A kind of method of extracting wheat germ compound oil

A wheat germ and compound oil technology, which is applied in the production of fat oil/fat, refining of fat oil/fat, and fat production, etc., can solve problems such as the inability to form industrialized large-scale production, the low nutritional value of edible oil products, and the lack of market competitive advantages for products. , to achieve the effect of less impurities, high content of natural nutrients and reducing oil loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

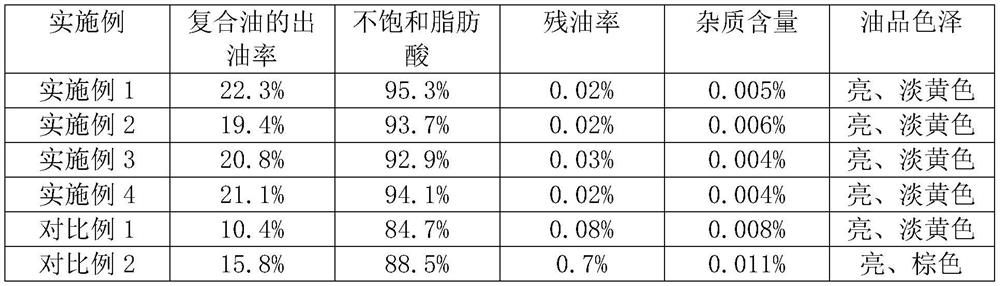

Examples

Embodiment 1

[0030] A method for extracting high-quality wheat germ compound oil, comprising the steps of:

[0031] (1) Pretreatment of raw materials: take the raw material wheat germ, dry it at 100°C for 20 minutes, and cool it to normal temperature for later use;

[0032] (2) Crushing of raw materials: put good quality and clean wheat germ, cleaned and peeled sesame seeds, and peanut kernels without red coat into the crushing tank, keep it at a temperature of 150°C and a pressure of 1.3MPa for 25 minutes, and then blast it instantly Obtain pulverized raw materials; wherein, the weight ratio of wheat germ to sesame and peanut kernels is 6:1:0.5;

[0033] (3) Microwave treatment: the raw material powder obtained in step (2) is irradiated for 80 seconds under a microwave environment of 1000 MHz;

[0034] (4) Compound enzymatic hydrolysis and oil extraction: take the raw material powder after microwave treatment in step (3), add water according to the ratio of mass ratio material: water = 1...

Embodiment 2

[0041] A method for extracting high-quality wheat germ compound oil, comprising the steps of:

[0042] (1) Pretreatment of raw materials: take the raw material wheat germ, dry it at 100°C for 20 minutes, and cool it to normal temperature for later use;

[0043](2) Crushing of raw materials: put good quality, clean wheat germ, cleaned and peeled sesame seeds, and peanut kernels without red coat into a crushing tank, keep it at a temperature of 145°C and a pressure of 1.5MPa for 25 minutes, and then blast it instantly Obtain pulverized raw materials; wherein, the weight ratio of wheat germ to sesame and peanut kernels is 8:1.5:0.7;

[0044] (3) Microwave treatment: the raw material powder obtained in step (2) is irradiated for 80 seconds under a microwave environment of 1100 MHz;

[0045] (4) Compound enzymatic hydrolysis and oil extraction: take the raw material powder after microwave treatment in step (3), add water according to the ratio of mass ratio material: water = 1:9, ...

Embodiment 3

[0052] A method for extracting high-quality wheat germ compound oil, comprising the steps of:

[0053] (1) Pretreatment of raw materials: take the raw material wheat germ, dry it at 100°C for 20 minutes, and cool it to normal temperature for later use;

[0054] (2) Crushing of raw materials: put good quality, clean wheat germ, cleaned, peeled sesame, and red-coated peanut kernels into a crushing tank, maintain it at a temperature of 160°C and a pressure of 1.2MPa for 15 minutes, and then explode instantly Obtain pulverized raw materials; wherein, the weight ratio of wheat germ to sesame and peanut kernels is 10:2:1;

[0055] (3) Microwave treatment: the raw material powder obtained in step (2) is irradiated for 80 seconds under a microwave environment of 1000 MHz;

[0056] (4) Compound enzymatic hydrolysis and oil extraction: take the raw material powder after microwave treatment in step (3), add water according to the ratio of mass ratio material: water = 1:8, then add cellu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com