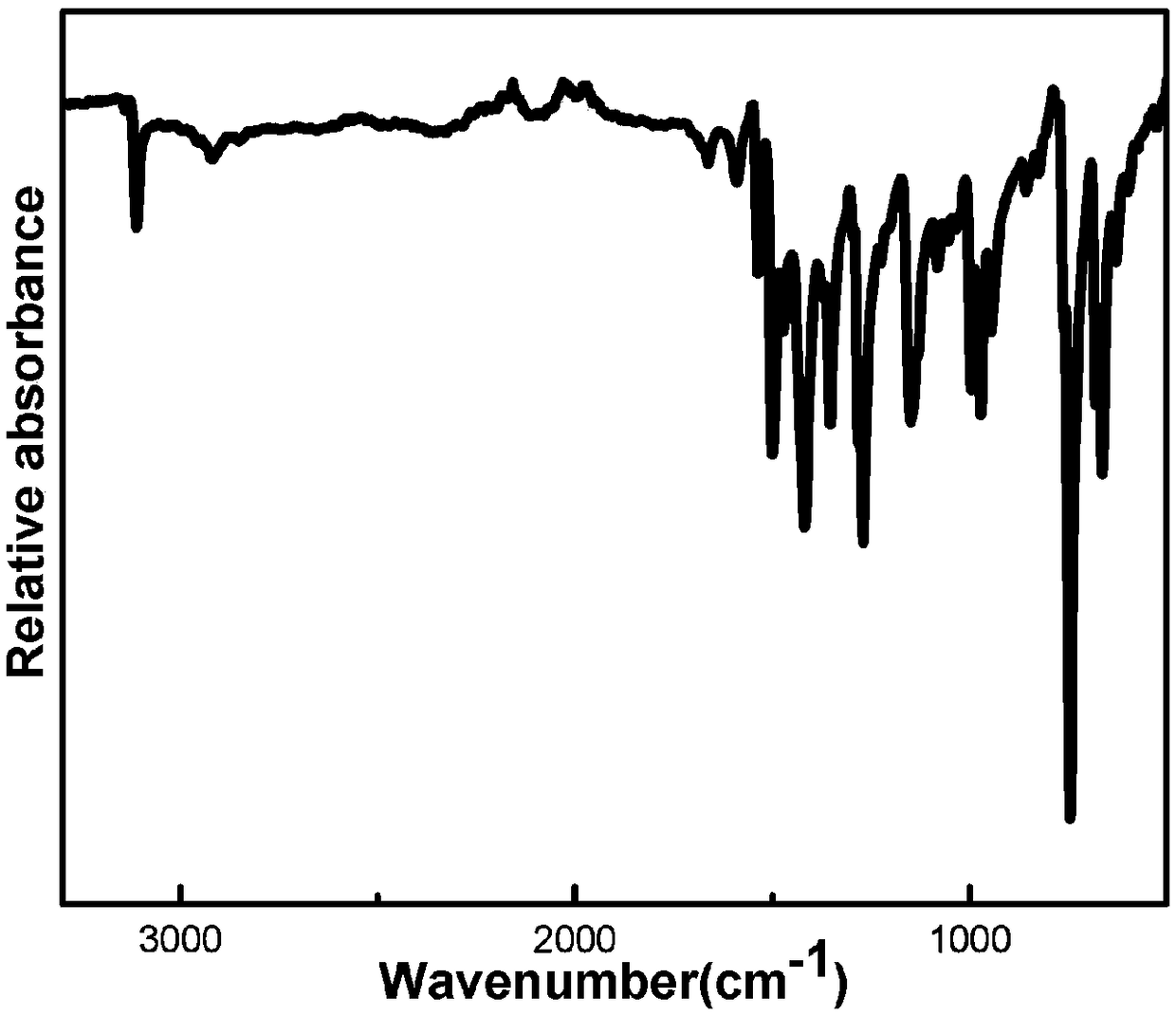

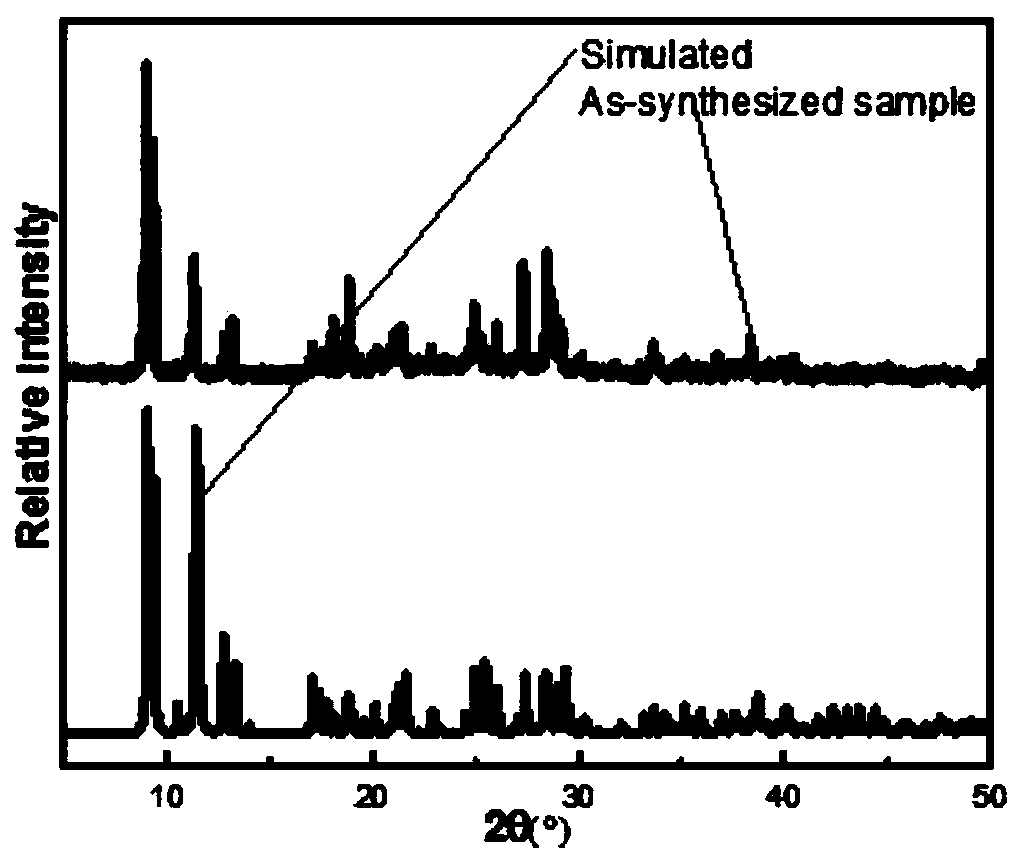

Image

Examples

Embodiment 1

[0026] Step 1. At room temperature, weigh 50mg CuI and 25.0mg 1,6-bis(2-methyl-1H-imidazol-1-yl)hexane, mix CuI and 1,6-bis(2-methyl-1H -Imidazol-1-yl)hexane was added to a 25ml autoclave equipped with 5ml of a mixed solvent consisting of deionized water, ethanol and DMF, wherein the volume ratio of deionized water, ethanol and DMF was 1:1:3 , stirred to obtain a uniformly mixed solution, then adjusted the pH value to 8 with 1ml of 0.01mol / L NaOH solution, and continued to stir for 5h to obtain a uniformly mixed solution.

[0027] Step 2. Keep the uniformly mixed solution at 100° C. for 24 hours.

[0028] Step 3, heat the solution after the above heat treatment at 5°C h -1 Cool down at the cooling rate until it cools down to room temperature.

[0029] Step 4, the mother liquor in the solution obtained in step 3 is removed, the solid obtained is washed with ethanol several times, and the brown transparent columnar crystal obtained is the product [Cu 2 (1,6-bis(2-methyl-1H-im...

Embodiment 2

[0034] Step 1. At room temperature, weigh 69.6mg CuI 2 and 45.0mg 1,6-bis(2-methyl-1H-imidazol-1-yl)hexane, CuI 2 and 1,6-bis(2-methyl-1H-imidazol-1-yl)hexane were added to an autoclave containing 10ml of a mixed solvent consisting of 25ml of deionized water, ethanol and DMF, wherein the deionized water The volume ratio of , ethanol and DMF is 1:3:6, stir to obtain a uniformly mixed solution, then use 1ml 0.01mol / L NaOH solution) to adjust the pH value to 8.5, and continue stirring for 5h to obtain a uniformly mixed solution.

[0035] Step 2. Keep the uniformly mixed solution at 120° C. for 24 hours.

[0036] Step 3, heat the solution after the above heat treatment at 5°C h -1 Cool down at the cooling rate until it cools down to room temperature.

[0037] Step 4, remove the mother liquor in the solution obtained in step 3, wash the solid obtained multiple times with water, and the brown transparent columnar crystal obtained is the product [Cu 2 (1,6-bis(2-methyl-1H-imidazo...

Embodiment 3

[0041] Step 1. At room temperature, weigh 95.5mg CuI and 60.0mg 1,6-bis(2-methyl-1H-imidazol-1-yl)hexane, mix CuI and 1,6-bis(2-methyl- 1H-imidazol-1-yl) hexane was added to a 25ml autoclave equipped with 14ml of a mixed solvent consisting of deionized water, ethanol and DMF, wherein the volume ratio of deionized water, ethanol and DMF was 4:3: 7. Stir to obtain a uniformly mixed solution, then adjust the pH value to 9.5 with 1ml 25% ammonia water (or 1ml 0.01mol / L NaOH solution), and continue stirring for 5h to obtain a uniformly mixed solution.

[0042] Step 2. Keep the uniformly mixed solution at 140° C. for 24 hours.

[0043] Step 3, heat the solution after the above heat treatment at 15°C h -1 Cool down at the cooling rate until it cools down to room temperature.

[0044] Step 4, remove the mother liquor in the solution obtained in step 3, wash the solid obtained multiple times with water, and the brown transparent columnar crystal obtained is the product [Cu 2 (1,6-bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com