A kind of extraction method of wheat germ compound oil

A technology of wheat germ and extraction method, which is applied in the field of extraction of wheat germ compound oil, can solve the problems of inability to form industrialized large-scale production, low nutritional value of edible oil products, and no market competitive advantage of products, so as to achieve easy control of production operations, The effect of high content of natural nutrients and less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

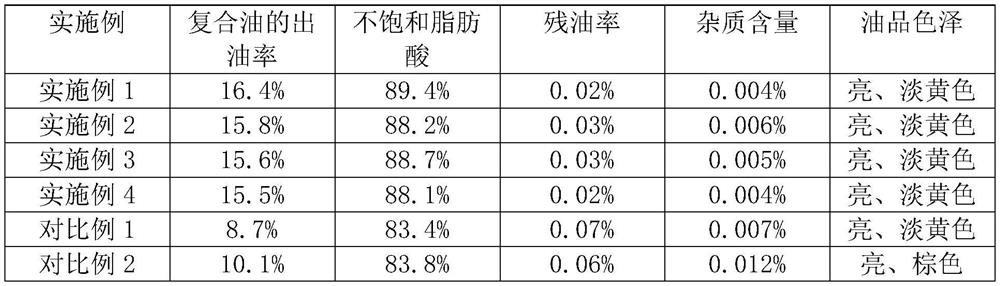

Examples

Embodiment 1

[0029] A method for extracting wheat germ compound oil, comprising the steps of:

[0030] (1) Grinding of raw materials: put good-quality, clean wheat germ and cleaned and peeled sesame seeds into a crushing tank, maintain it at a temperature of 150°C and a pressure of 1.3 MPa for 15 minutes, and then explode instantly to obtain crushed raw materials; among them, The weight ratio of wheat germ to sesame is 6:1;

[0031] (2) Microwave treatment: the raw material powder obtained in step (1) is irradiated for 80 seconds under a microwave environment of 1000 MHz;

[0032] (3) Compound enzymatic hydrolysis and oil extraction: take the raw material powder after microwave treatment in step (2), add water according to the ratio of mass ratio material: water = 1:10, then add cellulase, neutral protease and ALCALASE2.4L The compound enzyme of protease is hydrolyzed, the enzymolysis temperature is 45°C, and the enzymolysis time is 5h; after the enzymolysis is completed, centrifuge at a ...

Embodiment 2

[0039] A method for extracting wheat germ compound oil, comprising the steps of:

[0040] (1) Grinding of raw materials: put good-quality, clean wheat germ and cleaned and peeled sesame seeds into a crushing tank, maintain it at a temperature of 1450°C and a pressure of 1.5 MPa for 15 minutes, and then explode instantly to obtain crushed raw materials; among them, The weight ratio of wheat germ to sesame is 8:1.3;

[0041] (2) Microwave treatment: the raw material powder obtained in step (1) is irradiated for 80 seconds under a microwave environment of 1100 MHz;

[0042] (3) Compound enzymatic hydrolysis and oil extraction: take the raw material powder after microwave treatment in step (2), add water according to the ratio of mass ratio material: water = 1:9, then add cellulase, papain and ALCALASE2.4L protease hydrolysis with compound enzymes, the enzymolysis temperature is 50°C, and the enzymolysis time is 5h; after the enzymolysis, centrifuge for 25min at a centrifugal spe...

Embodiment 3

[0049] A method for extracting wheat germ compound oil, comprising the steps of:

[0050] (1) Grinding of raw materials: put good-quality, clean wheat germ and cleaned and peeled sesame seeds into a crushing tank, maintain at a temperature of 160°C and a pressure of 1.2 MPa for 15 minutes, and then blast instantly to obtain crushed raw materials; among them, The weight ratio of wheat germ to sesame is 9:1.5;

[0051] (2) Microwave treatment: the raw material powder obtained in step (1) is irradiated for 80 seconds under a microwave environment of 1000 MHz;

[0052] (3) Compound enzymatic hydrolysis and oil extraction: take the raw material powder after microwave treatment in step (2), add water according to the ratio of mass ratio material: water = 1:8, and then add cellulase, neutral protease and ALCALASE2.4L The compound enzyme of protease is hydrolyzed, the enzymolysis temperature is 45°C, and the enzymolysis time is 5h; after the enzymolysis is completed, centrifuge at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com