Eu<3+>-activated silicate-based red phosphor powder and preparation method thereof

A technology of red fluorescent powder and silicate, which is applied in chemical instruments and methods, luminescent materials, nanotechnology for materials and surface science, etc., to achieve the effects of low energy consumption, saving production costs, and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

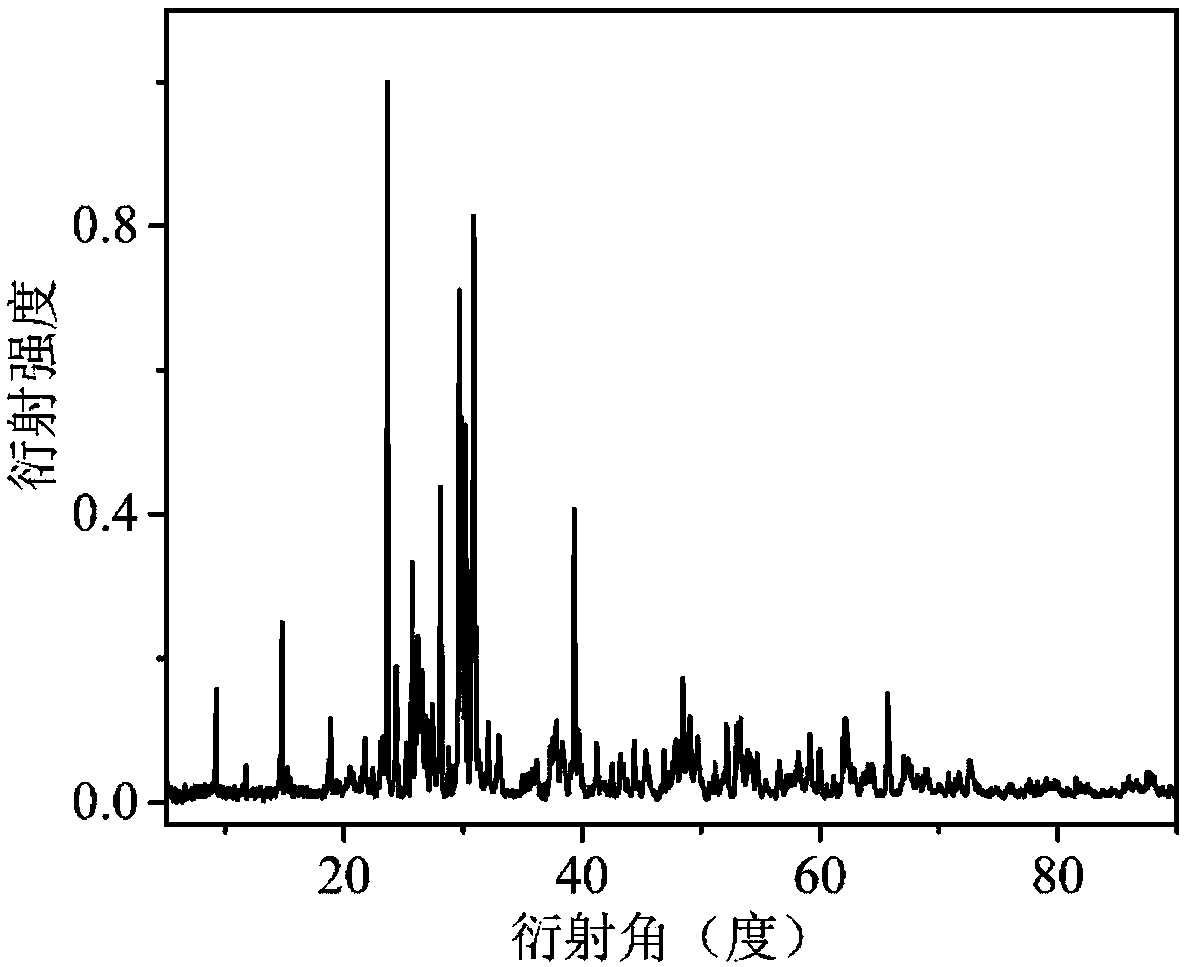

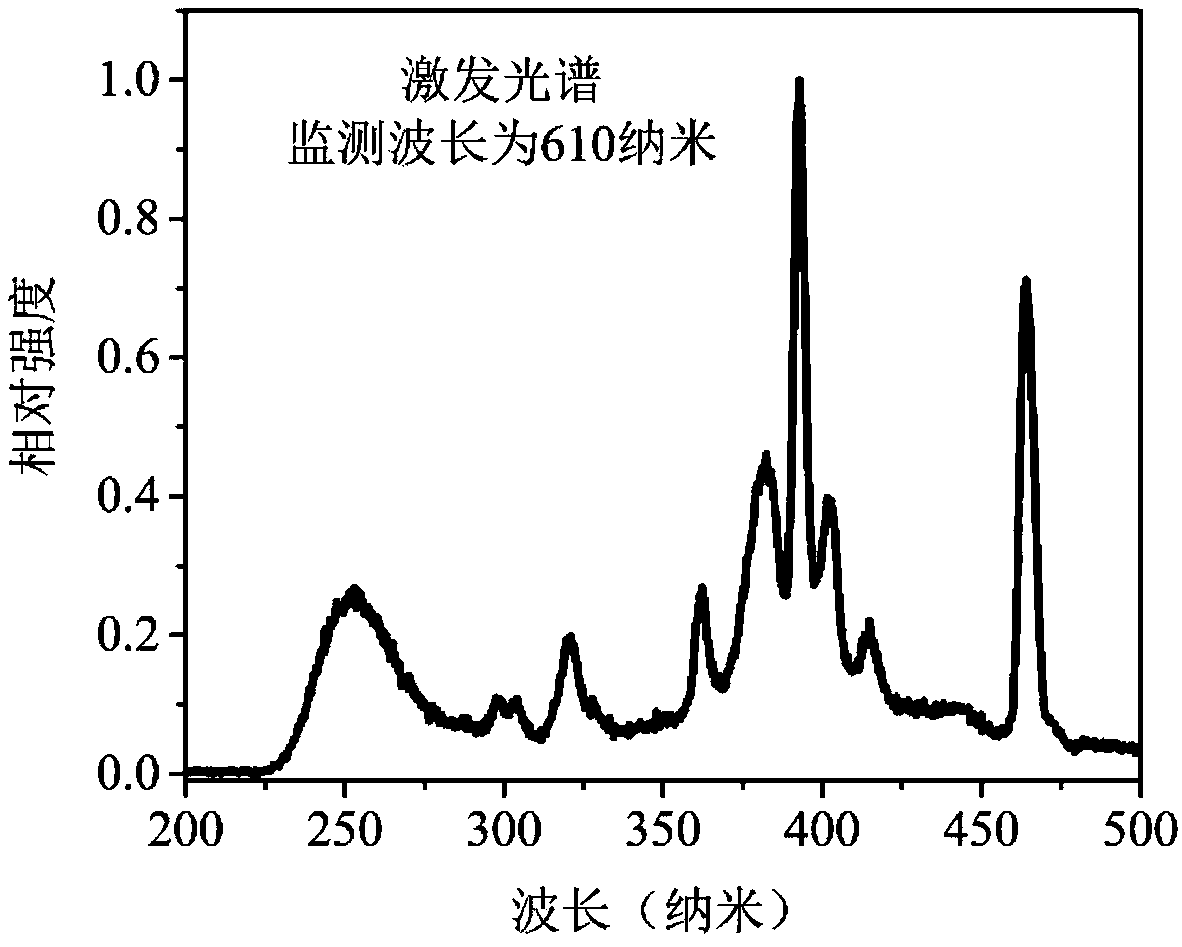

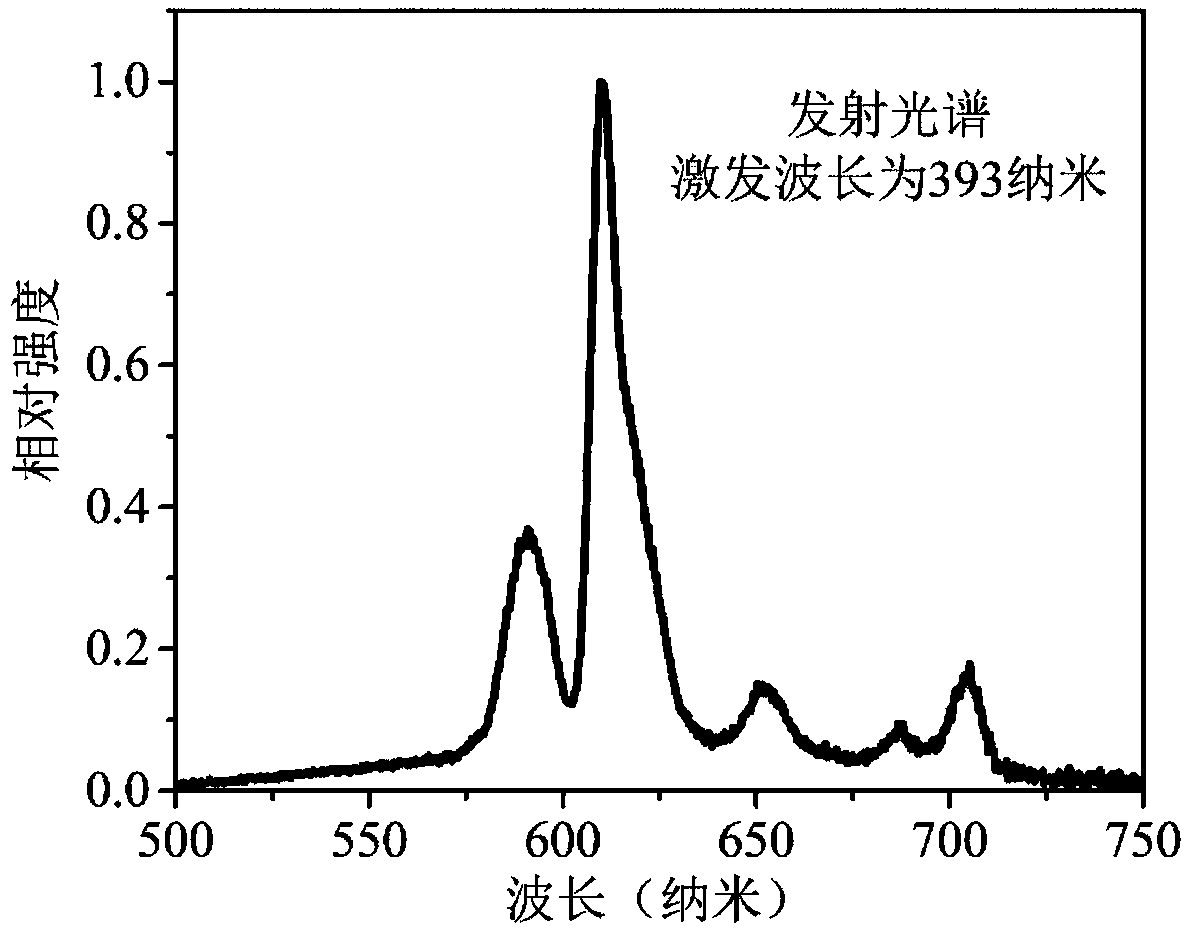

[0021] According to chemical formula Li 2 Ca 1.97 Eu 0.03 Si 5 o 13 The stoichiometric ratio of Li, Ca, and Eu elements in Li, respectively weighed lithium carbonate Li 2 CO 3 : 0.2803 g, calcium carbonate CaCO 3 : 0.7480 g, europium oxide Eu 2 o 3 : 0.0200 g, add dilute nitric acid solution, stir continuously until dissolved, then add citric acid: 9.5663 g to the solution, stir continuously, mix well, and obtain A solution; weigh ethyl orthosilicate: 3.9516 g, add appropriate amount of anhydrous Ethanol, stirred until completely dissolved to obtain solution B; mix solution A and solution B, and keep stirring in a water bath environment at 70°C until the solution becomes viscous and finally forms a transparent colloid; place the obtained colloid in In the oven, the temperature is 100°C, the time is 12 hours, aging and drying to obtain the precursor; the precursor is placed in the muffle furnace and calcined in the air atmosphere, the temperature is 400°C, the holding t...

Embodiment 2

[0027] According to chemical formula Li 2 Ca 1.999 Eu 0.001 Si 5 o 13 The stoichiometric ratio of Li, Ca, and Eu elements in Li, Ca, and Eu were weighed respectively as lithium nitrate LiNO 3 : 0.5192 grams, calcium hydroxide Ca(OH) 2 : 0.5576 g, europium nitrate Eu (NO 3 ) 3 ·6H 2O: 0.0017g, add dilute nitric acid solution, stir continuously until dissolved, then add oxalic acid: 4.0673g to the solution, stir continuously, mix well to obtain A solution; weigh ethyl orthosilicate: 3.9215g, add appropriate amount of anhydrous Ethanol, stirred until completely dissolved to obtain solution B; mix solution A and solution B, and keep stirring in a water bath environment at 60°C until the solution becomes viscous and finally forms a transparent colloid; place the obtained colloid in In the oven, the temperature is 90°C, the time is 12 hours, aging and drying to obtain the precursor; the precursor is placed in the muffle furnace and calcined in the air atmosphere, the tempera...

Embodiment 3

[0030] According to chemical formula Li 2 Ca 1.8 Eu 0.2 Si 5 o 13 For the stoichiometric ratio of Li, Ca, and Eu elements in Li, respectively weigh lithium hydroxide LiOH: 0.1686 g, calcium nitrate Ca (NO 3 ) 2 : 1.0399 g, europium oxide Eu 2 o 3 : 0.1239 grams, add dilute nitric acid solution, stir continuously until dissolved, then add 8.8786 grams of citric acid to the solution, stir continuously, mix evenly, and obtain A solution; weigh ethyl orthosilicate: 3.6676 grams, add appropriate amount of anhydrous Ethanol, stirred until completely dissolved to obtain solution B; mix solution A and solution B, and keep stirring in a water bath environment at 65°C until the solution becomes viscous and finally forms a transparent colloid; place the obtained colloid in In an oven, the temperature is 70°C, the time is 12 hours, aged and dried to obtain the precursor; the precursor is calcined in the air atmosphere in the muffle furnace, the temperature is 350°C, the holding tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com